In the relentless pursuit of enhancing engine efficiency and durability, researchers have turned to advanced materials that can withstand extreme temperatures. A recent breakthrough in ceramic materials science, published in the journal *Cailiao gongcheng* (which translates to *Materials Engineering*), offers a promising solution for high-temperature applications in the energy sector. The study, led by Dr. ZHOU Shaoshuai from the Jiangxi Provincial Engineering Research Center for Surface Technology of Aeronautical Materials at Nanchang Hangkong University, introduces a novel high-entropy rare earth zirconate ceramic material that could revolutionize thermal barrier coatings.

Thermal barrier coatings (TBCs) are crucial for protecting engine components from extreme heat, thereby improving efficiency and longevity. Traditional materials, such as yttria-stabilized zirconia (YSZ), have limitations in terms of thermal conductivity and maximum operating temperature. Dr. ZHOU and his team aimed to address these challenges by designing a high-entropy ceramic material that leverages the unique properties of multiple rare earth elements.

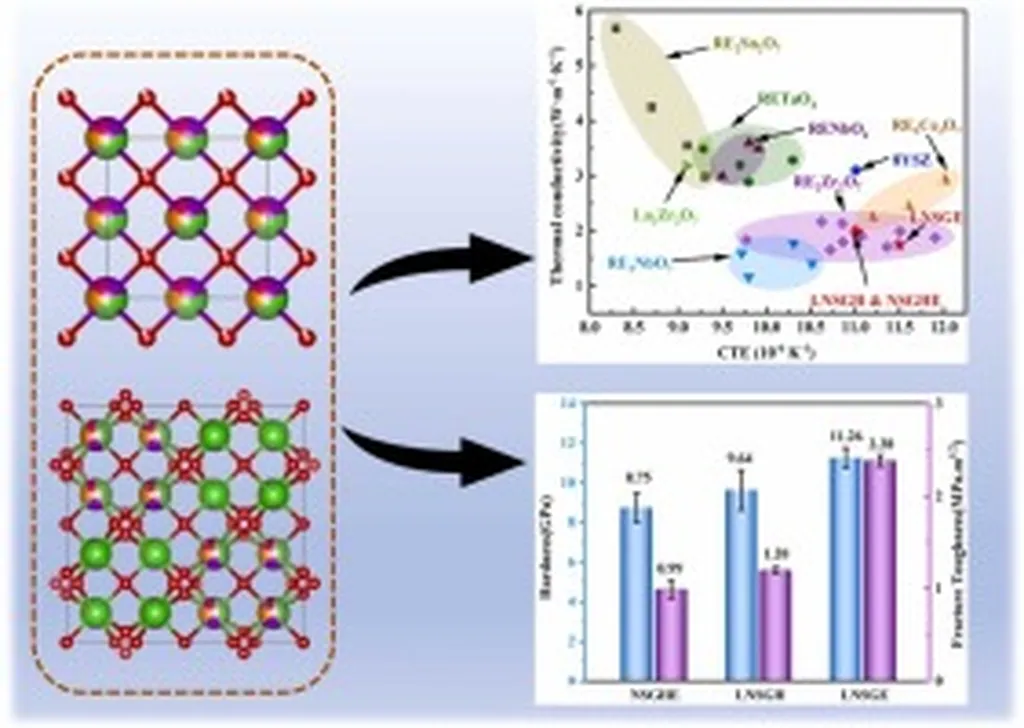

The researchers employed a multi-element rare earth doping modification strategy to create a ceramic material with the formula (Sm0.2Gd0.2Eu0.2Lu0.2Dy0.2)2Zr2O7. This approach capitalizes on the concept of high entropy, where the introduction of multiple elements in equal proportions leads to enhanced stability and improved performance. “By incorporating five different rare earth elements, we aimed to create a material with superior thermal and structural properties,” explained Dr. ZHOU.

The synthesis process involved solid-phase synthesis, resulting in a ceramic material with a defect fluorite structure and a dense, defect-free microstructure. The material demonstrated remarkable phase stability and resistance to grain growth, even after sintering at 1400°C. Notably, the thermal conductivity of the material was measured at 1.781 W·m-1·K-1 at 1000°C and 2.056 W·m-1·K-1 at 1200°C, significantly lower than that of conventional rare earth zirconate and YSZ materials.

The implications of this research are substantial for the energy sector. High-entropy ceramics like the one developed by Dr. ZHOU’s team could enable the development of more efficient and durable engines, particularly in aerospace and power generation applications. “This material has the potential to extend the service life of engine components and improve overall system efficiency,” said Dr. ZHOU.

The study not only advances our understanding of high-entropy ceramics but also paves the way for innovative solutions in thermal management. As the energy sector continues to push the boundaries of temperature and efficiency, materials like (Sm0.2Gd0.2Eu0.2Lu0.2Dy0.2)2Zr2O7 could play a pivotal role in shaping the future of high-temperature technologies. With further research and development, these materials may soon become the cornerstone of next-generation thermal barrier coatings, driving progress in energy efficiency and sustainability.