In the relentless battle against corrosion, particularly in the harsh marine environment, researchers have made a significant stride forward. Zhenhua Chu, from the Department of Mechanical Engineering at Shanghai Ocean University, has led a study that could potentially revolutionize the energy sector’s approach to protecting infrastructure from corrosive elements. The research, published in *Corrosion Communications* (translated from Chinese as *Corrosion Letters*), focuses on the development of nano TiO2/La2O3 composite coatings that boast impressive corrosion resistance and toughness.

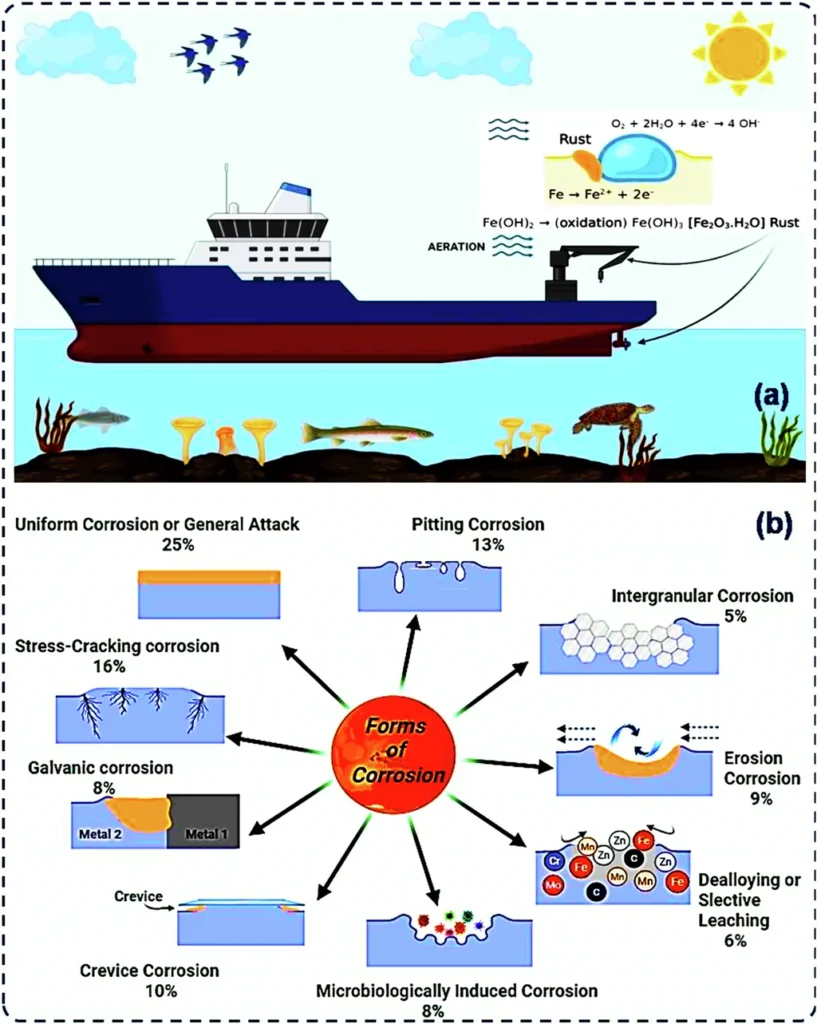

Corrosion is a silent but voracious predator, particularly in the energy sector where infrastructure is often exposed to harsh marine environments. The cost of corrosion is staggering, with estimates suggesting it gobbles up around 3-4% of a country’s GDP annually. In the energy sector, this translates to billions of dollars in lost revenue and maintenance costs. The need for robust, long-lasting protective coatings is therefore not just a technical challenge, but a significant economic imperative.

Chu and his team have tackled this challenge head-on, developing a novel nano composite coating that significantly outperforms traditional micro-size TiO2 ceramic coatings. “The nano composite coatings exhibited an 83.75% decrease in corrosion rate in artificial seawater and a 69.57% decrease in Sulfate-Reducing Bacteria (SRB) solution,” Chu explained. These are not just incremental improvements; they are game-changing reductions in corrosion rates.

The team’s investigation into the corrosion process using Electrochemical Impedance Spectroscopy (EIS) over 31 days revealed that the nano coatings remained stable in both seawater and SRB solution. Moreover, the biofilms that formed on the surface of the composite coating in the SRB solution actually enhanced the corrosion resistance. This is a fascinating finding, as it suggests that the coating can actually improve its own protective capabilities over time.

The implications for the energy sector are profound. Offshore platforms, pipelines, and other infrastructure exposed to marine environments could benefit greatly from these advanced coatings. Reduced maintenance costs, extended infrastructure lifespan, and improved safety are just a few of the potential benefits. As the world continues to push towards renewable energy sources, the need for robust, corrosion-resistant infrastructure will only grow. This research could therefore play a pivotal role in shaping the future of the energy sector.

The study also opens up new avenues for research into the use of nano composite coatings in other challenging environments. The team’s findings suggest that these coatings could be tailored to provide enhanced protection in a wide range of corrosive conditions. This could have significant implications for industries beyond energy, including chemical processing, water treatment, and even aerospace.

In the words of Chu, “This research is just the beginning. We have shown that nano composite coatings can provide exceptional corrosion resistance, but there is still much to explore.” As the world continues to grapple with the challenges of corrosion, this research offers a beacon of hope, a potential path forward in the ongoing battle against this pervasive and costly problem. The publication of these findings in *Corrosion Communications* marks an important milestone, but the journey is far from over. The future of corrosion resistance is here, and it is nano-sized.