In the quest to enhance the performance of composite materials, researchers have long grappled with the challenge of voids—tiny air pockets that can significantly impact the mechanical properties of these advanced materials. A recent study published in *Cailiao gongcheng* (translated to *Materials Engineering*) sheds new light on how void content affects the behavior and failure mechanisms of SiC/AZ91D composite materials, offering valuable insights for industries reliant on high-performance materials, particularly the energy sector.

Led by Li Buwei from the School of Aeronautical Manufacturing Engineering at Nanchang Hangkong University in China, the research employs finite element methods and cohesion models to construct a three-dimensional representation of SiC/AZ91D composites with varying void contents. The study meticulously examines how these voids influence the mechanical properties and failure mechanisms of the materials.

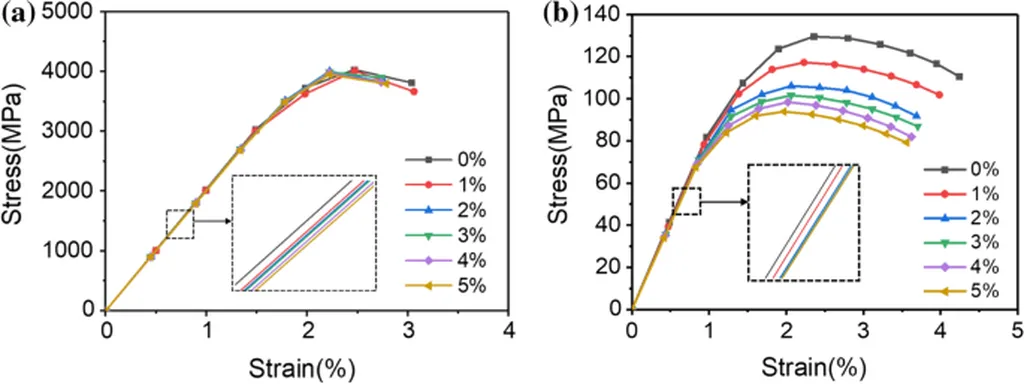

The findings are clear: as void content increases, the mechanical properties of the composite materials decline. “The presence of voids accelerates the appearance and extension of cracks, ultimately compromising the material’s integrity,” Li explains. During the elastic deformation phase, the matrix bears the primary load, and fluctuations in void content have a relatively negligible effect on the stress concentration factor. However, as the material enters the plastic deformation phase, the load gradually shifts from the matrix to the SiC particles. With higher void content, this load transfer diminishes, slowing the growth rate of the stress concentration factor.

For the energy sector, where materials must withstand extreme conditions, these insights are crucial. Composite materials are often used in high-stress applications, such as in wind turbines, aerospace components, and energy storage systems. Understanding how void content affects their performance can lead to more durable and reliable materials, reducing maintenance costs and improving safety.

Li’s research suggests that optimizing void content could enhance the mechanical properties of composite materials, making them more suitable for demanding applications. “By controlling the void content, we can potentially improve the overall performance and longevity of these materials,” Li notes. This could pave the way for more efficient and robust energy solutions, driving innovation in the sector.

As the energy industry continues to evolve, the demand for high-performance materials will only grow. Research like Li’s provides a roadmap for developing materials that can meet these demands, ensuring a more sustainable and efficient future. With the findings published in *Cailiao gongcheng*, the scientific community now has a clearer understanding of how to optimize composite materials for real-world applications, shaping the future of material science and engineering.