In the quest to mitigate carbon emissions, the energy sector is increasingly turning to Carbon Capture, Utilization, and Storage (CCUS) technologies. However, the harsh environments within these systems present significant challenges, particularly when it comes to material degradation. A recent study published in *Cailiao Baohu* (translated as *Materials Protection*) sheds light on how oxygen influences the corrosion behavior of 13Cr martensitic stainless steel, a material commonly used in CCUS applications. The research, led by ZHAO Guoxian from Xi’an Shiyou University and Xi’an Maurer Petroleum Engineering Laboratory Co., Ltd., offers critical insights that could shape future material choices and corrosion mitigation strategies in the energy sector.

The study employed high-temperature, high-pressure autoclave experiments to simulate CCUS storage conditions, comparing the corrosion behavior of 13Cr martensitic stainless steel under both aerobic and anaerobic environments. Using a suite of analytical techniques—including weight loss measurements, scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS), X-ray diffraction (XRD), and electrochemical methods—the researchers uncovered significant differences in corrosion behavior.

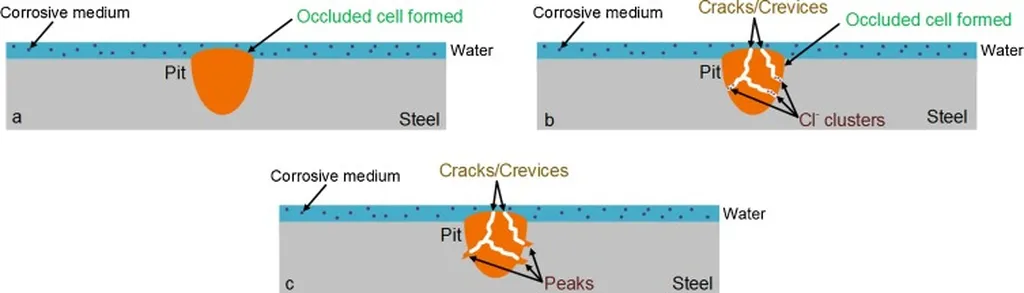

Under anaerobic conditions, the corrosion products primarily consisted of Cr2O3, Cr(OH)3, and FeCO3, forming a relatively stable and protective layer. However, the introduction of oxygen dramatically altered this scenario. “Oxygen significantly accelerated the corrosion of 13Cr martensitic stainless steel,” noted ZHAO Guoxian, the lead author. Under aerobic conditions, the corrosion products were loose, porous iron oxides with poor adhesion, leading to a rough and unstable surface.

Electrochemical analyses revealed that the corrosion product films exhibited semi-passivation behavior under both conditions, but with notable differences. Under anaerobic conditions, the films showed over-passivation and secondary passivation, indicating a more protective layer. In contrast, aerobic conditions led to a negative shift in the self-corrosion potential, suggesting a less stable and more reactive surface.

Electrochemical impedance spectroscopy (EIS) further highlighted the detrimental effects of oxygen. The presence of oxygen decreased the resistance of the corrosion product films and the charge transfer resistance, increasing surface roughness and accelerating charge transfer. This facilitated a shift in the cathodic reaction from hydrogen evolution to oxygen absorption corrosion, exacerbating the overall corrosion process.

Mott-Schottky analyses provided additional insights, revealing that the corrosion product film acted as a bipolar n-p type semiconductor. Under aerobic conditions, the carrier concentration increased, while the stability of the film decreased. “The strong oxidizing property of oxygen caused the oxidation of Fe2+ to Fe3+, inhibiting the formation of Cr(OH)3 and FeCO3, leading to a loose corrosion product layer with a rough surface,” explained ZHAO.

The implications of this research are profound for the energy sector. As CCUS technologies become more prevalent, understanding and mitigating corrosion in these environments will be crucial for ensuring the longevity and efficiency of storage systems. The findings suggest that while 13Cr martensitic stainless steel is a viable option, its performance can be significantly compromised in the presence of oxygen. This underscores the need for advanced materials or protective coatings that can withstand the dual challenges of CO2 and O2 corrosion.

For industry professionals, this research serves as a wake-up call to reevaluate material choices and corrosion mitigation strategies. As ZHAO Guoxian emphasized, “The results highlight the critical role of oxygen in accelerating corrosion and the importance of developing materials that can resist these harsh conditions.” By addressing these challenges head-on, the energy sector can move closer to achieving more sustainable and efficient CCUS solutions.

Published in *Cailiao Baohu*, this study not only advances our scientific understanding but also provides a practical roadmap for future developments in material science and corrosion engineering. As the energy sector continues to evolve, such research will be instrumental in shaping the technologies and strategies that will define the future of carbon capture and storage.