In a significant stride towards sustainable construction materials, researchers have developed a method to enhance the mechanical properties of biodegradable biocomposites, potentially revolutionizing industries seeking eco-friendly solutions. The study, led by Amer Tounsi from the Laboratory of Mathematical Physics, Quantum Modelling, and Mechanical Design at the Preparatory Engineering Institute of Nabeul, University of Carthage, Tunisia, focuses on optimizing polylactic acid (PLA) biocomposites reinforced with untreated date palm fiber fabrics (DPFs).

The research, published in ‘Materials Research Express’ (which translates to ‘Journal of Materials Research Express’), employs a multi-objective optimization strategy that combines the NSGA-II genetic algorithm and Response Surface Methodology (RSM). This approach aims to minimize property scatter and maximize performance, reducing experimental costs through an ANOVA sensitivity analysis.

Tounsi and his team investigated key manufacturing parameters such as heating temperature, fiber percentage, pressure holding time, and pressure force to optimize strain, maximum stress, and Young’s modulus while minimizing density. The results are promising: for 5% DPFs, the Young’s modulus, maximum stress, and strain increased by 23%, 3%, and 227%, respectively, with only a 1.5% rise in density. Dispersion reduced by 54% for Young’s modulus and 57% for maximum stress. For 10% DPFs, maximum stress and strain rose by 24% and 121%, with a 3% decrease in density and unchanged Young’s modulus. Dispersion dropped by 158% for Young’s modulus and 95% for maximum stress.

“Our framework not only enhances the mechanical properties of biocomposites but also reduces material waste, energy use, and trial-and-error manufacturing,” Tounsi explained. “This advancement is crucial for high-tech industries aiming for sustainability.”

The experimental validation confirmed the proximity of the results to the simulated optimal solutions, with errors of 13.33% or less for most properties. Scanning Electron Microscopy (SEM) imaging revealed strong fiber-matrix adhesion without any pretreatment, further simplifying the manufacturing process.

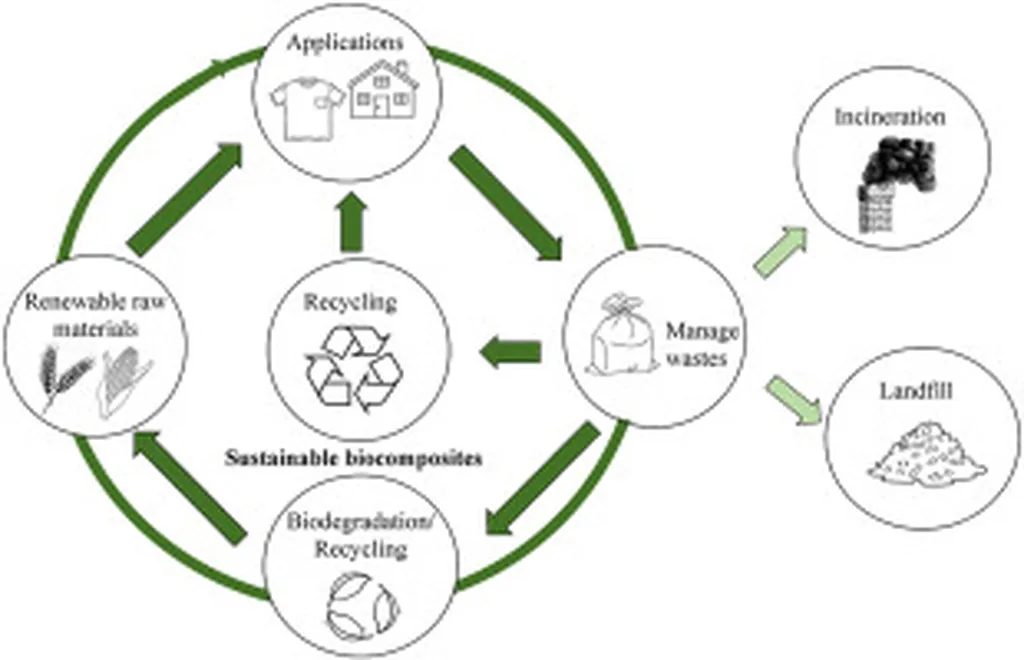

The implications for the energy sector are substantial. As industries increasingly seek sustainable and biodegradable materials, this research provides a robust framework for designing high-performance biocomposites. The optimization strategy can be applied to various bio-based materials, reducing reliance on non-renewable resources and minimizing environmental impact.

“This research is a game-changer for the construction and energy sectors,” said a senior industry analyst. “The ability to optimize biocomposite properties while reducing waste and energy consumption aligns perfectly with the goals of a circular economy.”

The study’s findings pave the way for future developments in sustainable material design, offering a blueprint for industries to achieve high-performance, eco-friendly solutions. As the world moves towards greener technologies, this research provides a crucial step forward in the quest for sustainable innovation.