In the quest to bolster the durability of construction materials, particularly those used in harsh environments, a recent study published in *Materials Research Express* has shed new light on the role of desulfurized gypsum (DSG) in enhancing the sulfate resistance of alkali-activated materials (AAMs). Led by Shuaixuan Chen from the College of Civil Engineering and Architecture at Jiaxing University in China, the research delves into how varying DSG content can significantly influence the performance of AAMs, including alkali-activated slag (AAS) and hybrid alkali-activated cement (HAC).

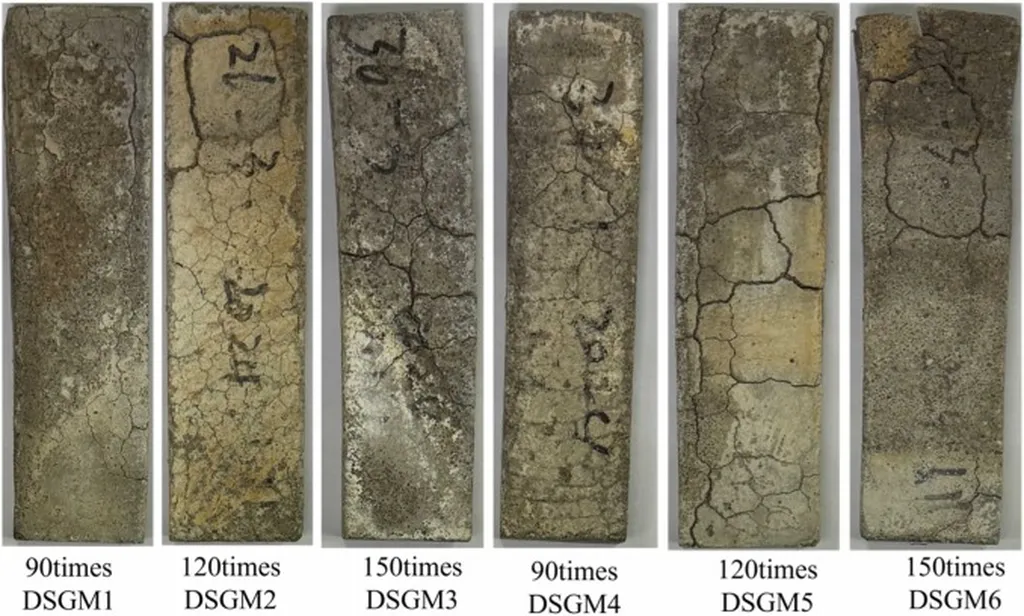

The study, which subjected specimens to accelerated corrosion via exposure to a sulfate environment combined with 150 dry-wet cycles, revealed a nuanced relationship between DSG content and sulfate resistance. “We found that the sulfate resistance of AAMs improves at 10% and 15% DSG content but deteriorates at 5% or 20%,” Chen explained. This finding underscores the critical importance of optimizing DSG content to achieve desired material properties.

The research employed X-ray diffraction (XRD) and scanning electron microscopy with energy-dispersive X-ray spectroscopy (SEM-EDS) to investigate the underlying mechanisms. The results showed that during sulfate attack, the increased formation of ettringite and hydrotalcite-like phases fills microcracks in the AAM matrix, producing a denser microstructure and enhanced corrosion resistance. However, when DSG content exceeds 15%, excessive crystal growth leads to additional cracking, thereby reducing corrosion resistance.

The implications of this research are substantial for the construction and energy sectors. As the demand for durable and sustainable building materials continues to grow, understanding how to optimize the use of DSG in AAMs could lead to significant advancements in material science. “Our findings provide a roadmap for developing more resilient construction materials that can withstand harsh environmental conditions,” Chen noted.

Moreover, the enhanced sulfate resistance of alkali-sulfur composite activated cementitious materials could have far-reaching impacts on infrastructure projects, particularly in regions with high sulfate soil or groundwater. This could translate into longer-lasting structures, reduced maintenance costs, and improved safety for energy infrastructure such as power plants and pipelines.

As the construction industry continues to evolve, the insights gained from this research could shape future developments in the field. By optimizing the use of DSG in AAMs, engineers and researchers can pave the way for more durable and sustainable construction materials, ultimately benefiting the energy sector and beyond. The study, published in *Materials Research Express* (which translates to *Materials Research Express* in English), marks a significant step forward in the ongoing quest to enhance the performance of construction materials in challenging environments.