In the heart of Russia, at the Ufa State Petroleum Technological University, a significant stride is being made in the realm of industrial robotics. Vasily V. Lukyanov, a leading researcher in the field, has published a comprehensive review in the journal ‘Нанотехнологии в строительстве’ (Nanotechnologies in Construction), shedding light on the latest trends in industrial robotic manipulators and their profound impact on the energy sector.

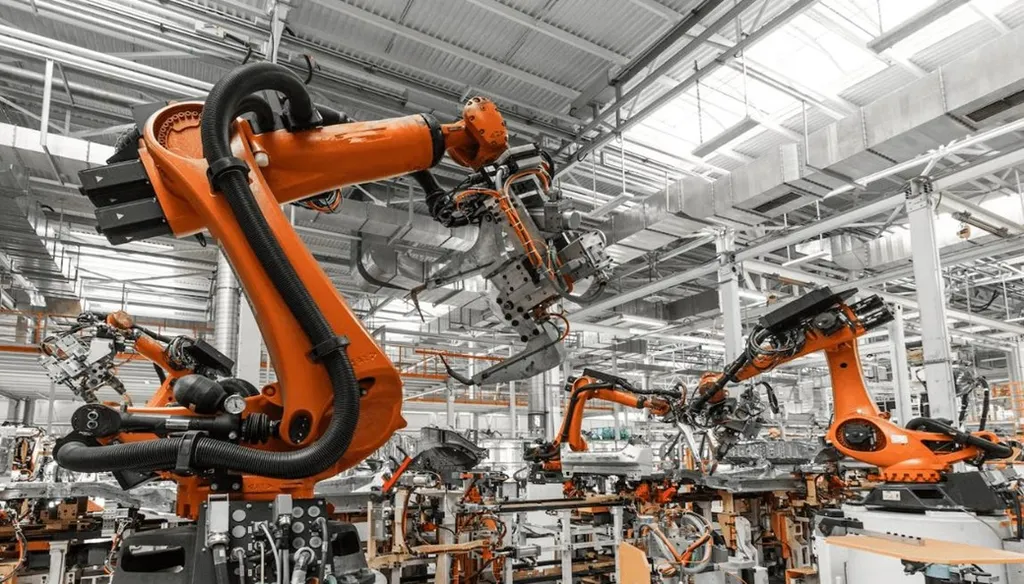

Industrial robotic manipulators are no longer the stuff of science fiction; they are becoming an integral part of modern enterprises, particularly in the energy sector. These versatile machines can perform complex operations with high precision and speed, even in extreme conditions. Lukyanov’s research delves into the design features, control methods, and manufacturing technologies that make these manipulators so effective.

The review presents a classification of robotic manipulators based on their design features, number of degrees of freedom, and drive types. It analyzes their application areas and market trends, pointing to a steady growth in the industrial robotic manipulator market. This growth is driven by the transformation of production processes in line with the concept of Industry 4.0.

Lukyanov explains, “The integration of machine vision and artificial intelligence into manipulator control systems is becoming a key trend in robotics. Such solutions enable rapid response to changing operating conditions and the prevention of potential accidents.”

The research examines the structural components of robotic manipulators: the mechanical part, the drive, and the control system. It also presents an overview of modern materials used in the production of manipulators. Lukyanov proposes a method for enhancing the performance properties of structural components through the use of materials with a nanocrystalline structure.

The implications for the energy sector are significant. As the industry increasingly adopts automation and digitalization, the demand for advanced robotic manipulators is expected to rise. These manipulators can enhance safety, efficiency, and productivity in energy production and maintenance processes.

Lukyanov’s research suggests that the future of industrial robotics lies in an interdisciplinary approach that combines engineering, software, and technological solutions. This approach could lead to the development of more sophisticated and versatile robotic manipulators, capable of performing a wider range of tasks in the energy sector.

As the energy sector continues to evolve, the role of industrial robotic manipulators is set to become even more crucial. Lukyanov’s research provides valuable insights into the current trends and future possibilities in this field, offering a roadmap for enterprises looking to harness the power of industrial robotics.

In the words of Lukyanov, “Industrial robotic manipulators continue to evolve, opening up new opportunities for automation and increased efficiency in production processes.” This evolution is not just a technological advancement; it’s a revolution that is reshaping the energy sector and paving the way for a more efficient and sustainable future.