In the relentless pursuit of pushing boundaries, the construction industry is turning to an unlikely ally: robotics. A recent study led by Ke You from the National Center of Technology Innovation for Digital Construction at Huazhong University of Science and Technology in China, sheds light on the transformative potential of construction robotics in extreme environments, with significant implications for the energy sector.

Extreme environments—whether it’s the harsh landscapes of the Arctic, the depths of the ocean, or the unforgiving heat of deserts—pose immense challenges to human explorers and construction workers. These environments are often unstructured and rapidly changing, making traditional construction methods not only inefficient but also hazardous. Enter construction robotics, a field that integrates digital technology and artificial intelligence to mitigate these risks and enhance operational efficiency.

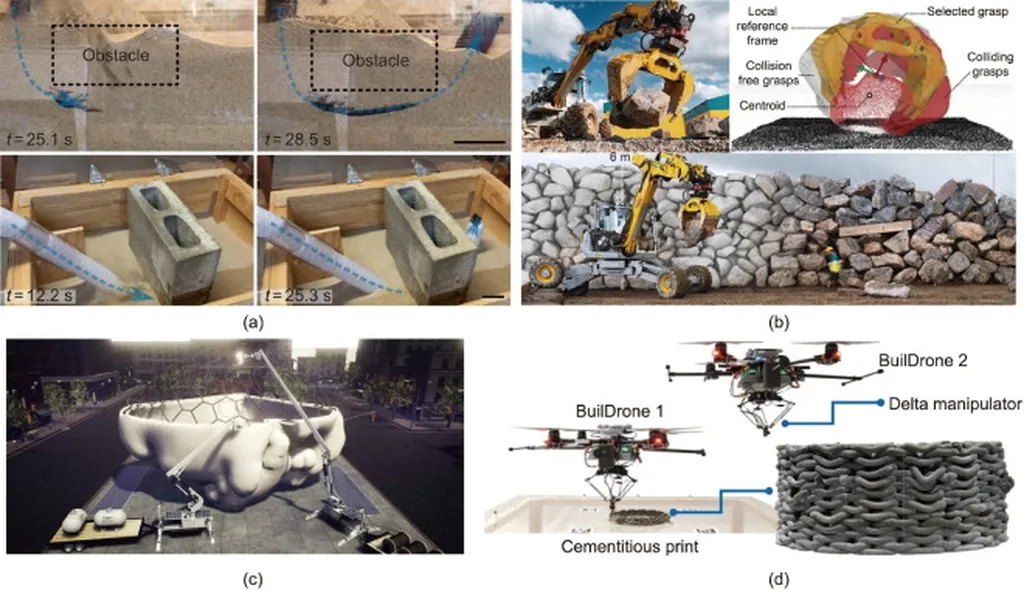

You and his team’s research, published in the journal *Engineering* (translated from Chinese), focuses on four critical areas: mechanism design, perception, planning, and control. Each of these areas presents unique challenges. For instance, designing mechanisms that can adapt to the unpredictable nature of extreme environments is a formidable task. Similarly, accurately perceiving and interpreting these dynamic settings requires advanced sensory technologies and algorithms.

“One of the key challenges we identified is the need for adaptive planning strategies,” You explains. “Traditional planning methods often fail in unstructured environments because they rely on predefined models that don’t account for rapid changes. Our research highlights the necessity for more flexible, adaptive approaches that can respond in real-time to the evolving conditions of extreme environments.”

The implications for the energy sector are profound. Offshore wind farms, deep-sea oil rigs, and remote renewable energy projects all operate in extreme conditions where human labor is both dangerous and costly. Construction robotics can significantly reduce these risks while improving the quality and efficiency of construction. For example, robotic systems equipped with advanced perception capabilities can monitor and maintain energy infrastructure in real-time, predicting potential failures before they occur.

Moreover, the study emphasizes the importance of hybrid control models that combine data-driven approaches with mechanism-based designs. This hybrid approach ensures that robotic systems are not only responsive to immediate environmental changes but also robust enough to handle the physical demands of extreme conditions.

As the energy sector continues to expand into more challenging territories, the role of construction robotics will become increasingly vital. The research conducted by You and his team not only highlights the current gaps in the field but also points towards promising avenues for future exploration. Biomimetic designs inspired by nature, multimodal data fusion for perception, and adaptive planning strategies are just a few of the innovative directions that could shape the future of construction robotics.

In the words of You, “The future of construction robotics lies in our ability to create systems that are not only technologically advanced but also adaptable and resilient. By addressing the challenges we’ve identified, we can unlock new possibilities for construction in extreme environments, ultimately driving progress in the energy sector and beyond.”

As the industry continues to evolve, the integration of robotics into construction practices will undoubtedly play a pivotal role in shaping a safer, more efficient, and sustainable future.