In the relentless pursuit of enhancing cement concrete performance, researchers have turned to the nanoscale, and the results are promising. A recent study led by Svetlana A. Loginova from Yaroslavl State Technical University in Russia has shed light on the influence of nanoadditives on the physical and mechanical properties of cement concrete, offering a glimpse into the future of construction materials.

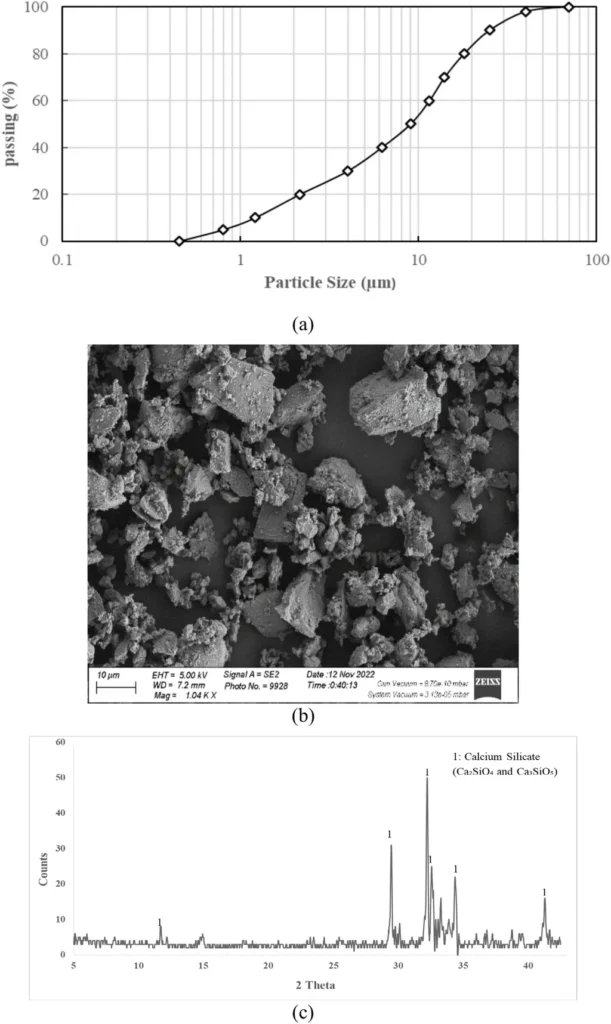

The study, published in the journal ‘Нанотехнологии в строительстве’ (Nanotechnologies in Construction), focuses on two experimental formulations of composite concrete nanoadditives: one based on ammonium hexafluorosilicate and the other on silicon carbide. The goal was to find the most promising and cost-effective solutions to boost concrete performance during in situ concreting.

Loginova and her team tested concrete samples after 28 days of hardening to assess mechanical strength properties. They found that the optimal combination of nanoparticles in the special additive significantly improved the strength characteristics of the concrete mix. “The use of the best additive formulation, combination No. 2, provided an average strength increase of 38%,” Loginova explained. This enhancement was confirmed through both destructive and non-destructive testing, marking a substantial leap in concrete technology.

The economic feasibility of this application is underscored by the optimal dosage of nanocomponents, which is approximately 0.0141 of the mass of the main raw material per cubic meter of concrete. This low concentration ensures environmental compatibility, minimizing the impact on the environment while contributing to the uniform distribution of particles in the concrete structure. As a result, the durability and resistance to environmental influences of the concrete are significantly improved.

The implications of this research for the energy sector are profound. Enhanced concrete performance can lead to more robust and long-lasting structures, reducing maintenance costs and improving safety. In the energy sector, where infrastructure often faces harsh environmental conditions, the use of these nanoadditives could extend the lifespan of critical facilities, from power plants to renewable energy installations.

Moreover, the environmental benefits cannot be overstated. The low concentration of nanoparticles ensures that the finished product is eco-friendly, aligning with the growing demand for sustainable construction materials. This could pave the way for greener energy infrastructure, reducing the carbon footprint of construction projects.

As the construction industry continues to evolve, the integration of nanotechnology offers a compelling path forward. The research by Loginova and her team highlights the potential of nanoadditives to revolutionize the way we build, offering stronger, more durable, and more sustainable materials. The future of construction is here, and it is nanoscale.

In the words of Loginova, “The optimal dosage of nanocomponents ensures the uniform distribution of particles in the concrete structure, contributing to an increase in its durability and resistance to environmental influences.” This breakthrough could very well shape the future of construction, making it more efficient, cost-effective, and environmentally friendly.