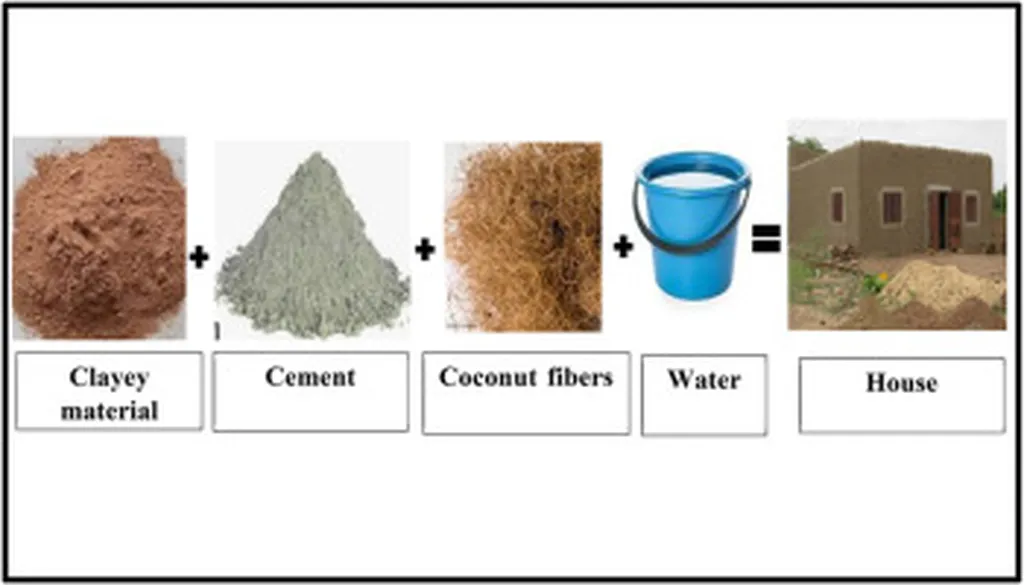

In the rugged Andean highlands, where traditional construction methods have stood the test of time, a groundbreaking study is poised to redefine the future of rural housing. Researchers from the Faculty of Civil Engineering at Continental University in Huancayo, Peru, have uncovered a novel approach to enhance the performance of adobe, a material that has long been the backbone of local architecture. The study, led by Russell Jeanpierre Laureano Hurtado, explores the combined use of coconut fiber and expired cement to bolster the physical, mechanical, and thermal properties of adobe blocks, offering a sustainable and cost-effective solution for resilient construction.

Adobe, while environmentally friendly and locally available, has historically faced criticism for its high water absorption, moderate mechanical strength, and insufficient durability. These limitations have constrained its use in more demanding construction applications. However, the recent findings published in the *Journal of the Civil Engineering Forum* (known in English as the *Journal of the Civil Engineering Forum*) suggest that these challenges can be effectively addressed through innovative material modifications.

The research team systematically evaluated the impact of adding coconut fiber and expired cement to adobe mixtures. By varying the concentrations of these additives, they discovered that the optimal combination—0.9% coconut fiber and 9% expired cement—yielded remarkable improvements. The compressive strength of the adobe blocks nearly doubled, reaching 37.86 kg.cm-2, compared to 17.69 kg.cm-2 for the control sample. “This significant enhancement in mechanical strength opens up new possibilities for adobe construction, making it a viable option for more robust and durable structures,” Hurtado explained.

Beyond mechanical strength, the study also highlighted substantial improvements in other critical properties. Water absorption decreased to 7.82%, reducing the risk of moisture-related damage and enhancing the material’s longevity. Thermal conductivity was reduced to 0.52 W.m-1.K-1, indicating better insulation properties that could lead to energy savings in the long run. “The thermal performance of the improved adobe is particularly noteworthy,” Hurtado added. “It not only enhances comfort but also aligns with the growing demand for energy-efficient building materials.”

Economically, the improved adobe presented a unit cost of S/ 154.14 per m2, which is 27% higher than the control sample. However, the researchers argue that the long-term benefits, such as increased durability and reduced maintenance costs, justify the initial investment. “While the upfront cost is slightly higher, the overall performance gains make it a cost-effective solution for rural housing,” Hurtado noted.

The implications of this research extend beyond the Andean highlands. As the construction industry increasingly seeks sustainable and locally sourced materials, the findings offer a blueprint for enhancing traditional building techniques with modern innovations. The use of expired cement, which is often discarded, not only reduces waste but also provides a practical solution for construction in resource-limited areas.

Looking ahead, this study could pave the way for further research into the use of alternative fibers and additives to improve the performance of traditional building materials. The potential for scaling these techniques could revolutionize construction practices in regions where adobe is prevalent, offering a sustainable and resilient alternative to conventional materials.

In the words of Hurtado, “This research is just the beginning. We hope to inspire further exploration into the potential of combining traditional knowledge with modern innovations to create better, more sustainable construction materials.” As the world grapples with the challenges of climate change and resource scarcity, such innovations are not just welcome but essential.