In the world of advanced manufacturing and electronics, the stress of electroplated copper films is a critical factor that can significantly impact the performance and reliability of components. A recent study published in *Cailiao gongcheng* (translated as *Journal of Materials Engineering*) sheds new light on how substrate materials influence the stress of electroplated copper films, offering valuable insights for industries ranging from semiconductor manufacturing to renewable energy.

The research, led by JIANG Yingyu from the School of Integrated Circuits at Shandong University in Jinan, China, investigates the effects of substrate roughness, crystal type, and coefficient of thermal expansion (CTE) on the stress of electroplated copper films. By utilizing four distinct substrate types—smooth sapphire, rough sapphire, amorphous sintered alumina, and pure copper—JIANG and his team conducted a meticulous experiment to understand the underlying mechanisms.

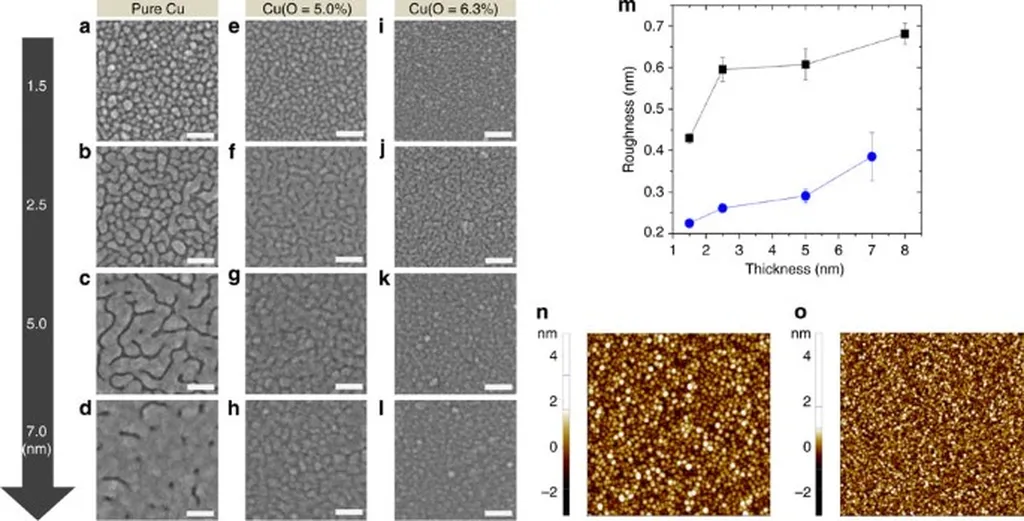

The study involved electroplating copper films onto these substrates and then annealing them. Pre- and post-annealing measurements were taken to assess warp and stress, while electron backscatter diffraction (EBSD) was employed to study the microstructural transformation of the copper films. The results revealed that annealing transforms the copper film stress from compressive to tensile, with stress levels decreasing in the order of sintered alumina, smooth sapphire, rough sapphire, and pure copper substrates.

“Annealing leads to significant grain growth, and the post-annealing copper film stress arises from CTE mismatch and volume shrinkage,” JIANG explained. “By selecting rough single-crystal substrates and materials with CTEs close to that of copper, we can effectively reduce the stress in copper films.”

The findings have profound implications for the energy sector, particularly in the development of advanced energy storage systems and power electronics. Copper films are widely used in these applications due to their excellent conductivity and thermal properties. However, managing stress in these films is crucial for ensuring the longevity and efficiency of components.

“Understanding the stress dynamics in electroplated copper films can help engineers design more robust and reliable systems,” JIANG added. “This research provides a roadmap for selecting the right substrate materials to minimize stress and enhance performance.”

The study’s insights are particularly relevant for the renewable energy industry, where the demand for high-performance, durable components is ever-increasing. By optimizing the substrate materials used in electroplating processes, manufacturers can produce components that are less prone to failure and more efficient in their operation.

As the world continues to transition towards cleaner energy sources, the need for advanced materials and manufacturing techniques becomes ever more critical. This research not only contributes to the scientific understanding of electroplating stress but also paves the way for innovative solutions in the energy sector.

Published in *Cailiao gongcheng*, the study offers a comprehensive analysis of the factors influencing copper film stress, providing a valuable resource for researchers and industry professionals alike. As the field of materials engineering continues to evolve, these findings will undoubtedly shape future developments and drive advancements in technology.