In the quest to enhance vehicle safety and energy efficiency, a groundbreaking study led by Ayşegül Akdoğan Eker from Yıldız Technical University has shed new light on the critical role of bumper beams in passenger cars. Published in the *Van Yüzüncü Yıl Üniversitesi Mühendislik Fakültesi Dergisi* (translated to *Engineering Faculty Journal of Van Yüzüncü Yıl University*), the research delves into the optimization of materials and design to improve crashworthiness and energy absorption during frontal collisions.

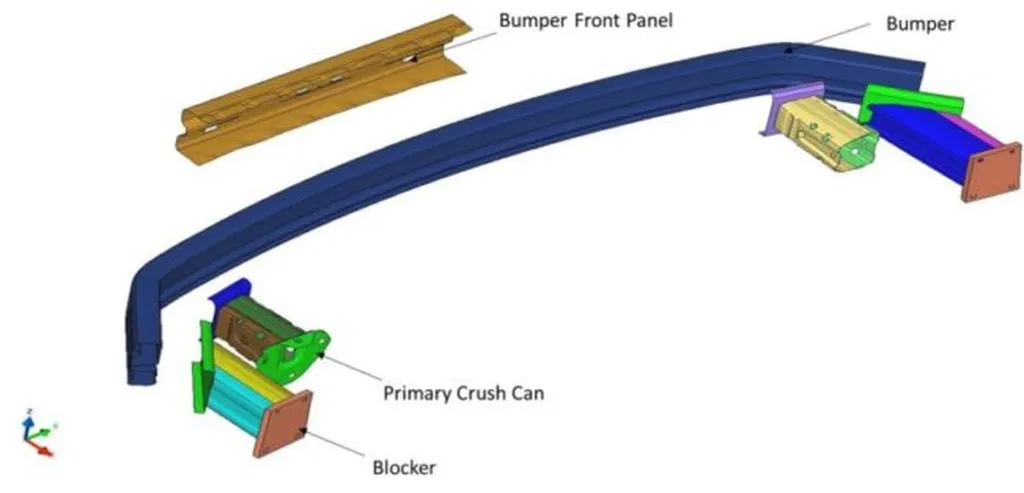

Frontal accidents are among the most common types of vehicle incidents, making the bumper beam a pivotal component in safeguarding the vehicle’s critical systems, including the radiator, cooling system, and engine. “The bumper part must be designed to provide both safety and optimal energy absorption to mitigate impacts effectively,” explained Eker. This study underscores the importance of selecting the right materials and designs to achieve these goals.

The research employed advanced simulation tools to analyze the performance of different materials in crash scenarios. Using Catia V5 for part design and Hypermesh for mesh structure, the team conducted collision simulations with Ansys Ls-Dyna and analyzed the results through Oasys-Suite. The findings revealed that the material labeled MAT1 outperformed MAT2 in terms of resistance to deformation and impact energy absorption. “The force-moment-time graphs, deformation, and stress data obtained from the simulations provided valuable insights into the material’s behavior under impact,” noted Eker.

The implications of this research are significant for the automotive industry, particularly in the energy sector. By optimizing bumper beam materials, manufacturers can enhance vehicle safety while reducing the energy required for transportation and consumption. This not only improves fuel efficiency but also contributes to sustainability efforts.

As the industry continues to evolve, the findings from this study could pave the way for innovative designs and materials that prioritize safety and energy efficiency. “This research highlights the potential for advancements in bumper beam technology, which could have a profound impact on the future of vehicle design and manufacturing,” Eker added.

In an era where safety and sustainability are paramount, this study offers a compelling roadmap for the automotive industry to navigate the challenges ahead. By leveraging cutting-edge technology and innovative materials, manufacturers can create vehicles that are not only safer but also more energy-efficient, ultimately benefiting both consumers and the environment.