In the quest to extend the lifespan of asphalt pavements and optimize their performance, a groundbreaking study led by Xinjie Man of Shandong Expressway Infrastructure Construction Co., Ltd., has harnessed the power of fiber Bragg grating (FBG) sensors. This innovative research, published in the journal *Advances in Civil Engineering* (translated from Chinese), delves into the dynamic mechanical response monitoring and fatigue life assessment of long-life asphalt pavements, offering promising insights for the construction and energy sectors.

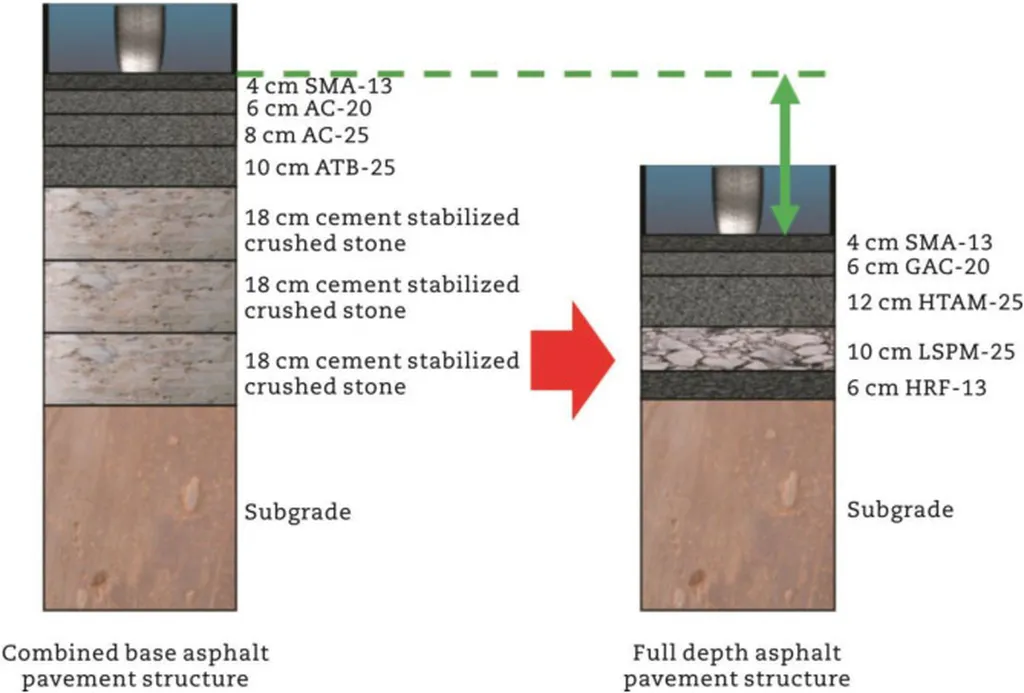

The study, rooted in real-world engineering projects, explores the application of FBG sensors to monitor the mechanical responses of asphalt pavement structures. Man and his team proposed a strategic deployment scheme for these sensors, which were embedded in various layers of the pavement, including the asphalt mixture surface layer, cement-stabilized crushed stone base, and inorganic binding material-stabilized soil base. This approach allowed for a comprehensive analysis of the pavement’s structural integrity and performance under different conditions.

One of the key findings of the study was the varying survival rates of the FBG sensors in different layers. “The survival rate of the sensors was not high under the actual working conditions of the pavement, with the surface layer sensors having the lowest survival rate,” Man noted. Despite this challenge, the activated sensors demonstrated excellent cooperative deformation characteristics with the materials in the surface layer, base layer, and subgrade. This capability enables engineers to evaluate the uniformity of the structural layer construction rolling process and monitor the structural mechanical response of the pavement under dynamic loading.

The research also shed light on the evolution patterns of field dynamic response and fatigue life of the pavement under different vehicle axle loads, axle types, and speeds. The findings revealed that under dynamic load, the longitudinal tensile strain of the asphalt mixture layer and the inorganic binding material stabilized layer bottom was larger than the transverse tensile strain. Both longitudinal and transverse tensile strains increased with the increase of load and decreased with the increase of vehicle speed. These insights are crucial for understanding the fatigue life of pavement structures, which decreases with increasing load and increases with increasing speed.

The study’s implications for the energy sector are significant. By improving the durability and performance of asphalt pavements, this research can contribute to reducing maintenance costs and extending the lifespan of road infrastructures. This, in turn, can lead to more efficient transportation networks, which are vital for the energy sector’s supply chain and logistics operations.

Moreover, the findings can inform the development of more resilient and sustainable pavement materials, which are essential for mitigating the environmental impact of road construction and maintenance. As the world transitions towards cleaner energy sources, the demand for efficient and sustainable transportation infrastructure will only grow, making this research all the more relevant.

In the words of Man, “This study provides a valuable tool for evaluating and analyzing the uniformity of the structural layer construction rolling process and the monitoring of the structural mechanical response of the pavement under dynamic loading.” The insights gained from this research can pave the way for future developments in the field, ultimately leading to more robust, efficient, and sustainable road infrastructures.