In the quest to make alumina ceramics more accessible and efficient to produce, researchers have made a significant stride in reducing the energy-intensive process of sintering. A recent study led by Xiang Yang from the College of Aerospace Science and Engineering at the National University of Defense Technology in Changsha, China, has unveiled a method to lower the sintering temperature of alumina ceramics, potentially revolutionizing the energy sector.

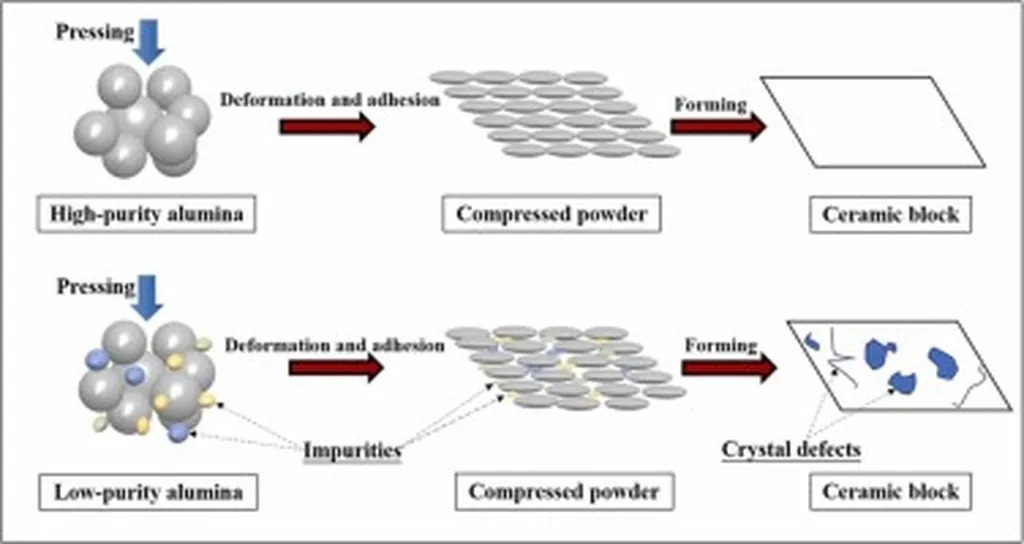

Alumina ceramics, known for their exceptional hardness and resistance to corrosion and high temperatures, are widely used in various industries, including energy. However, their production process has been a bottleneck due to the high temperatures required for sintering, a process that fuses ceramic powders into a solid mass. This high-temperature requirement not only consumes substantial energy but also limits the materials that can be used in the process.

In their study published in *Cailiao gongcheng* (translated to *Materials Engineering*), Xiang and his team explored the use of organic alumina precursors as sintering aids. These precursors, which can be in either solid or liquid phase at room temperature, were added to alumina powder to investigate their effect on the sintering temperature.

The researchers found that both types of precursors significantly reduced the sintering temperature. “We observed that the optimal additive amount of both precursors is 6% within the temperature range of 1200-1400 ℃,” Xiang explained. However, as the temperature increased to 1500 ℃, the optimal additive amounts diverged. The solid-phase precursor required only 2%, while the liquid-phase precursor needed 10%.

This discovery could have profound implications for the energy sector. Lower sintering temperatures mean reduced energy consumption and costs, making alumina ceramics more viable for large-scale applications. Moreover, the ability to fine-tune the sintering process with different precursors opens up new possibilities for customizing ceramic properties for specific uses.

“The potential to tailor the sintering process to different temperatures and precursor types is a game-changer,” said Xiang. “It allows us to optimize the mechanical performance of alumina ceramics for various applications, from energy generation to storage and transmission.”

The study provides a valuable experimental basis for optimizing the low-temperature sintering process and selecting parameters for alumina ceramics. As the energy sector continues to evolve, the efficient preparation of advanced materials like alumina ceramics will be crucial. This research not only advances our understanding of ceramic processing but also paves the way for more sustainable and cost-effective manufacturing practices.

In the broader context, this work highlights the importance of innovative materials science in driving technological progress. As Xiang and his team continue to explore the potential of organic alumina precursors, their findings could shape the future of ceramic manufacturing, offering new solutions to longstanding challenges in the energy sector.