In the realm of power metrology, where precision and reliability are paramount, a groundbreaking method is set to revolutionize environmental monitoring and recognition. Zuo Wang, a researcher at the State Grid Heilongjiang Marketing Service Center in Harbin, China, has introduced a novel approach that combines digital twin technology with an improved Swin Transformer model. This innovation, detailed in a recent study published in *The Journal of Engineering* (translated from Chinese as *机械工程学报*), promises to enhance the reliability and visualization of monitoring systems in power metrology laboratories, with significant implications for the energy sector.

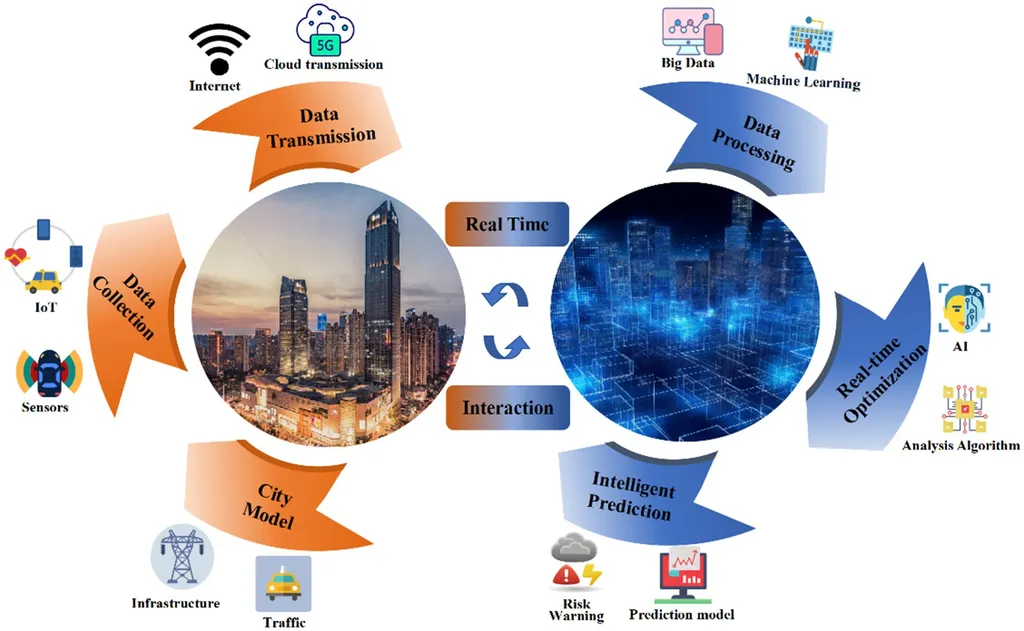

The traditional methods of monitoring power metrology laboratories often fall short in terms of reliability and visualization. Wang’s research addresses these challenges head-on by proposing a smart architecture that leverages digital twin technology. This architecture achieves comprehensive perception of the laboratory environment through the interaction between physical entities and virtual platforms. “By creating a digital twin of the laboratory, we can achieve a more accurate and real-time monitoring system,” Wang explains. “This interaction between the physical and virtual worlds allows for a more holistic understanding of the laboratory’s environment.”

A key component of this innovative method is the integration of a large kernel block module into the Swin Transformer model. This enhancement significantly improves the representation ability between cross-modal feature information, enabling more accurate analysis of laboratory monitoring data. The improved Swin Transformer model is deployed in the intelligent layer of the laboratory architecture, where it analyzes multi-source information to make reliable decisions. “The improved model allows us to fuse different types of data, providing a more comprehensive and accurate identification of personnel behavior and metrology device status,” Wang notes.

The results of this research are impressive. In a virtual smart power metrology laboratory scenario, the method demonstrated an impressive recognition accuracy of 96.74% for sleeping behavior and an average recognition accuracy of 91.74% for metrology device status. These findings highlight the potential of this method to significantly enhance the reliability and efficiency of power metrology laboratories.

The commercial impacts of this research are substantial. In the energy sector, where precision and reliability are crucial, this method can lead to more accurate monitoring and maintenance of metrology devices, reducing downtime and improving overall efficiency. “This technology can be a game-changer for the energy sector,” Wang suggests. “By providing more reliable monitoring and recognition, we can ensure the safety and efficiency of power metrology laboratories, ultimately benefiting the entire energy industry.”

Moreover, this research opens up new avenues for future developments in the field. The integration of digital twin technology and improved machine learning models can pave the way for smarter, more efficient monitoring systems across various industries. As Wang points out, “This is just the beginning. The potential applications of this technology are vast, and we are excited to explore them further.”

In conclusion, Zuo Wang’s research represents a significant advancement in the field of power metrology. By combining digital twin technology with an improved Swin Transformer model, this method offers a more reliable and visual approach to environmental monitoring and recognition. The implications for the energy sector are profound, promising enhanced efficiency and safety in power metrology laboratories. As the industry continues to evolve, this research provides a solid foundation for future innovations, shaping the way we monitor and maintain critical infrastructure.