In a significant stride towards enhancing energy efficiency and material protection, researchers from Huaxin Cement Co., Ltd., and the Hubei Key Lab of Green Low-Carbon Cement in Wuhan, China, have developed a novel superhydrophobic thermal insulation coating. This innovation, detailed in a study published in *Cailiao Baohu* (translated as *Materials Protection*), addresses critical limitations of traditional coatings, paving the way for broader applications in the energy sector and beyond.

The research, led by Jiang Songtao and colleagues, introduces a composite aerogel with a unique “ball-stick” network structure, combining halloysite nanotubes (HNTs) and silicon dioxide (SiO₂). This structure is achieved through a sol-gel method, followed by supercritical CO₂ drying, resulting in a material that is both lightweight and robust. The coating is then prepared by mixing the ground composite with an aqueous polyurethane dispersion and a low-surface-energy substance, 1H,1H,2H,2H-perfluorodecyltriethoxysilane, before being sprayed onto substrates.

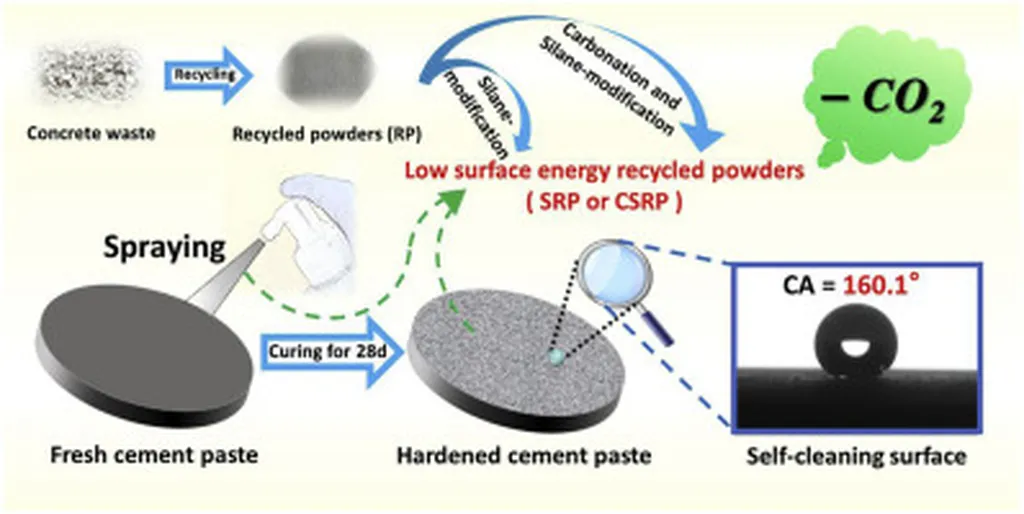

The study’s findings are promising. When the HNTs content was optimized to 25% by mass, the coating exhibited exceptional properties: a water contact angle of 160.8°, a rolling angle of just 3.1°, and a remarkably low thermal conductivity of 0.045 W/(m·K). Even after 20 wear cycles, the water contact angle remained high at 152.5°, demonstrating the coating’s durability and wear resistance.

“These results indicate that our coating can be applied to a variety of soft and hard substrates, providing excellent protection against contamination and damage from oil, mold, and other pollutants,” said Jiang Songtao, the lead author of the study.

The implications for the energy sector are substantial. Superhydrophobic thermal insulation coatings can significantly reduce energy consumption by minimizing heat loss, thereby enhancing the efficiency of buildings and industrial equipment. Additionally, the coating’s resistance to wear and contamination can extend the lifespan of materials, reducing maintenance costs and environmental impact.

“This research opens up new possibilities for energy-efficient and durable materials,” added Jiang. “The potential applications are vast, from industrial pipelines to building insulation, offering a sustainable solution for energy conservation.”

The study’s publication in *Cailiao Baohu* underscores its relevance to materials science and engineering, providing a foundation for future developments in the field. As the demand for energy-efficient and environmentally friendly materials grows, innovations like this coating could play a pivotal role in shaping the future of the energy sector and beyond.

In an era where sustainability and efficiency are paramount, this research offers a glimpse into the potential of advanced materials to revolutionize how we protect and insulate our infrastructure. As the world seeks to reduce energy consumption and environmental impact, such breakthroughs are not just welcome but essential.