In the quest for more efficient energy systems, a team of researchers led by Kong Weixue from an undisclosed institution has made a significant stride in the field of heat transfer technology. Their study, published in *Zhileng xuebao* (translated to *Acta Armamentarii* or *Journal of Armament*), focuses on the thermal performance of pulsating heat pipes (PHPs), a critical component in various energy applications. The research introduces a novel approach to enhancing the performance of PHPs by incorporating a surfactant solution, cetyltrimethylammonium bromide (CTAB), and employs response surface methodology (RSM) to optimize operating conditions.

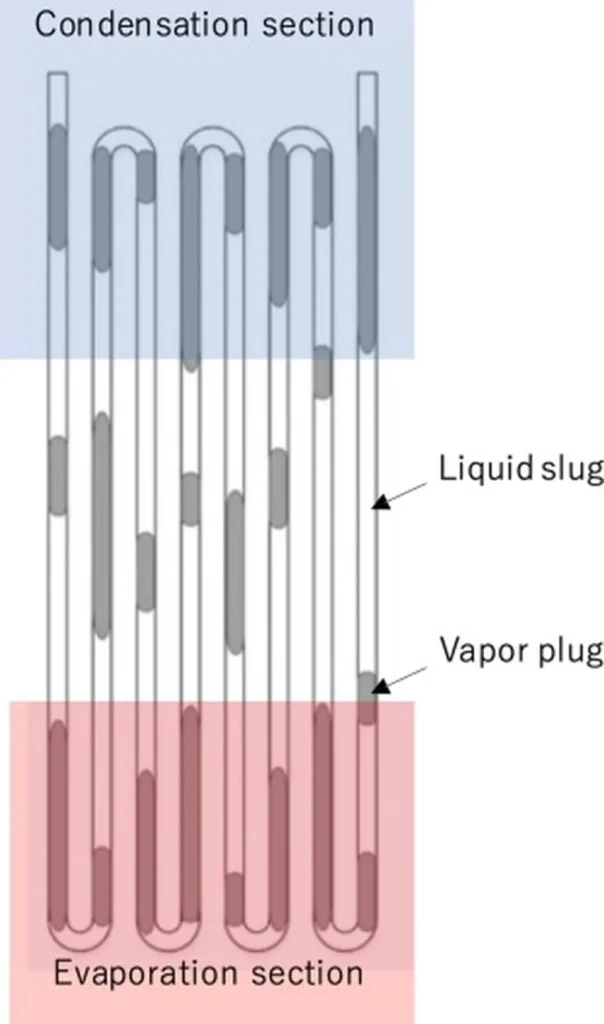

Pulsating heat pipes are highly effective in transferring heat due to their unique design, which allows for the rapid movement of liquid and vapor phases. However, their performance can be significantly influenced by factors such as heating power, filling ratio, and the concentration of additives. Kong Weixue and his team set out to understand these influences more deeply.

“We found that the addition of CTAB can significantly reduce the surface tension of the solution, promoting better boiling heat exchange within the PHP,” explained Kong Weixue. This improvement in heat transfer is crucial for applications ranging from electronics cooling to industrial processes, where efficient heat management can lead to substantial energy savings.

The researchers conducted a series of experiments, varying the heating power (Q), filling ratio (α), and CTAB concentration (ω) to evaluate their impact on the PHP’s thermal performance. Their findings revealed that the optimal concentration of CTAB (around 0.145%) at a moderate filling ratio (50%) could effectively enhance the PHP’s operation, reduce thermal resistance, and alter temperature fluctuation characteristics at lower powers.

“The heating power had the greatest influence on the PHP’s performance, followed by the filling ratio, while the concentration of CTAB had the least impact,” noted Kong Weixue. “Interestingly, the interaction between heating power and filling ratio was the most significant, whereas the interaction between filling ratio and concentration was not significant.”

The study also predicted the minimum thermal resistance of the PHP to be approximately 0.32 ℃/W, indicating a relatively wide optimal operating condition area. This finding is particularly beneficial for practical applications, as it suggests that PHPs can maintain a low overall thermal resistance under various operating conditions.

The implications of this research are far-reaching for the energy sector. By optimizing the performance of PHPs, industries can achieve more efficient heat management, leading to reduced energy consumption and lower operational costs. This is especially relevant in sectors such as electronics manufacturing, where heat dissipation is a critical challenge.

As the world continues to seek sustainable and energy-efficient solutions, the work of Kong Weixue and his team offers a promising avenue for advancements in heat transfer technology. Their findings not only enhance our understanding of PHPs but also pave the way for future developments in energy-efficient systems.

In the words of Kong Weixue, “This research provides a solid foundation for the practical application and performance optimization of PHPs in engineering.” With the insights gained from this study, the energy sector can look forward to more efficient and cost-effective heat management solutions, ultimately contributing to a more sustainable future.