In a groundbreaking development poised to revolutionize the construction industry, researchers have unveiled a novel approach to self-healing concrete that could significantly impact the energy sector. The study, led by Alan Rodrigo Sorce, explores the integration of biomineralizing bacteria into ultra-high-performance concrete (UHPC), offering a sustainable and efficient solution to a longstanding challenge.

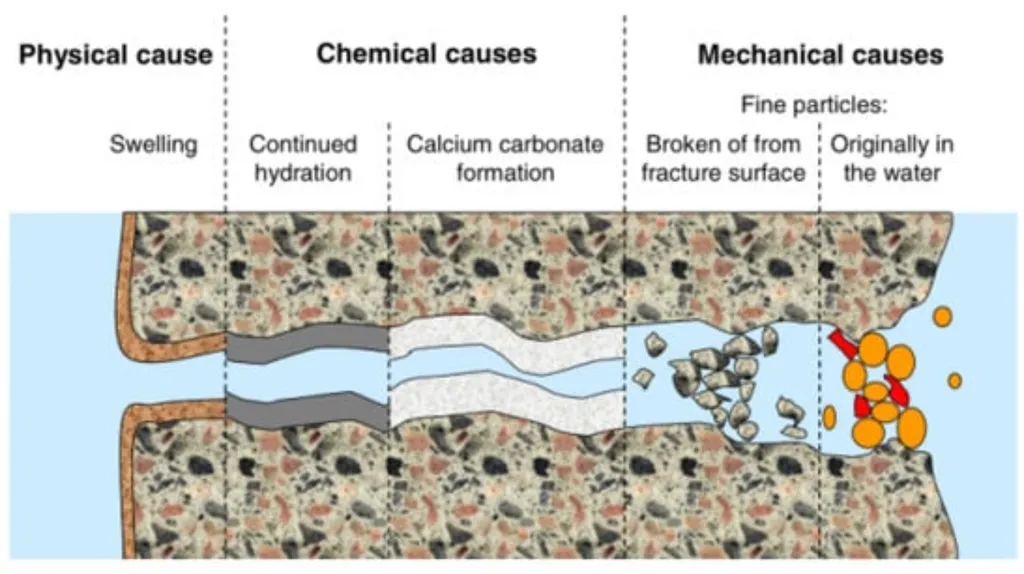

Cracks in concrete structures are a pervasive issue, compromising mechanical strength and exposing the interior to environmental damage. Traditional repair methods often fall short in the long term and can be environmentally harmful. Sorce’s research, published in the Brazilian Journal of Structural and Materials Engineering (Revista IBRACON de Estruturas e Materiais), introduces a promising alternative: self-healing concrete assisted by microorganisms.

The study investigates the addition of sodium alginate capsules containing Lysinibacillus sphaericus, a biomineralizing bacteria, to UHPC. The capsules were added in varying proportions—0.5%, 1.0%, and 1.5%—to the cement mass. The results were striking. “We found that the mechanical properties of the UHPC were not affected by the addition of the capsules,” Sorce explains. “Moreover, there were no statistically significant changes in porosity or water absorption compared to the standard formulation.”

This means that the incorporation of bacterial capsules did not compromise the concrete’s structural integrity or durability. Optical microscopy images confirmed the efficiency of the encapsulation technique and the deposition of calcium carbonate in the cracks, a process known as Microbial Induced Calcium-Carbonate Precipitation (MICP).

The implications for the energy sector are profound. Concrete is a fundamental material in energy infrastructure, from power plants to wind turbines. Self-healing concrete could extend the lifespan of these structures, reducing maintenance costs and minimizing downtime. Additionally, the environmental benefits are substantial. Traditional repair methods often involve toxic components and by-products, contributing to pollution. The bio-concrete approach offers a greener alternative, aligning with the growing demand for sustainable construction practices.

Sorce’s research suggests that the methodology has high potential for the development of self-healing UHPC bio-concretes. This innovation could pave the way for more resilient and sustainable infrastructure, particularly in the energy sector. As the industry continues to seek eco-friendly solutions, the adoption of bio-concrete could become a game-changer, ensuring that our energy infrastructure is not only robust but also environmentally responsible.

In the words of Sorce, “This research opens up new possibilities for the future of construction, offering a sustainable and efficient solution to a longstanding problem.” The journey towards self-healing bio-concretes has just begun, and the potential is immense.