In the quest for sustainable construction practices, a groundbreaking study has emerged that could reshape the way we think about concrete blocks and waste management. Gabriela Bertazzi Pignotti, a leading researcher in the field, has published a study in the journal *Revista IBRACON de Estruturas e Materiais* (translated to *IBRACON Journal of Structures and Materials*), exploring the potential of incorporating cementitious waste into non-structural concrete blocks. This innovative approach not only addresses the pressing issue of waste management but also offers a promising solution for reducing the environmental impact of the construction industry.

The construction sector is a significant contributor to economic growth, but it also generates a substantial amount of waste. Pignotti’s research focuses on the practical and feasible application of cementitious waste from block manufacturing in the production of new blocks. “The aim is to maximize mechanical performance while minimizing the environmental impact caused by the excessive use of non-renewable materials,” Pignotti explains.

The study involved characterizing the constituent materials of concrete blocks, including sand, stone dust, gravel, and waste. Using Alfred’s method and unit weight, Pignotti defined four distinct concrete mixes: a reference mix and mixes containing 0%, 3%, and 5% cementitious waste. The blocks were produced industrially and then evaluated for compressive strength, water absorption, dimensional analysis, and shrinkage.

The results were promising. The compressive strength of the blocks ranged from 5.16 MPa to 5.99 MPa, while water absorption ranged from 6.40% to 7.29%. Notably, the drying shrinkage of the blocks ranged from 0.040% to 0.110%, with the mixes containing waste showing results within and above the normative limit of 0.065%, depending on the dosage. “The incorporation of cementitious waste into concrete blocks for non-structural masonry is feasible at the industrial level without significant reduction in its properties when compared to concrete without incorporation,” Pignotti states.

The best-performing mix was the one with 5% waste incorporation, considering the overall performance across all evaluated properties. This finding has significant implications for the construction industry, particularly in the energy sector, where sustainable practices are increasingly prioritized. By utilizing cementitious waste, construction companies can reduce their environmental footprint while maintaining the quality and performance of their products.

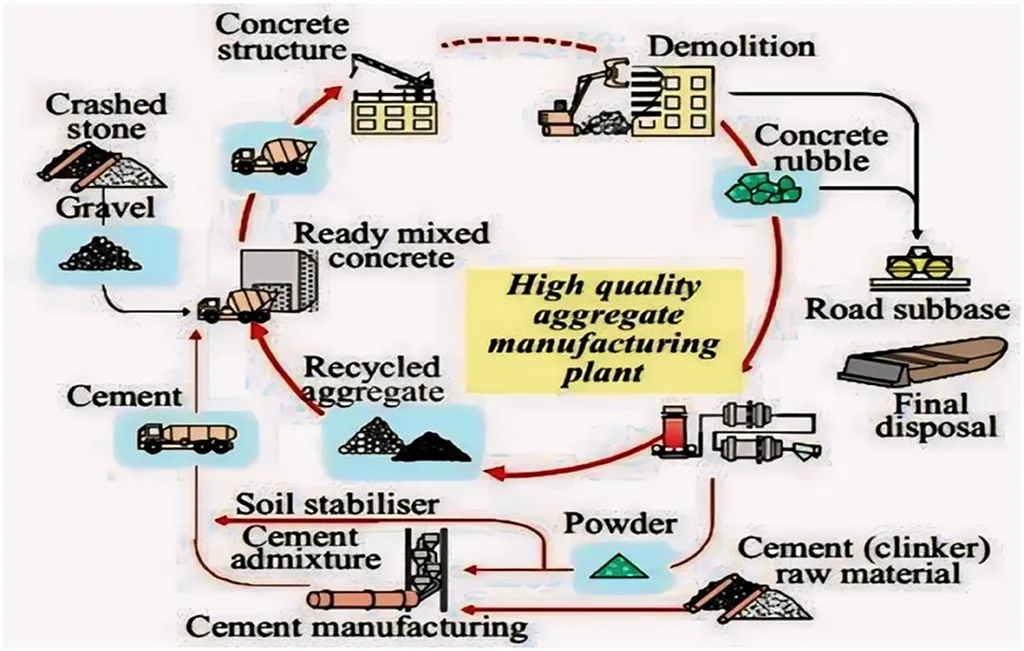

Pignotti’s research not only highlights the potential of recycled aggregates but also underscores the importance of sustainability in the construction industry. As the demand for eco-friendly building materials continues to grow, this study offers a viable solution that could shape future developments in the field. The commercial impacts are substantial, with the potential to reduce waste disposal costs and create new markets for recycled materials.

In conclusion, Pignotti’s study published in *Revista IBRACON de Estruturas e Materiais* provides a compelling case for the incorporation of cementitious waste into concrete blocks. This innovative approach offers a sustainable solution that could revolutionize the construction industry, paving the way for a greener and more efficient future. As the industry continues to evolve, the insights gained from this research will be invaluable in driving forward-thinking practices and technologies.