In the heart of South Africa, researchers are unlocking new possibilities for advanced materials that could revolutionize the energy sector. Keletso Lebesana, a physicist from the Tshwane University of Technology and the Tandetron Laboratory at iThemba LABS, has been delving into the intriguing world of bimetallic thin films and their interaction with femtosecond lasers. His recent study, published in the journal “Materials Research Express” (which translates to “Expressions of Material Research”), is shedding light on how these ultra-short laser pulses can precisely modify the structure and surface of bimetallic thin films, opening doors to innovative applications in nanotechnology and energy storage.

The research focuses on tin/titanium (Sn/Ti) bimetallic thin films, which are deposited on silicon dioxide/silicon substrates using a technique called molecular beam epitaxy. These films are then exposed to femtosecond laser irradiation, with pulses lasting a mere 300 femtoseconds—that’s a quadrillionth of a second. “The laser’s ultra-short pulses allow us to deposit energy into the material so quickly that the system doesn’t have time to reach equilibrium,” explains Lebesana. “This non-isothermal heating process leads to unique structural changes and surface patterns that we can harness for various applications.”

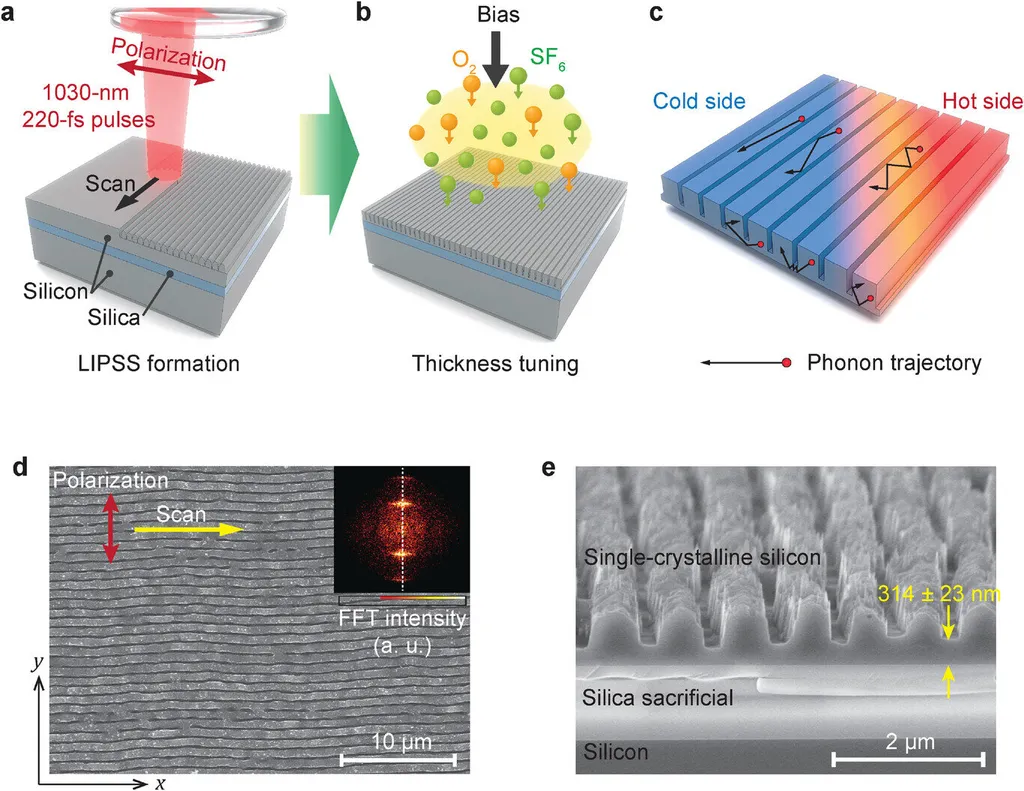

Using advanced characterization techniques like scanning electron microscopy and Rutherford backscattering spectrometry, Lebesana and his team observed the formation of nanostructures such as voids, sphere-like protrusions, and laser-induced periodic surface structures (LIPSS). They also noted elemental diffusion and oxidation, with tin migrating to form oxide layers. The extent of these modifications increased with laser fluence, demonstrating the precise control that femtosecond lasers offer in tailoring material properties.

So, what does this mean for the energy sector? Bimetallic thin films with tailored properties could find applications in advanced energy storage systems, such as next-generation batteries and supercapacitors. By precisely controlling the surface morphology and composition of these films, researchers can enhance their performance, durability, and efficiency. “The ability to modify the microstructure and surface of bimetallic thin films using femtosecond lasers opens up new avenues for designing materials with tailored properties for specific applications,” says Lebesana. “This could lead to significant advancements in energy storage technologies, as well as other fields like catalysis and sensing.”

Moreover, the precise control offered by femtosecond laser processing could enable the fabrication of materials with unique optical, electrical, and mechanical properties. This could pave the way for innovative energy harvesting and conversion devices, such as advanced photovoltaics and thermoelectrics. As the world continues to seek sustainable and efficient energy solutions, research like Lebesana’s is crucial in driving technological advancements and shaping the future of the energy sector.

In the ever-evolving landscape of materials science, Lebesana’s work serves as a testament to the power of precision engineering. By harnessing the unique capabilities of femtosecond lasers, researchers can unlock the full potential of bimetallic thin films and pave the way for groundbreaking developments in energy storage and beyond. As the world grapples with the challenges of climate change and energy demand, these innovations offer a glimmer of hope for a more sustainable and efficient future.