In the pursuit of stronger, more resilient materials for critical applications, researchers have turned their attention to the often-overlooked details—like the shape of a notch. A recent study published in *Cailiao gongcheng* (translated as *Journal of Materials Engineering*) has uncovered how the radius of a V-notch can significantly influence the mechanical properties of TA15 titanium alloy, a material widely used in aerospace, energy, and other high-performance industries.

Led by Cui Wenming from the General Research Institute for Nonferrous Metals in Beijing, the research team conducted a series of tests—tensile, stress-rupture, and fatigue—to evaluate how varying notch radii affect the alloy’s performance. “We wanted to understand how small changes in geometry could lead to big differences in material behavior,” Cui explained. The findings reveal that as the notch radius decreases, the tensile strength and stress-rupture time of the alloy increase, while the proportion of shear-plastic zones in fractures decreases.

The team also employed finite element analysis to map the stress-strain field around the notch, discovering that stress triaxiality—a measure of the stress state—peaks near the notch root before decreasing inward. This peak is where fractures originate, a critical insight for designing components that must withstand extreme conditions. “Understanding this behavior allows us to optimize material performance in real-world applications,” Cui added.

The implications for the energy sector are particularly compelling. TA15 titanium alloy is often used in high-stress environments, such as in turbine blades and other critical components where fatigue and stress-rupture are major concerns. By fine-tuning the notch radius, engineers could extend the lifespan of these components, reducing maintenance costs and improving safety.

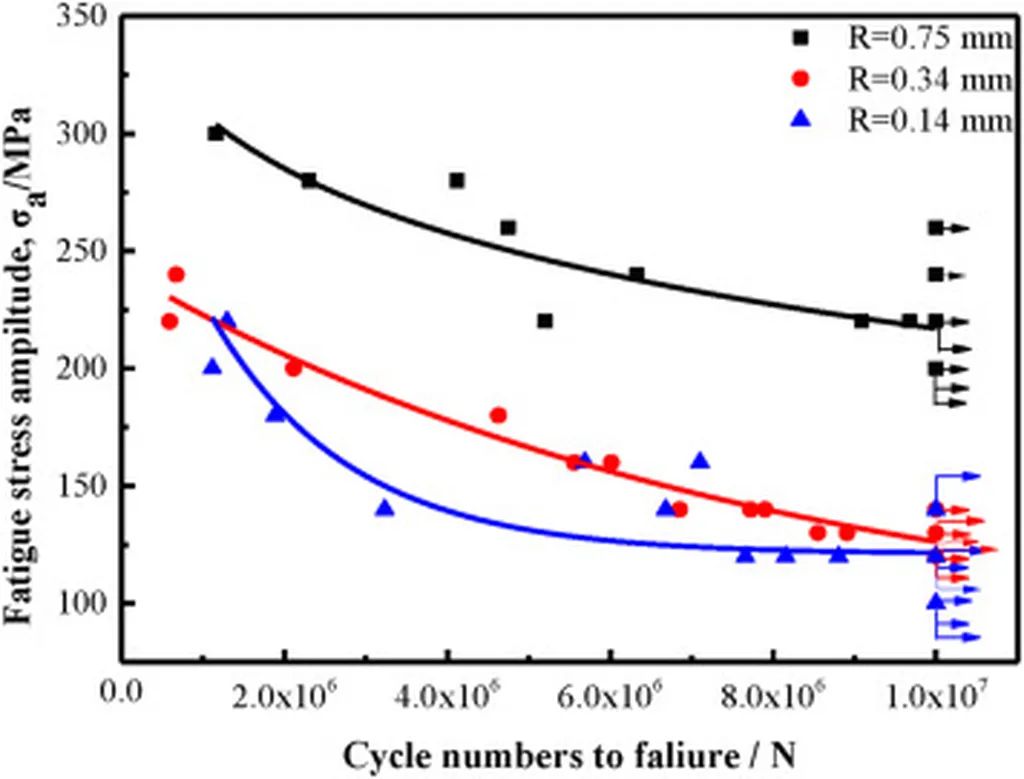

The study also sheds light on how stress redistribution occurs during prolonged stress-rupture tests, leading to a strengthening effect at the notch. Under dynamic loading, the fracture surface of notched specimens showed multi-source crack propagation, with smaller notch radii leading to reduced fatigue life. This suggests that careful consideration of notch design could help mitigate fatigue-related failures in energy infrastructure.

As the energy sector continues to demand materials that can perform under increasingly harsh conditions, this research offers a roadmap for optimizing TA15 titanium alloy for real-world applications. By leveraging these insights, engineers could develop components that are not only stronger but also more reliable, ultimately driving innovation in the energy industry.