In the quest for sustainable and durable construction materials, a recent study published in the Brazilian Journal of Structural and Material Engineering (Revista IBRACON de Estruturas e Materiais) has shed light on the promising potential of geopolymers. Researchers, led by Giovanny Antonio Ramos, have investigated the durability of geopolymer pastes incorporating metakaolin (MK) and porcelain polishing residue (PPR) when exposed to magnesium sulfate attacks.

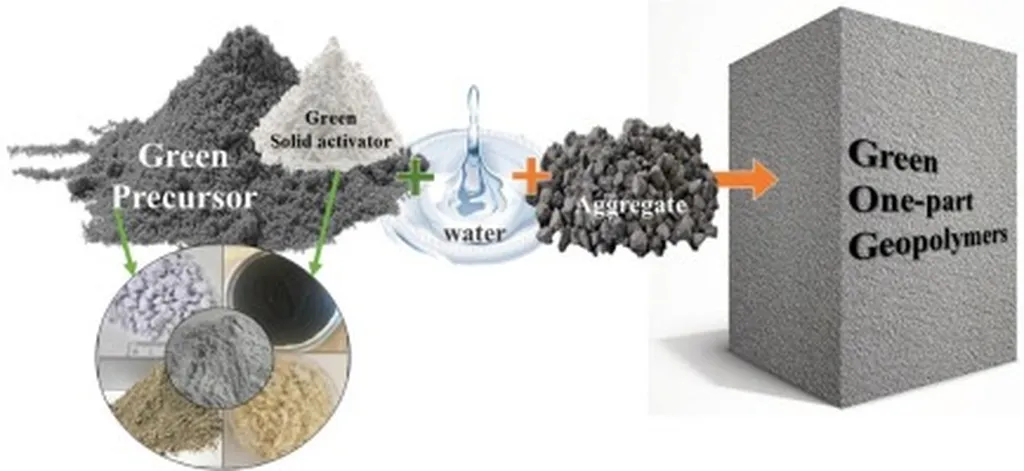

Geopolymers, known for their ability to incorporate various residual materials, are emerging as a viable alternative to traditional binders. However, their long-term durability, particularly in aggressive environments, has been a subject of ongoing research. Ramos and his team sought to address this gap by producing geopolymer pastes with MK partially replaced by PPR at levels ranging from 0 to 45% by weight. The performance of these pastes was then evaluated under magnesium sulfate attack over a 90-day period.

The results were intriguing. The researchers observed increases in compressive strength of up to 23% after exposure to magnesium sulfate, a trend consistent across all levels of MK replacement by PPR. This unexpected enhancement in strength is likely attributed to the absence of expansive products commonly linked to sulfate attacks, such as ettringite and gypsum, as confirmed by X-ray diffraction analysis.

Moreover, the study’s SEM-EDS analysis suggested that magnesium ions (Mg2+) were incorporated into the matrix, bonding with the aluminosilicate gel and enhancing its performance. “This incorporation of magnesium ions into the geopolymer matrix is a novel finding,” Ramos noted. “It not only improves the material’s strength but also opens up new avenues for utilizing geopolymers in sulfate-aggressive environments.”

The implications of this research are significant for the construction industry, particularly in sectors where durability and sustainability are paramount. The energy sector, for instance, could benefit greatly from materials that can withstand harsh conditions while reducing environmental impact. “Our findings contribute to the advancement and sustainability of the construction industry,” Ramos explained. “By using residual materials like PPR, we are not only enhancing the performance of geopolymers but also promoting a circular economy.”

The study’s results highlight the potential of MK and PPR-based geopolymeric materials for use in environments where sulfate attacks are a concern. This could lead to more durable and sustainable infrastructure, reducing maintenance costs and environmental impact. As the construction industry continues to seek innovative solutions, geopolymers are poised to play a crucial role in shaping the future of sustainable construction.

The research, published in the Brazilian Journal of Structural and Material Engineering, underscores the importance of ongoing investigations into the durability and performance of geopolymer materials. As Ramos and his team continue to explore the potential of these materials, the construction industry stands to benefit from more resilient and environmentally friendly solutions.