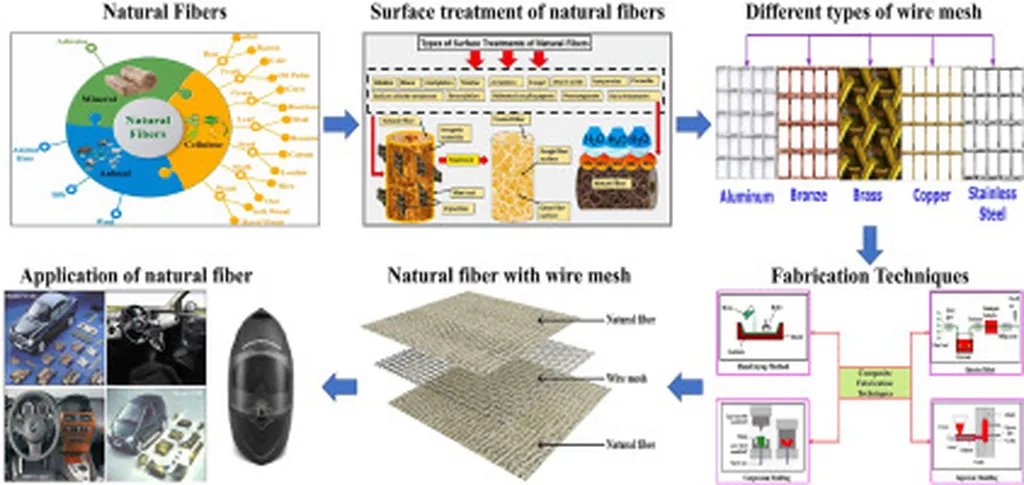

In the quest for sustainable and durable materials, researchers are increasingly turning to natural fiber composites, and a recent study published in *Materials Research Express* (which translates to “Materials Research Express” in English) is shedding new light on how to enhance these eco-friendly materials for high-performance applications. The study, led by Elayaraja R. from the School of Mechanical Engineering at the Vellore Institute of Technology in India, explores the potential of metal mesh reinforcements to significantly improve the wear and erosion resistance of natural fiber composites, opening up new possibilities for industries ranging from transportation to civil engineering.

Natural fiber composites have long been touted for their lightweight, biodegradable, and cost-effective properties, making them an attractive alternative to traditional materials. However, their practical use has been limited by issues such as micro-cracking, moisture sensitivity, and poor fiber-matrix adhesion, which can compromise their durability and reliability in harsh environments. “The challenge has been to enhance the mechanical and tribological properties of these composites without compromising their inherent advantages,” explains Elayaraja R.

The solution, according to the study, lies in embedding metal meshes made of materials like stainless steel, copper, or aluminum into the composite matrix. These meshes act as a reinforcing framework, improving interfacial bonding, promoting uniform stress transfer, and controlling fracture propagation. “By integrating metallic meshes, we can effectively address the weaknesses of natural fiber composites and tailor them for high-performance applications,” says Elayaraja R.

The research also highlights the potential of adding nanoscale reinforcements, which can further enhance the material’s properties through synergistic strengthening at different scales. The arrangement of the mesh, the orientation of the fibers, and the stacking sequence all play crucial roles in determining the extent of performance improvement. “The key is to engineer these composites at multiple scales to achieve optimal performance,” Elayaraja R. notes.

The study’s findings have significant implications for industries that require materials with superior wear and erosion resistance. For instance, in the energy sector, these enhanced composites could be used in braking systems, marine components, and protective coatings, where durability and reliability are paramount. The research also points to future directions involving hybrid multi-scale designs, engineered fiber-mesh interfaces, and predictive modeling strategies to achieve long-lasting tribological performance.

As industries continue to seek sustainable and high-performance materials, the insights from this study could pave the way for innovative solutions that balance environmental concerns with the demands of high-performance applications. With further research and development, metal mesh-reinforced natural fiber hybrid composites could become a game-changer in various industrial sectors, driving progress towards a more sustainable future.