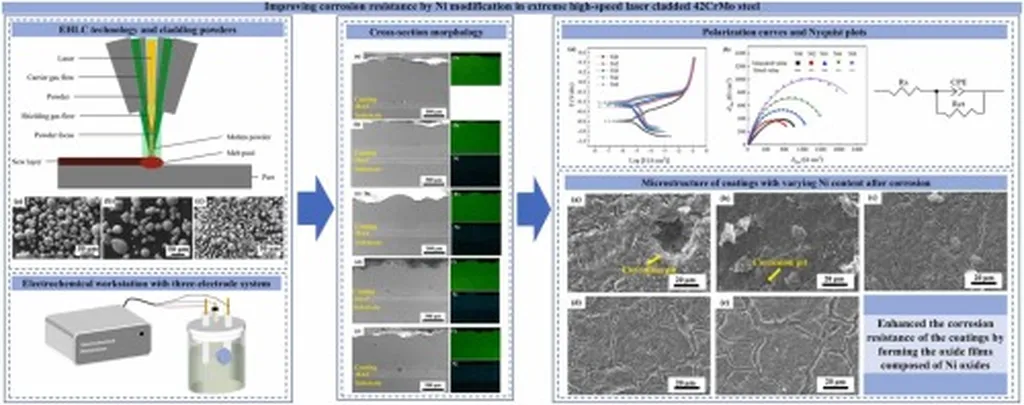

In the quest to extend the lifespan of critical components in industrial applications, a team of researchers from Ningbo University and Ningbo Steel Co., Ltd. has made significant strides using ultra-high-speed laser cladding technology. Led by Dr. ZHANG Jianyuan, the team’s work on 42CrMo steel coatings, published in the journal ‘Cailiao Baohu’ (which translates to ‘Materials Protection’), offers promising insights for the energy sector and beyond.

42CrMo, a traditional structural steel known for its low cost, is widely used in various industrial applications. However, its surface erosion under complex service conditions often limits the service life of components. To address this, the researchers explored the effects of varying laser powers (3.0 to 4.0 kW) on the microstructure and properties of 42CrMo coatings deposited on Q235 substrates.

The study revealed that laser power plays a pivotal role in determining the coating’s microstructure. As the power increased, internal defects such as cracks and pores were significantly reduced. “The increase in laser power not only improved the coating’s structural integrity but also influenced its mechanical and corrosion-resistant properties,” noted Dr. ZHANG Jianyuan, the lead author of the study.

The team observed that as the laser power increased from 3.0 kW to 4.0 kW, the dilution rate rose from 0.15% to 0.27%, and the average grain size coarsened from 2.18 μm to 3.73 μm. This grain coarsening led to a decrease in microhardness from 486 HV to 452 HV. Additionally, the corrosion resistance of the coating decreased with increasing laser power. At 3.0 kW, the coating exhibited the lowest self-corrosion current density and the highest impedance value, indicating superior corrosion resistance.

The findings are particularly relevant for the energy sector, where the longevity of components is crucial for operational efficiency and safety. “Understanding the impact of laser power on coating properties allows us to optimize the laser cladding process, enhancing the performance and durability of critical components,” explained Dr. HAN Yanbin, a co-author of the study.

The research provides fundamental experimental data for the application of 42CrMo steel in ultra-high-speed laser cladding, offering valuable insights for optimizing process parameters and improving coating surface quality. As the energy sector continues to evolve, such advancements in material science and coating technologies will be instrumental in developing more robust and long-lasting components, ultimately driving efficiency and sustainability in industrial applications.

The study, published in ‘Cailiao Baohu’, underscores the importance of tailored laser cladding processes in enhancing the performance of structural steels. By fine-tuning the laser power, manufacturers can achieve coatings with superior mechanical properties and corrosion resistance, paving the way for more reliable and durable industrial components. This research not only advances our understanding of laser cladding technology but also opens new avenues for innovation in the energy sector and beyond.