In the quest for sustainable construction materials, a recent study has uncovered a promising blend that could revolutionize the way we build, particularly in harsh climates. Xiaoqing Wang, from the Department of Architecture and Engineering at Wuhan City Polytechnic in China, has been exploring the synergistic effects of silica fume and basalt fibers on recycled concrete, with a focus on mechanical performance and freeze-thaw durability.

The research, published in the journal *Materials Research Express* (translated as *Express for Materials Research*), delves into the potential of combining silica fume (SF) and short-cut basalt fibers (BF) to enhance the properties of recycled concrete. This is not just about creating stronger materials; it’s about extending the life of structures in freezing environments, which is a game-changer for the energy sector, especially in cold regions.

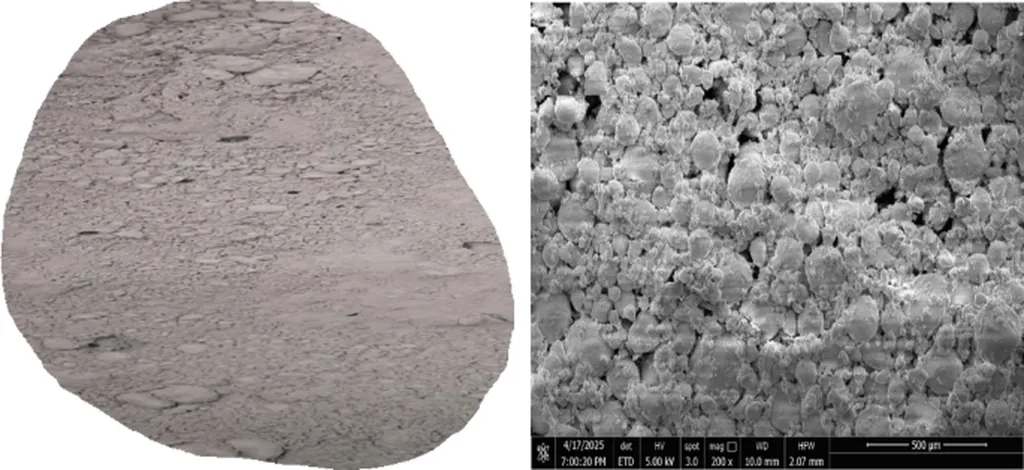

Wang and his team prepared recycled concrete mixtures with varying contents of SF (0, 5%, 10%, and 15%) and BF (0, 0.5%, 1.0%, and 1.5%). They conducted compressive and flexural strength tests, along with durability evaluations after 50, 100, and 150 freeze-thaw cycles. The results were striking. “The appropriate incorporation of SF and BF significantly refined the interfacial transition zone, improved matrix densification, and enhanced crack resistance,” Wang explained. This led to a substantial increase in compressive and flexural strength, with the optimal mix reaching 53.7 MPa and 6.09 MPa, respectively.

The freeze-thaw tests revealed that the combination of 10% SF and 1.0% basalt fiber achieved the best strength retention and structural integrity after 150 cycles. This is a significant finding for the construction industry, particularly for structures in cold climates where freeze-thaw cycles can cause considerable damage over time.

One of the most innovative aspects of this research is the development of a response surface methodology (RSM)-based multivariate regression model for performance prediction. This model exhibited high fitting accuracy and predictive reliability, with the optimal mix predicted at 10.51% SF and 0.96% basalt fiber, closely matching the experimental results.

So, what does this mean for the future of construction? The synergistic incorporation of SF and BF not only enhances the mechanical and frost resistance properties of recycled concrete but also promotes the sustainable utilization of industrial by-products. This aligns with the growing trend towards low-carbon construction practices, which are increasingly important in the energy sector.

As Wang’s research demonstrates, the future of construction lies in the innovative use of recycled materials and industrial by-products. By enhancing the properties of recycled concrete, we can build stronger, more durable structures that are also environmentally friendly. This is not just a win for the construction industry; it’s a win for the planet.

In the words of Wang, “This research opens up new possibilities for the sustainable utilization of industrial by-products in construction, contributing to low-carbon practices and enhancing the durability of structures in harsh climates.” As the energy sector continues to evolve, the demand for sustainable and durable construction materials will only grow, making this research a significant step forward in the field.