In the world of high-performance sports, every fraction of a second counts. Now, researchers are turning their attention to the very fabric athletes wear, seeking to shave off precious milliseconds by optimizing aerodynamic properties. A recent study published in the journal *Kashf Al-Mawārid* (Discover Materials) by Magdi El Messiry of the Textile Engineering Department at Alexandria University delves into the intricate world of knitted fabrics, revealing how subtle changes in fabric construction can significantly impact air drag.

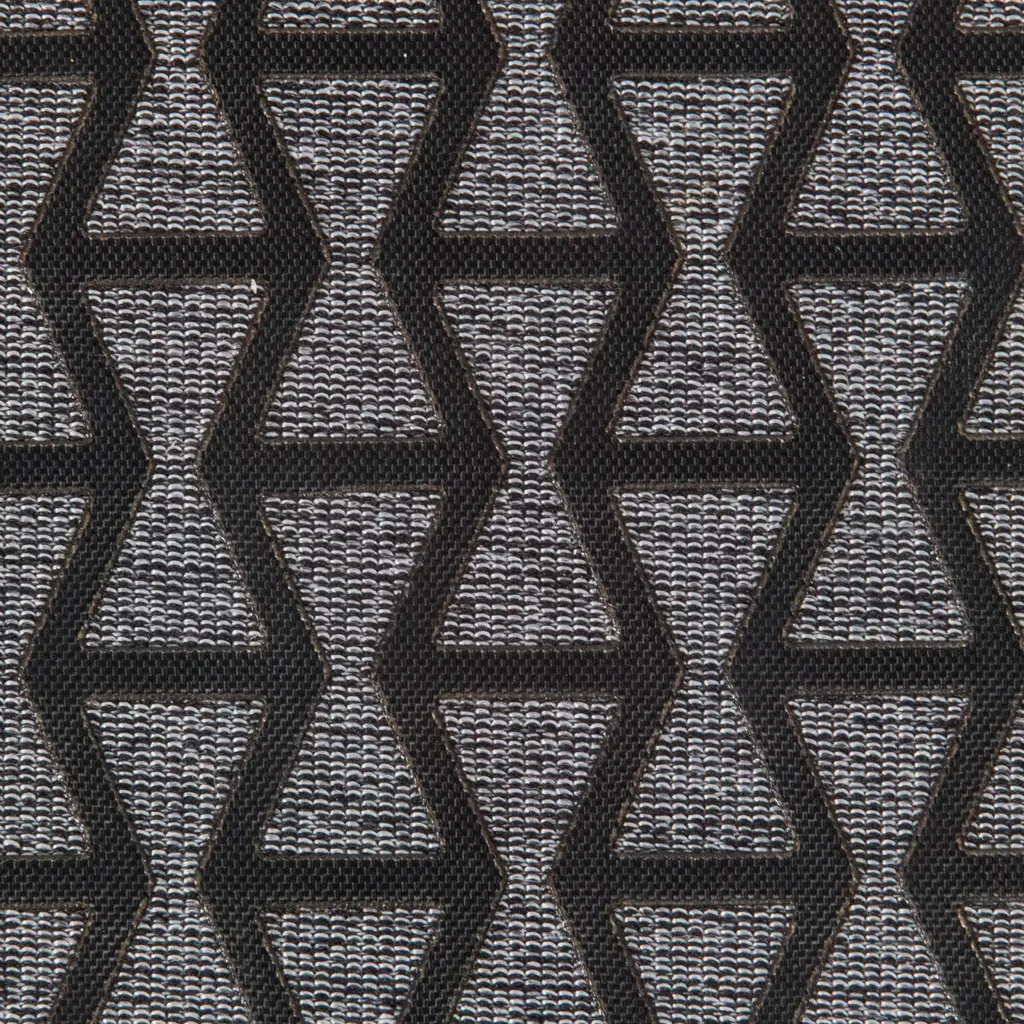

El Messiry and his team focused on single jersey knitted fabrics, a common choice for sports apparel, to understand how different factors influence aerodynamic performance. By varying stitch densities, yarn structures, and loop forms, they created a range of fabric samples to test in a specially designed wind tunnel. The goal? To simulate real-world conditions and measure the drag forces acting on these fabrics.

One of the key findings was the impact of fabric stretch direction. “We found that stretching the fabric in the course direction increased drag force by up to 28% compared to stretching it in the wale direction,” El Messiry explains. This is due to the greater deformation of the loops and the expansion of pore sizes when stretched in the course direction. The study also highlighted the role of slub yarns—those with intentional thick and thin sections—showing that fabrics with these yarns had 15–20% higher drag coefficients at lower Reynolds numbers. This increase is attributed to the added surface roughness and turbulence caused by the slub yarns.

The research didn’t stop at observation; it went a step further to develop empirical equations that can predict drag forces based on factors like Reynolds number, porosity, and surface area. These equations, with an impressive R² value of 0.92, provide a powerful tool for designers and engineers looking to optimize fabric performance.

So, what does this mean for the future of sports fabrics? The findings suggest that to minimize aerodynamic drag, designers should opt for high stitch densities, uniform yarn constructions, and smooth fabric surfaces. This could lead to a new wave of high-performance sportswear designed not just for comfort and flexibility, but also for aerodynamic efficiency.

But the implications extend beyond the sports industry. In the energy sector, where air resistance plays a crucial role in everything from wind turbine blades to the outer shells of high-speed trains, these findings could inspire innovations in material design. Imagine fabrics or coatings that reduce drag, improving efficiency and cutting energy costs. The potential is vast, and the research by El Messiry and his team is just the beginning.

As we look to the future, the intersection of textile engineering and aerodynamics promises to unlock new possibilities. Whether it’s on the track, in the field, or in the energy sector, the fabrics we wear and the materials we use could soon be smarter, more efficient, and more innovative than ever before. And it all starts with a deeper understanding of the forces at play—one stitch, one yarn, and one wind tunnel test at a time.