In the ever-evolving world of smart textiles, a groundbreaking study has shed light on a persistent challenge: the sweat resistance of silver-plated yarns. Zhihui Sun, a researcher from the School of Textile Science and Engineering at Wuyi University in Jiangmen, China, has delved into the intricate dance between human sweat and the conductive pathways of these fundamental materials. The findings, published in the Journal of Engineered Fibers and Fabrics (translated as “Journal of Engineered Fibers and Fabrics”), could reshape the future of wearable technology and have significant implications for the energy sector.

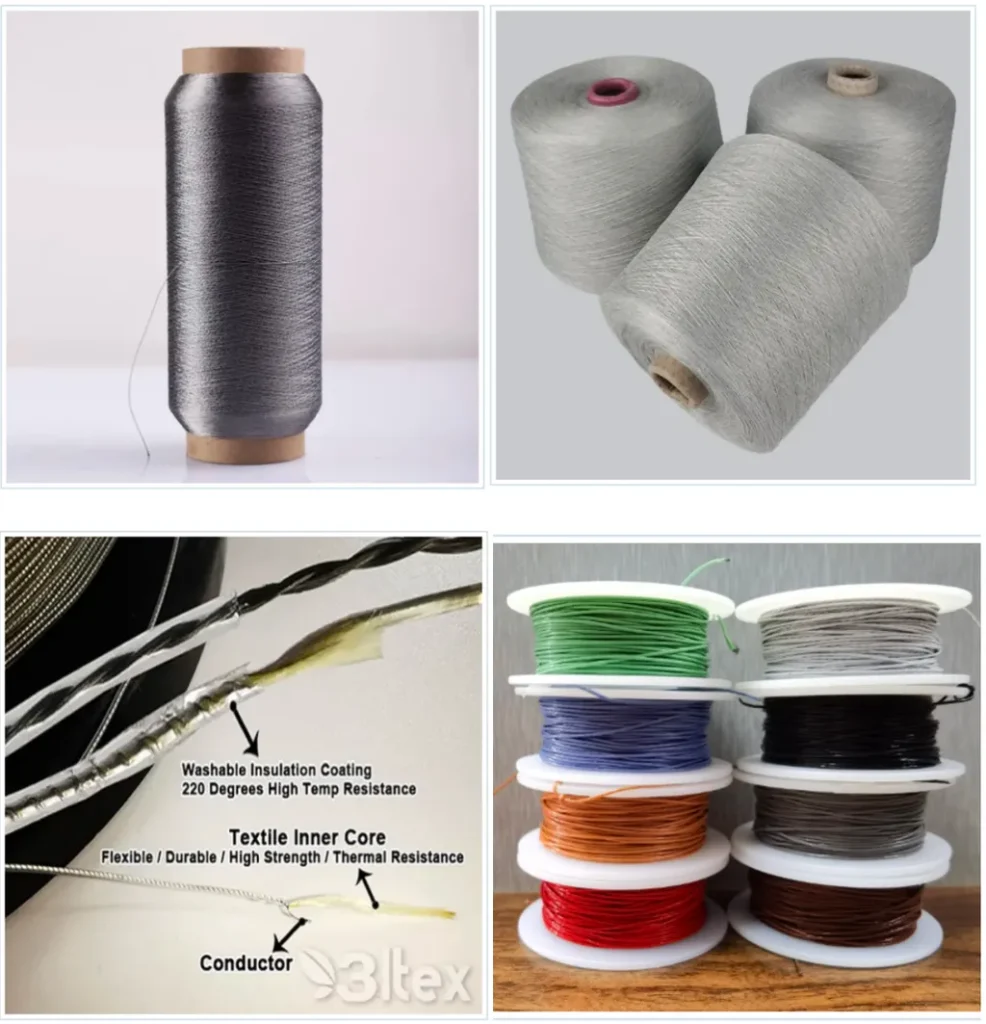

Smart textiles, with their ability to monitor vital signs, track fitness metrics, and even generate energy, have long been touted as the next big thing in wearable tech. However, the harsh reality of daily wear has posed a significant hurdle: human sweat. “The plating on these yarns can be seriously corroded by sweat, degrading their electrical conductivity,” Sun explains. This corrosion not only hampers the functionality of smart textiles but also raises questions about their longevity and reliability.

To tackle this issue, Sun and her team designed a novel set of experimental protocols to simulate the daily wear and tear of silver-plated yarns. They subjected five types of yarns to artificial sweat with varying pH levels, mimicking the acidic and alkaline environments encountered in daily life. The results were eye-opening. After just 10-20 test cycles, almost all samples lost their electrical conductivity, and their mechanical properties also took a hit.

The study revealed that the coating on the yarn surface peeled off after exposure to sweat, interrupting the conductive pathway and leading to a sudden increase in resistance. “The coating reacts electrochemically with chloride ions in sweat, resulting in a sudden increase in resistance,” Sun notes. Moreover, the yarns fared better in acidic sweat than in alkaline sweat, with the silver plating corroding faster in the latter.

The implications of this research are far-reaching, particularly for the energy sector. Smart textiles have the potential to revolutionize energy harvesting and storage, with applications ranging from wearable batteries to solar-powered fabrics. However, the degradation of silver-plated yarns in sweat poses a significant challenge to their commercial viability.

Sun’s findings could pave the way for more robust and durable smart textiles, capable of withstanding the rigors of daily wear. By understanding the electrochemical reactions that occur between sweat and silver-plated yarns, researchers can develop new coatings and treatments to enhance their sweat resistance. This, in turn, could unlock the full potential of smart textiles in the energy sector, leading to innovative applications that harness the power of human motion and the environment.

As the world continues to grapple with the challenges of climate change and energy sustainability, the role of smart textiles in the energy sector cannot be overstated. Sun’s research offers a glimpse into the future of wearable technology, where the boundaries between fashion, functionality, and energy generation blur. By addressing the sweat resistance of silver-plated yarns, we take a step closer to realizing the dream of self-powered, eco-friendly smart textiles that seamlessly integrate into our daily lives.