In the quest for sustainable construction materials, a groundbreaking study led by Maria Binte Mannan from the Department of Civil Engineering has unveiled promising insights into the synergistic effects of waste slag and recycled steel fiber on high-strength concrete (HSC). Published in the journal *Advances in Civil Engineering* (which translates to *Advances in Civil Engineering* in English), this research not only highlights the potential for eco-friendly concrete but also offers a glimpse into the future of construction technology.

The study, which incorporated waste steel fibers and slag—a byproduct of steel manufacturing—into concrete mixes, demonstrated significant improvements in both mechanical and durability properties. “The introduction of 30% slag and 0.75% steel fiber into HSC led to substantial improvements in compressive, tensile, and flexural strengths compared to the reference mix after 90 days,” Mannan explained. This finding is particularly noteworthy for the construction industry, which has long grappled with the challenge of balancing strength and sustainability.

The research also explored the use of machine learning methodologies, specifically artificial neural networks (ANN) and random forest (RF), to predict the strengths of concrete. The RF model showed superior results, with higher R2 values and lower errors compared to ANN. This predictive capability could revolutionize quality control processes in construction, allowing for more accurate and efficient production of high-strength concrete.

From a commercial perspective, the implications are vast. The energy sector, in particular, stands to benefit from the development of more durable and sustainable construction materials. Buildings and infrastructure that require high-strength concrete, such as power plants and wind turbines, could see extended lifespans and reduced maintenance costs. Additionally, the use of waste materials like slag and recycled steel fibers aligns with the growing demand for circular economy practices, where waste is minimized, and resources are kept in use for as long as possible.

The study also revealed that the incorporation of slag improved fresh workability, while steel fibers slightly reduced it due to the interlocking effect. This nuanced understanding of material behavior is crucial for optimizing concrete mixes and ensuring they meet the specific needs of different construction projects.

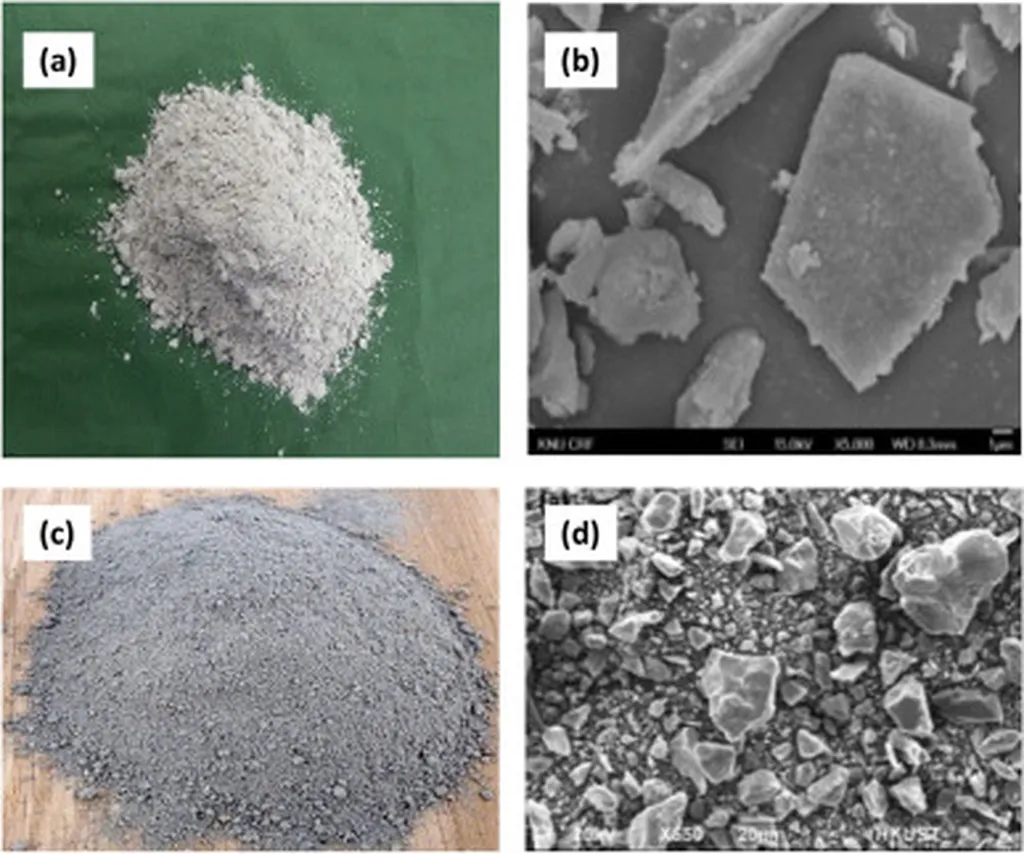

Looking ahead, this research could pave the way for further innovations in the field of sustainable construction. As Maria Binte Mannan noted, “The SEM analysis of slag-based concrete mixes revealed a denser and more homogeneous microstructure with reduced porosity, which correlates with the observed improvements in compressive strength, tensile strength, and durability performance.” This deeper understanding of material properties at the microscopic level could lead to the development of even more advanced and eco-friendly construction materials.

In conclusion, the study by Maria Binte Mannan and her team represents a significant step forward in the quest for sustainable and high-performance construction materials. By leveraging waste materials and advanced predictive modeling, the research offers a blueprint for the future of the construction industry, one that is both environmentally responsible and commercially viable. As the world continues to grapple with the challenges of climate change and resource depletion, such innovations will be crucial in shaping a more sustainable future.