In the heart of Poland, researchers are pushing the boundaries of plasma spraying technology, and their latest findings could have significant implications for the energy sector. Tadeusz Kubaszek, a scientist from the Research and Development Laboratory for Aerospace Materials at Rzeszow University of Technology, has been exploring the effects of plasma spraying parameters on the microstructure of coatings made of Stellite 31, a highly durable cobalt-chromium alloy, doped with YSZ (Yttria-Stabilized Zirconia) ceramic particles.

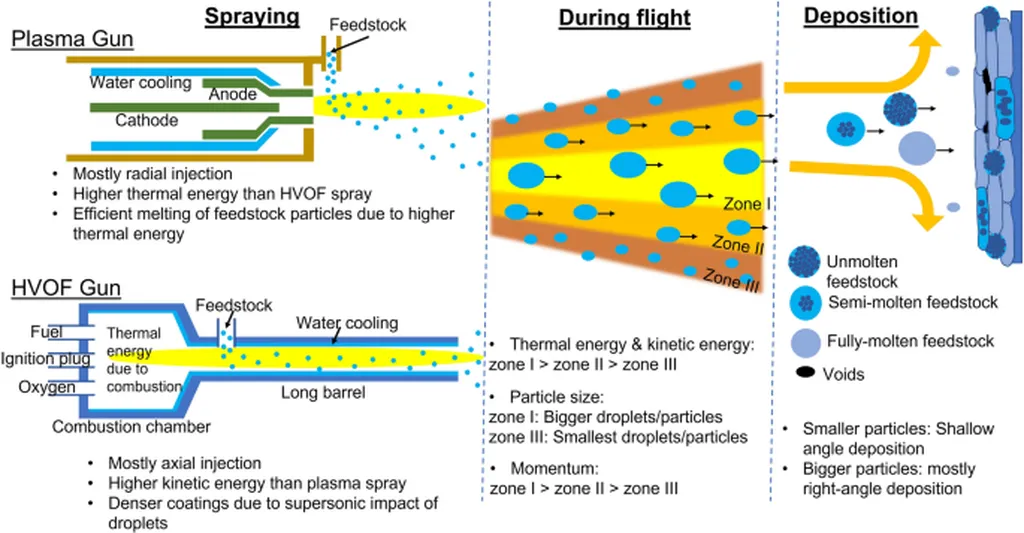

Plasma spraying is a technique used to apply coatings to surfaces, enhancing their resistance to wear, corrosion, and high temperatures. This is particularly valuable in the energy sector, where components often face extreme conditions. Kubaszek and his team have been experimenting with different plasma spraying parameters to optimize the coating’s properties.

Their research, published in the journal ‘Advances in Mechanical and Materials Engineering’ (or ‘Postępy w Budowie Maszyn i Materiałach’ in Polish), involved varying the current intensity and hydrogen flow during the atmospheric plasma spraying (APS) process. They found that increasing the current intensity resulted in thicker coatings, while reducing the hydrogen content led to lower porosity.

“The main type of porosity observed was interlamellar porosity,” Kubaszek explained. “The coatings consisted of two main phases; a matrix rich in cobalt, chromium, nickel, and tungsten, and a ceramic phase composed of zirconium, yttrium, and oxygen (YSZ).”

The implications of this research are significant for the energy sector. By optimizing the plasma spraying parameters, it may be possible to create more durable and efficient coatings for components used in power generation, such as gas turbines and boilers. This could lead to longer component lifespans, reduced maintenance costs, and improved overall efficiency.

Moreover, the research could pave the way for the development of new coating materials and techniques, further enhancing the performance and reliability of energy sector components. As Kubaszek noted, “The post-coating microstructure had a characteristic lamellar structure consisting of overlapping flattened layers with some pore and oxide content.”

This research is a testament to the power of materials science and engineering in driving innovation in the energy sector. As we strive towards a more sustainable and efficient energy future, the work of researchers like Kubaszek will be crucial in overcoming the technical challenges that lie ahead.