In a significant stride towards advancing aviation technology, researchers have successfully demonstrated the potential of laser-arc hybrid welding for high-strength aluminum alloys. The study, led by XU Fei from the AVIC Manufacturing Technology Institute in Beijing, focuses on the 7050-T7451 aluminum alloy, a material widely used in the aerospace industry due to its exceptional strength and lightweight properties.

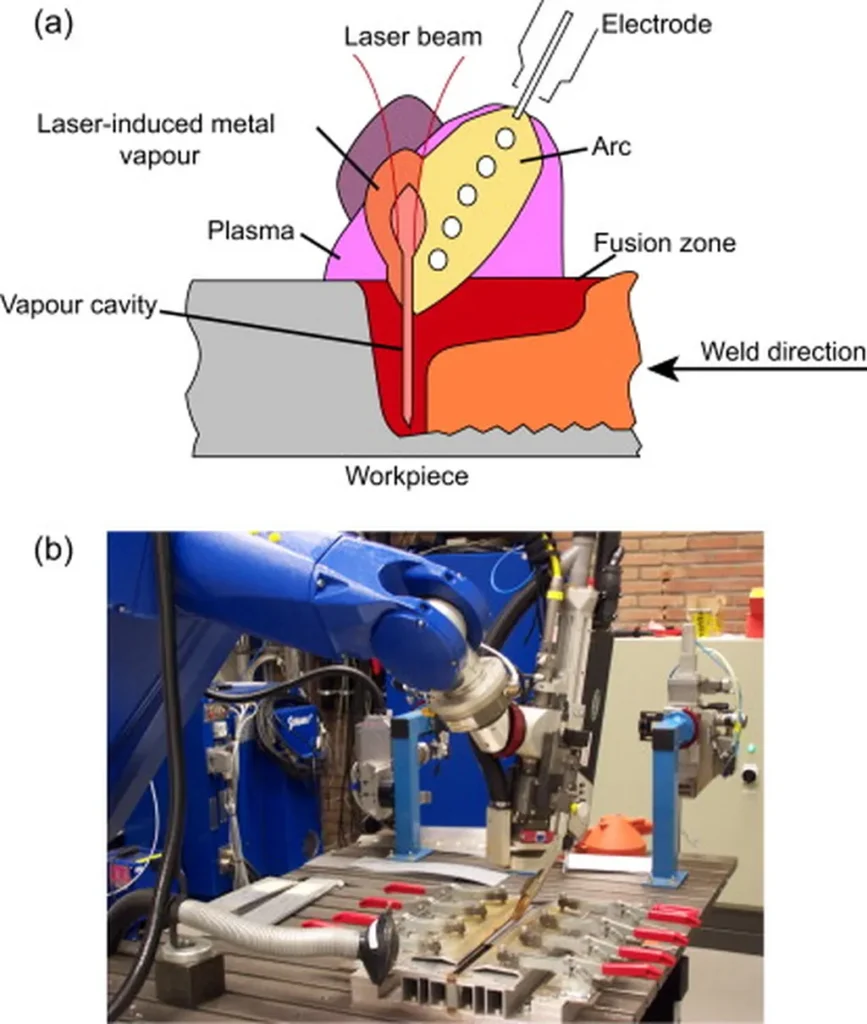

The research, published in *Cailiao gongcheng* (which translates to *Materials Engineering*), explores the microstructure and mechanical properties of 7050-T7451 aluminum alloy joints created using laser-melt inert-gas (MIG) hybrid welding. This innovative welding technique combines the precision of laser welding with the efficiency of MIG welding, offering a promising solution for joining high-strength aluminum alloys.

“By optimizing the welding parameters, we were able to achieve a well-formed weld seam with minimal defects,” XU Fei explained. The study found that controlling the welding speed at 0.9 meters per minute or below, and maintaining a weld back-width ratio above 0.4, effectively suppressed cracks and porosity defects. This careful balance of parameters is crucial for ensuring the integrity and strength of the weld.

The microstructure of the weld zone revealed a fascinating array of equiaxed grain structures with significant size differences. Near the fusion zone, a fine-grained layer approximately 20-50 micrometers wide was observed, with only a minimal amount of columnar grains forming adjacent to this layer. Notably, no phase transformation or recrystallization occurred in the heat-affected zone, preserving the material’s properties.

The as-welded joint achieved an average tensile strength of approximately 377 MPa, which is about 73% of the base metal strength. This is a substantial improvement over the tensile properties of laser self-fusion welded joints, highlighting the potential of laser-arc hybrid welding for high-strength aluminum alloys.

The implications of this research are far-reaching, particularly for the aviation and energy sectors. As the demand for lightweight and high-strength materials continues to grow, the ability to efficiently and reliably weld high-strength aluminum alloys becomes increasingly important. This study paves the way for further advancements in the application of these materials in the aviation field, potentially leading to more fuel-efficient and environmentally friendly aircraft.

XU Fei’s work not only contributes to the scientific understanding of laser-arc hybrid welding but also opens up new possibilities for commercial applications. As the energy sector seeks to reduce weight and improve efficiency, the insights gained from this research could shape future developments in the field.

In the words of XU Fei, “This research represents a significant step forward in the application of high-strength aluminum alloys in the aviation industry. The potential benefits for the energy sector are equally compelling, and we look forward to exploring these opportunities further.”

As the aviation and energy sectors continue to evolve, the findings from this study could play a pivotal role in driving innovation and improving the performance of high-strength aluminum alloy components. The journey towards more efficient and sustainable technologies is underway, and laser-arc hybrid welding is poised to play a crucial part in this exciting future.