In the ever-evolving landscape of materials science, a recent retrospective review published in *Functional Diamond* (which translates to *Functional Diamond* in English) is set to reshape our understanding of surface engineering, particularly in the realm of tribology and corrosion protection. The research, led by Chenglong Mou of the State Key Laboratory of Solid Lubrication at the Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, delves into the nuanced world of diamond and diamond-like carbon (DLC) films, offering a comprehensive analysis that could revolutionize industries from aerospace to energy.

Diamond films, known for their exceptional hardness and thermal conductivity, have long been the gold standard in surface engineering. However, their application has been hindered by challenges such as surface roughness and adhesion issues. Mou’s review highlights the advancements in chemical vapor deposition techniques that are overcoming these hurdles, enabling conformal coatings on complex geometries. “Diamond films offer unparalleled performance, but their practical application has been limited,” Mou explains. “Recent advances in synthesis technologies are changing that narrative.”

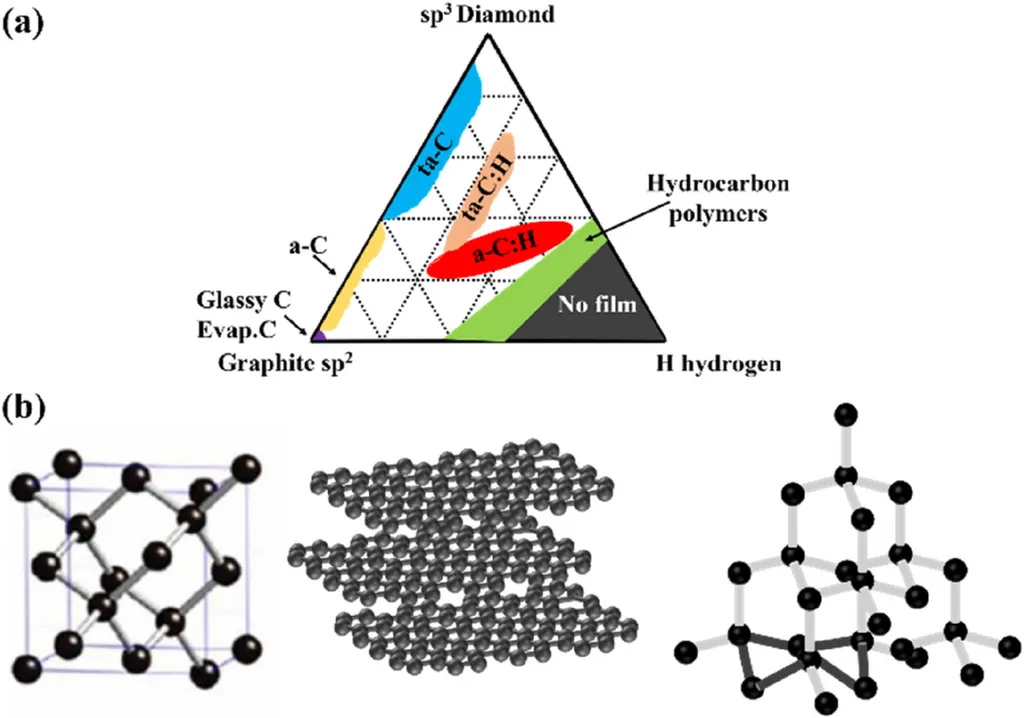

On the other hand, diamond-like carbon (DLC) films provide a more adaptable solution. Composed of sp2/sp³ hybridized carbon, DLC films can be tuned to bridge the gap between diamond’s extreme properties and industrial applicability. The review emphasizes key strategies such as nanocrystalline and multilayer designs, doping, and interface engineering to enhance DLC’s performance. “DLC films are versatile,” Mou notes. “They can be tailored to meet specific industrial needs, making them a valuable tool in our surface engineering arsenal.”

The review also explores the tribological and corrosion-resistant properties of these materials. For DLC, tribological enhancement is achieved through graphitization, C-σ bond passivation, and tribochemistry, while corrosion resistance is improved through densification and multilayer architectures. Diamond films, with their inherent sp³-network corrosion resistance, offer a robust solution for extreme environments.

The implications for the energy sector are profound. In an industry where equipment durability and efficiency are paramount, the advancements in diamond and DLC films could lead to significant cost savings and performance improvements. From offshore wind turbines to deep-sea drilling equipment, the potential applications are vast.

As we look to the future, Mou’s research underscores the need for a unified framework that integrates both diamond and DLC films. “By understanding the complementary roles of these materials, we can push the boundaries of what’s possible in surface engineering,” Mou says. This retrospective review not only highlights the progress made but also sets the stage for future innovations, emphasizing the importance of linking material fundamentals to industrial needs.

In a field where every micron counts, this research is a beacon of progress, illuminating the path forward for the energy sector and beyond. As published in *Functional Diamond*, this work is a testament to the power of materials science in shaping our technological future.