In the rapidly evolving world of construction technology, 3D printing has emerged as a game-changer, promising to revolutionize the way we build. But as with any innovative technology, questions about durability and long-term performance linger. A recent study published in the journal *Civil and Environmental Engineering* (translated from Czech as “Civil and Environmental Engineering”) by Karel Hurtig of the Klokner Institute at the Czech Technical University in Prague, sheds light on these critical aspects, offering valuable insights for the construction and energy sectors.

The study, titled “Experimental Assessment of Durability in 3D Printed Cementitious Materials,” focuses on evaluating the long-term durability of 3D printed cement-based composites. Hurtig and his team subjected these materials to a series of rigorous tests, including resistance to water and chemical de-icing agents, freeze-thaw resistance, water absorption, depth of water penetration under pressure, and carbonation depth after long-term exposure to outdoor environmental conditions.

One of the key findings of the study is the significant impact of mixture composition on durability performance. “The presence of a setting accelerator and dispersed steel reinforcement played a crucial role in enhancing the material’s durability,” Hurtig explains. This is particularly relevant for the energy sector, where structures often face harsh environmental conditions and require robust, long-lasting materials.

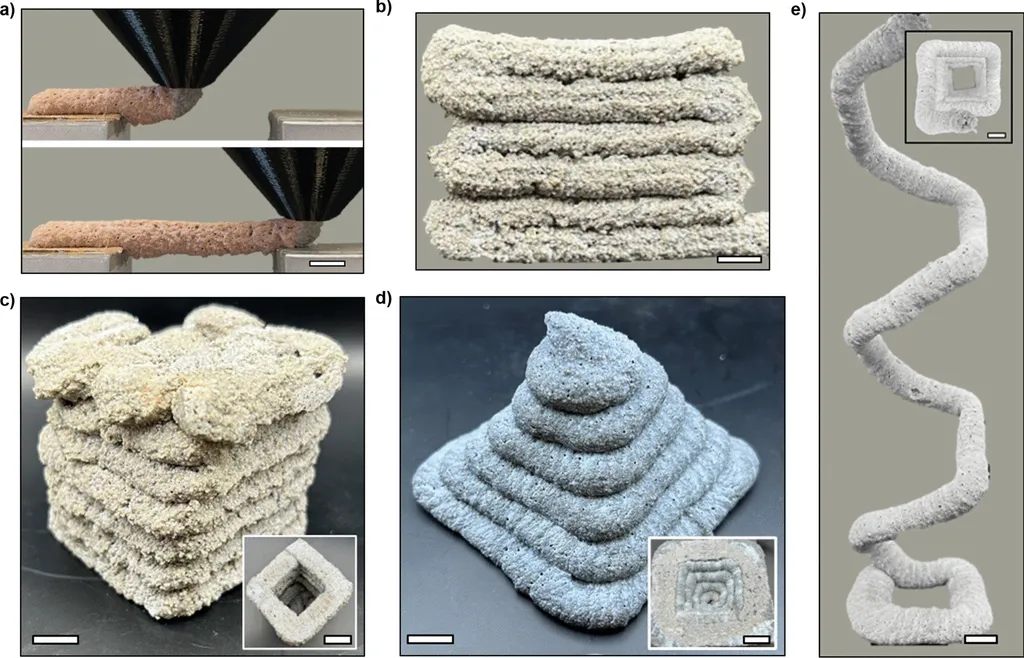

The research also highlights the unique aspects of durability behavior arising from the layered structure of 3D printed materials. This understanding is vital for optimizing the design and construction processes to ensure the longevity of 3D printed structures.

The implications of this study are far-reaching. As the construction industry increasingly adopts 3D printing technology, the findings provide a crucial benchmark for assessing the durability of printed materials. This knowledge is essential for developers, engineers, and architects aiming to leverage 3D printing for large-scale projects, including those in the energy sector.

Moreover, the study underscores the importance of tailored material compositions to enhance durability. This could lead to the development of new, high-performance cementitious materials specifically designed for 3D printing, further expanding the applications of this innovative technology.

As Hurtig notes, “Our research is just the beginning. The field of 3D printed cementitious materials is ripe for exploration, and we are excited to contribute to its growth and development.” With ongoing advancements in 3D printing technology and material science, the future of construction looks set for a transformative shift, driven by innovation and a deeper understanding of material behavior.

For professionals in the construction and energy sectors, staying informed about these developments is crucial. The insights gained from this study not only enhance our understanding of 3D printed materials but also pave the way for more sustainable, efficient, and durable construction practices. As the industry continues to evolve, the integration of 3D printing technology holds the promise of a more resilient and innovative built environment.