In the realm of precision manufacturing, predicting milling forces with accuracy is akin to forecasting the weather—it’s complex, but getting it right can save time, money, and resources. A recent study led by Kunpeng Zhu from the Lab of Precision Manufacturing at the Hefei Institutes of Physical Science, Chinese Academy of Sciences, and the School of Machinery and Automation at Wuhan University of Science and Technology, has introduced a novel approach to this challenge. Published in the journal *Engineering* (translated from its Chinese title), the research presents a physics-guided deep network model that promises to revolutionize milling dynamics prediction, with significant implications for industries like energy that rely on high-precision machining.

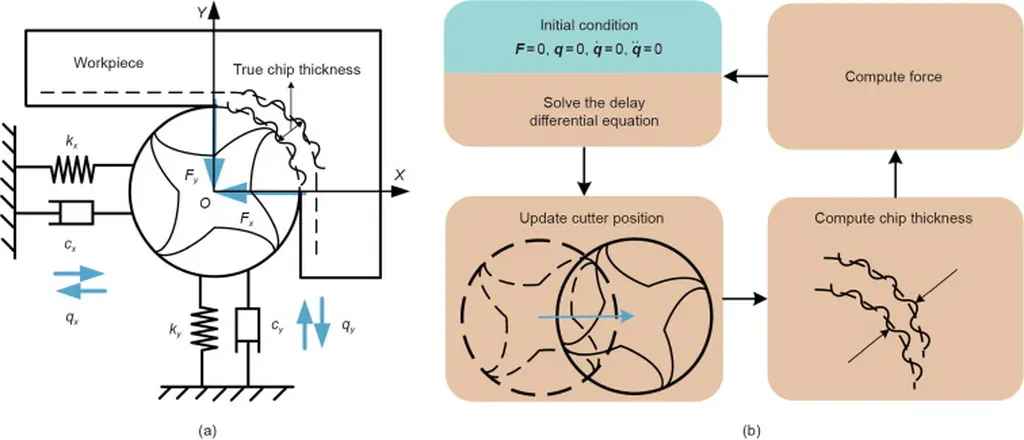

Traditional milling force models have long been hampered by their oversimplified conditions and incomplete data, leading to inaccuracies. On the other hand, purely data-driven models, while powerful, often lack interpretability and struggle to generalize to real-world applications. Zhu and his team aimed to bridge this gap by integrating physical principles with deep learning.

“The key innovation here is the fusion of physics-based models with deep learning,” Zhu explains. “By using a milling dynamics model to pre-train our deep network and then fine-tuning it with experimental data, we’ve significantly improved both the accuracy and the interpretability of our predictions.”

The team’s approach is particularly noteworthy for its incorporation of the vibration equation into the loss function, a move that enhances the model’s interpretability by grounding it in physical constraints. This hybrid method not only improves prediction accuracy but also makes the model more transparent and easier to trust in practical applications.

In a series of milling experiments, the model demonstrated its effectiveness, achieving an impressive average error rate of just 2.6705%. Compared to purely data-driven models, the physics-guided network showed a 24.4367% increase in prediction accuracy. These results suggest that the model could be a game-changer for industries that require high-precision machining, such as energy and aerospace.

The commercial impacts of this research are substantial. In the energy sector, for instance, where components often need to be machined to exacting standards, accurate milling force prediction can lead to significant cost savings and improved product quality. By reducing the trial-and-error involved in machining processes, manufacturers can minimize material waste and optimize tool life, ultimately leading to more efficient and sustainable operations.

Looking ahead, the success of this physics-guided deep network model opens up exciting possibilities for future research. As Zhu notes, “This approach could be extended to other manufacturing processes, such as turning, grinding, and additive manufacturing. The potential for improving prediction accuracy and interpretability across various applications is immense.”

The study’s findings, published in *Engineering* (机械工程), mark a significant step forward in the integration of physics and deep learning. As industries continue to seek more efficient and precise manufacturing methods, the insights gained from this research could pave the way for a new era of smart, data-driven manufacturing.