In a significant stride towards sustainable materials in the energy sector, researchers have demonstrated that partially replacing carbon black (CB) with talc in natural rubber (NR) compounds can enhance processing and dynamic performance without compromising key mechanical properties. The study, led by Hatay Cöcen, was recently published in the journal *eXPRESS Polymer Letters*, which translates to *Polymer Letters Express* in English.

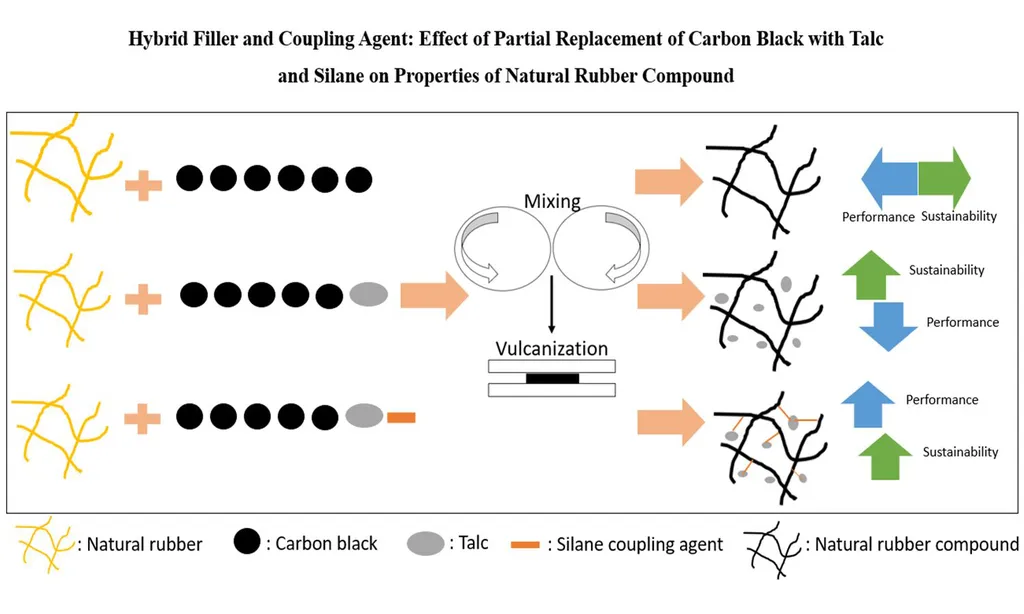

The research explores a hybrid filler strategy that not only reduces reliance on petroleum-based CB but also introduces a silane coupling agent to improve interfacial compatibility. This innovation could have profound implications for industries reliant on durable, high-performance elastomers, including energy and automotive sectors.

“By partially replacing carbon black with talc and incorporating a silane coupling agent, we observed a significant reduction in compound viscosity, which offers substantial processing benefits,” said Hatay Cöcen. This reduction in viscosity can lead to more efficient manufacturing processes, potentially lowering energy consumption and costs.

The study revealed that while talc decreased the crosslink density of the NR compounds, the addition of silane effectively recovered it by forming covalent linkages. This dual approach not only improved tensile strength and elongation at break but also maintained the hardness of the material. Dynamically, talc initially increased heat build-up, but the introduction of silane reversed this trend, gradually reducing the temperature rise from 41.5 to 29.4°C at 2 parts per hundred rubber (phr).

One of the most notable findings was the improvement in fatigue life. The researchers observed a 10% increase with talc alone, and an additional 36% improvement with the inclusion of silane at 2 phr. This suggests a favorable balance between stiffness and fatigue resistance, which is crucial for applications requiring long-term durability.

The research highlights the potential for significant sustainability gains in the energy sector, where natural rubber compounds are widely used in various applications, from seals and gaskets to hoses and belts. By reducing the reliance on petroleum-based fillers and enhancing performance through compatibilization, this study paves the way for more eco-friendly and efficient materials.

As the energy sector continues to evolve, the demand for sustainable and high-performance materials will only grow. This research offers a promising avenue for achieving these goals, potentially shaping future developments in material science and engineering.

The findings were published in *eXPRESS Polymer Letters*, a renowned journal in the field of polymer science, underscoring the significance of this work in advancing sustainable practices in the energy sector.