In the quest to bolster the corrosion resistance of magnesium alloys, a team of researchers led by WANG Bingjie from the College of Mechanical Engineering at Qinghai University has made significant strides. Their work, published in *Cailiao gongcheng* (which translates to *Materials Engineering*), focuses on the influence of annealing treatment on the microstructure and properties of cold-sprayed Zn-Al alloy coatings. This research could have profound implications for the energy sector, particularly in applications where magnesium alloys are exposed to harsh environments.

Magnesium alloys are prized for their lightweight and high strength-to-weight ratio, making them ideal for various industrial applications, including automotive and aerospace components. However, their susceptibility to corrosion has long been a challenge. The team’s investigation into cold-sprayed Zn-Al composite coatings offers a promising solution. By subjecting these coatings to annealing treatments at different temperatures—200, 250, and 300 degrees Celsius—the researchers aimed to enhance the coatings’ performance.

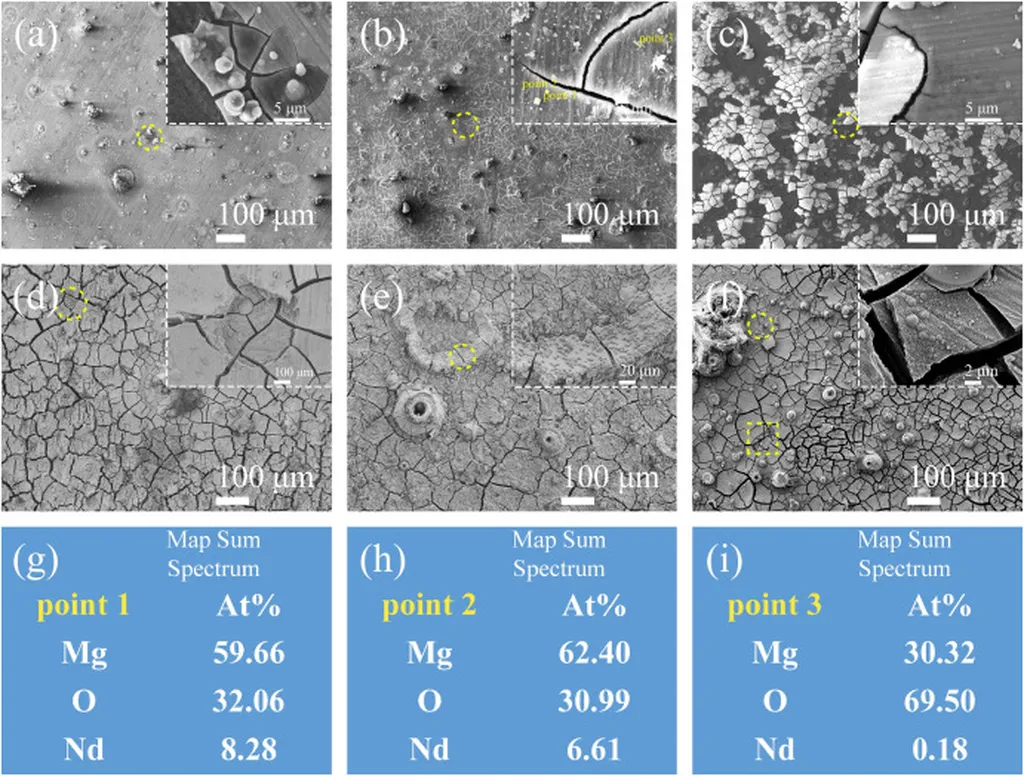

Using advanced analytical techniques such as X-ray diffractometer (XRD), scanning electron microscope (SEM), microhardness tester, electrochemical workstation, and salt spray corrosion test equipment, the team meticulously analyzed the microstructure and properties of the coatings before and after heat treatment. Their findings revealed that annealing treatment significantly improved the coatings’ density and corrosion resistance without causing oxidation or phase transformation.

“After annealing treatment at different temperatures, the coatings became denser, and their corrosion resistance improved,” WANG Bingjie explained. “Interestingly, we observed an annealing hardening phenomenon as the temperature increased. At 250 degrees Celsius, the composite coatings achieved the highest density, with a porosity of just 0.3998%.”

The electrochemical and salt spray tests further confirmed the benefits of annealing. The treated coatings formed a dense corrosion layer, which substantially enhanced their resistance to corrosion. The optimal annealing temperature was found to be 250 degrees Celsius, where the coatings exhibited the best corrosion resistance.

This research not only advances our understanding of cold-sprayed Zn-Al composite coatings but also paves the way for innovative applications in the energy sector. By improving the durability and corrosion resistance of magnesium alloys, these coatings can extend the lifespan of critical components in renewable energy systems, such as wind turbines and solar panels, as well as in traditional energy infrastructure.

As the energy sector continues to evolve, the demand for lightweight, high-performance materials will only grow. The findings from WANG Bingjie’s team offer a glimpse into the future of material science, where advanced coatings and treatments can mitigate longstanding challenges and unlock new possibilities. This work, published in *Cailiao gongcheng*, underscores the importance of continuous research and development in materials engineering, driving progress and innovation in the energy industry.