In the relentless pursuit of enhancing nuclear reactor safety and efficiency, researchers have turned to advanced materials science, yielding promising results that could reshape the energy sector. A recent study published in the journal *Discover Materials* (translated from Russian as *Materials Discovery*) explores the potential of chromium (Cr) and molybdenum (Mo) coatings on zirconium-1% niobium (Zr-1Nb) alloys, aiming to bolster corrosion resistance in nuclear reactor components.

At the heart of this research is Abdelrahman M. Salman, a physicist from the Department of Experimental Physics at the National Research Tomsk Polytechnic University in Russia. Salman and his team investigated the high-temperature oxidation resistance and interdiffusion behavior of Cr/Mo thin-layer coatings on Zr-1Nb alloys, a material commonly used in nuclear fuel claddings. The goal? To develop accident-tolerant fuels that can withstand extreme conditions, thereby enhancing the safety and longevity of nuclear reactors.

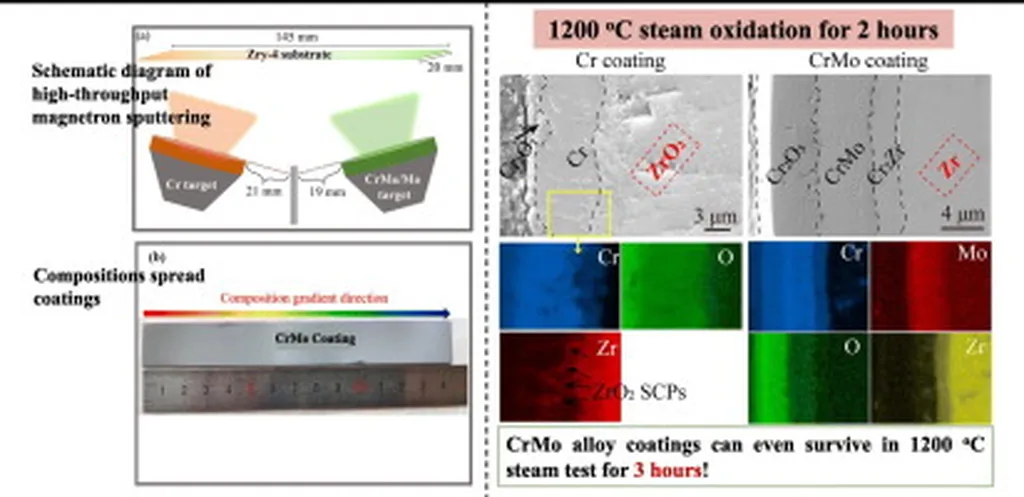

The team employed magnetron sputtering to deposit Mo (3 μm) and Cr (8 μm) coatings onto the Zr-1Nb substrate. When subjected to temperatures of 1100°C, these coatings demonstrated significant improvements in oxidation resistance. “The Cr/Mo coatings showed a remarkable enhancement in protecting the Zr-1Nb alloy from oxidation at high temperatures,” Salman explained. However, the coatings did delaminate after 60 minutes, indicating that further optimization is necessary.

To monitor the stability and performance of these coatings in real-time, the researchers turned to non-destructive testing (NDT) methods. Four probe point (FPP) resistivity and thermal electromotive force (thermoEMF) analysis provided valuable insights into the coating’s behavior under extreme conditions. “These NDT methods offer a powerful tool for advanced diagnostic applications, allowing us to better understand and improve the performance of these coatings,” Salman added.

The implications of this research for the energy sector are substantial. Enhanced corrosion resistance in nuclear fuel claddings could lead to safer, more efficient reactors, reducing the risk of accidents and extending the lifespan of nuclear components. Moreover, the development of accident-tolerant fuels could pave the way for advanced nuclear technologies, contributing to a more sustainable energy future.

As the world grapples with the challenges of climate change and the need for clean energy, innovations in materials science like those explored by Salman and his team offer a beacon of hope. By pushing the boundaries of what’s possible, researchers are not only advancing our understanding of nuclear technology but also shaping the future of the energy sector.

The study, titled “Electrothermal properties and interdiffusion behavior of Cr/Mo coated Zr-1Nb alloy under high temperature for corrosion resistance of nuclear reactor,” was published in *Discover Materials*, highlighting the ongoing efforts to harness the power of advanced materials for a safer, more sustainable world.