In the quest to enhance the performance of carbon fiber reinforced polymer (CFRP) composites, researchers have turned to an unlikely muse: the humble mussel. A recent study published in *Cailiao gongcheng* (which translates to *Journal of Materials Engineering*) explores the promising potential of dopamine, a molecule inspired by the adhesive properties of mussels, to revolutionize the way we modify CFRP composites. The research, led by SONG Chengkai from the College of Materials Science and Engineering at Beijing University of Technology, delves into the interfacial properties of these composites, a critical factor in their overall performance.

CFRP composites are already renowned for their strength, lightweight nature, and versatility, making them indispensable in industries ranging from aerospace to automotive and energy. However, their full potential is often hindered by suboptimal interfacial properties, which can limit their mechanical and physicochemical performance. Enter dopamine, a molecule that has captured the imagination of scientists due to its ability to form strong, adhesive coatings under water, much like the mussel’s tenacious grip on rocks.

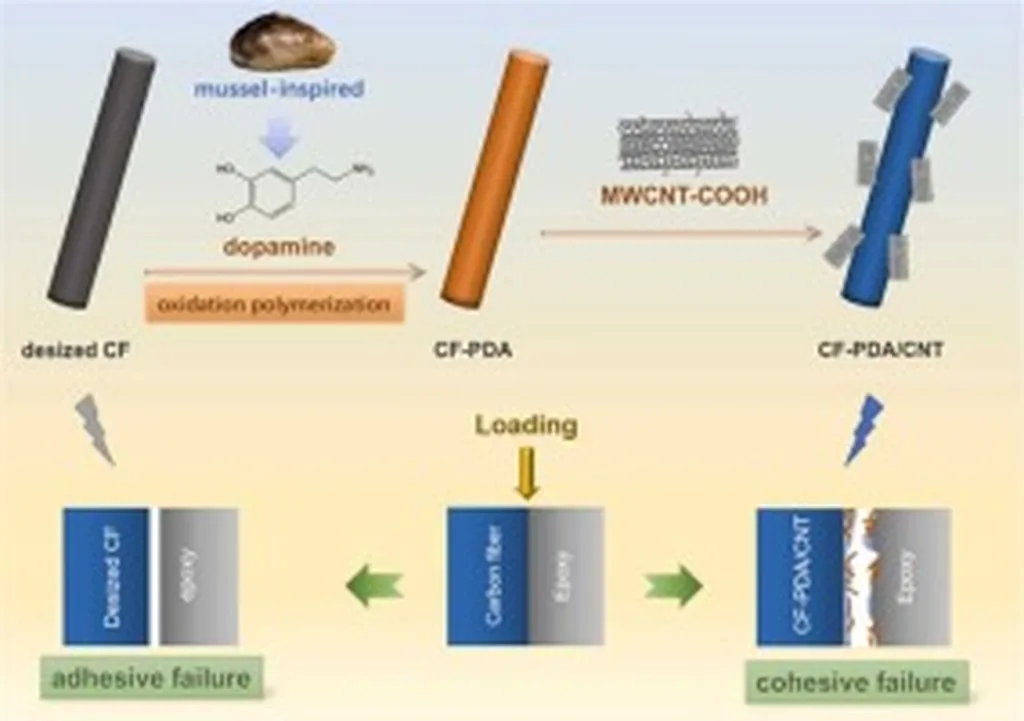

SONG Chengkai and his team have been investigating the use of dopamine to modify the surface of carbon fibers, a process that offers several advantages. “The dopamine-assisted co-deposition modification method is simple, highly efficient, environmentally friendly, and low-cost,” explains SONG. This method involves coating the carbon fibers with a thin layer of polydopamine, which enhances the adhesion between the fibers and the polymer matrix, ultimately improving the composite’s overall performance.

The research highlights the potential of dopamine-modified carbon fibers to significantly enhance the interfacial properties of CFRP composites. This could lead to stronger, more durable materials that are better suited to the demanding environments found in the energy sector, such as wind turbines and oil drilling equipment. “The polymerization deposition mechanism of dopamine-modified carbon fibers still needs systematic in-depth study,” notes SONG, indicating that while the method shows great promise, there is still much to learn about the underlying processes.

The study also points out that the control factors of polymerization deposition rate and coating morphology and structure need to be further clarified. This suggests that future research will focus on optimizing these parameters to maximize the benefits of dopamine modification. As our understanding of these processes deepens, we can expect to see even more innovative applications of dopamine in the field of composite materials.

The implications of this research extend beyond immediate industrial applications. By improving the interfacial properties of CFRP composites, we can develop materials that are not only stronger and more durable but also more sustainable. This aligns with the growing demand for eco-friendly solutions in the energy sector, where the need for high-performance materials is paramount.

In conclusion, the work of SONG Chengkai and his team represents a significant step forward in the field of composite materials. By harnessing the power of dopamine, they have opened up new possibilities for enhancing the performance of CFRP composites, with far-reaching implications for the energy sector and beyond. As we continue to explore the potential of this remarkable molecule, we can look forward to a future where stronger, more durable, and more sustainable materials become the norm.