In the relentless pursuit of materials that can withstand the harshest environments, a team of researchers led by Jun Fan at the State Key Laboratory of Advanced Marine Materials in China has made a significant stride. Their work, published in the journal Corrosion Communications, focuses on high-entropy alloys (HEAs), a class of materials that have garnered considerable attention for their exceptional mechanical properties. The research delves into the corrosion and wear behaviors of AlCoCr1+xFe1-xNi2.1 HEAs, offering promising insights for industries where material durability is paramount, particularly the energy sector.

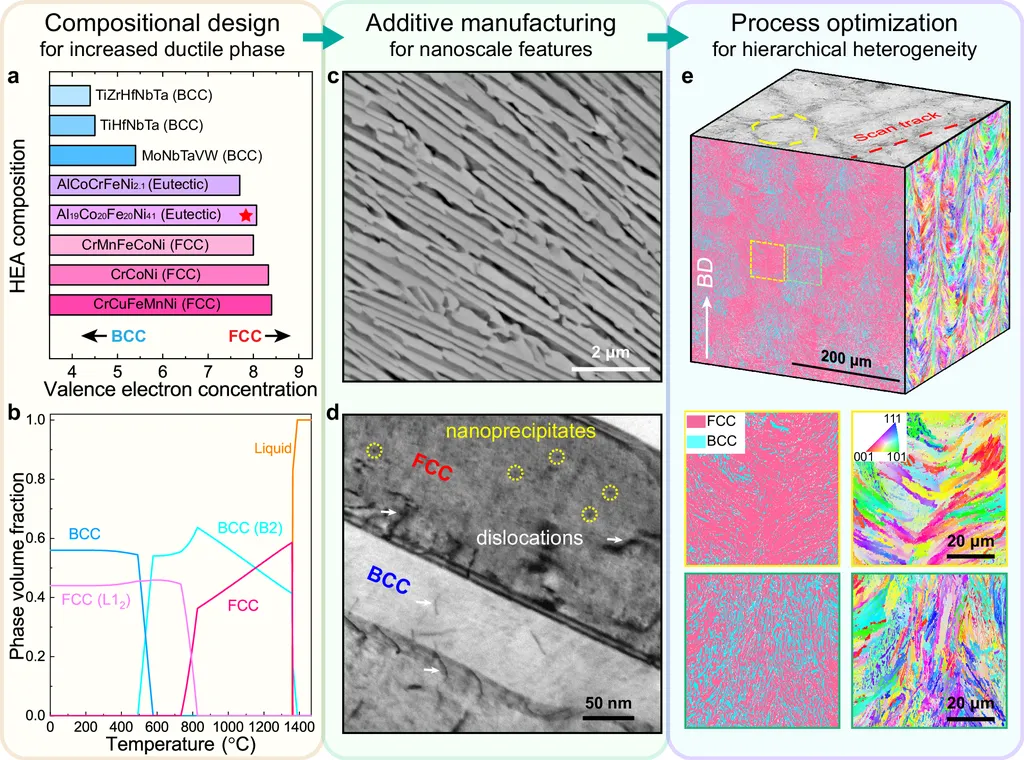

High-entropy alloys are known for their impressive strength and fracture toughness, but their susceptibility to localized corrosion due to uneven phase composition has been a persistent challenge. Fan and his team addressed this issue by designing and preparing AlCoCr1+xFe1-xNi2.1 HEAs using the calculation of phase diagrams (CALPHAD) method. The alloys were then subjected to vacuum arc melting to achieve a multiphase structure comprising face-centered cubic (FCC), body-centered cubic (BCC), and ordered body-centered cubic (B2) phases.

The study revealed that increasing the Cr/Fe ratio in the alloys led to a decrease in the volume fraction of the FCC/B2 lamellar eutectic microstructure, while the volume fraction of the BCC/B2 coherent network microstructure increased. This structural transformation resulted in enhanced corrosion resistance, as evidenced by lower corrosion current densities and higher corrosion potentials. “The protective passive film’s formation depends on the Cr and Al content,” explained Fan. “The Cr-rich coherent nanophases in the Al-rich B2 phase result in a more homogeneous and thicker passive film, which can inhibit the expansion of corrosion pits.”

The research also highlighted the importance of appropriate phase fractions for advanced wear resistance. The optimal phase distribution was found to be approximately 33.56% FCC and 66.44% BCC/B2. The wear rate of all the HEAs was remarkably low, around 10–5 mm3/(N·m), with oxidation wear and abrasive wear playing dominant roles. “This study provides an attractive strategy for the development of corrosion-resistant and wear-resistant high-entropy alloys,” Fan noted.

The implications of this research are profound for the energy sector, where materials are often exposed to extreme conditions. For instance, in offshore wind turbines, the blades and structural components are subjected to constant wear and corrosion from seawater and wind. Similarly, in oil and gas exploration, drilling equipment must endure high temperatures and pressures, as well as corrosive environments. The development of high-entropy alloys with superior corrosion and wear resistance could significantly extend the lifespan of these critical components, reducing maintenance costs and improving overall efficiency.

Moreover, the findings could pave the way for the development of new HEAs tailored for specific applications. By understanding the relationship between phase composition, corrosion resistance, and wear resistance, researchers can design materials that meet the unique demands of various industries. “This research opens up new possibilities for the development of advanced materials that can withstand the harshest environments,” Fan said.

As the energy sector continues to evolve, the demand for durable and high-performance materials will only grow. The work of Jun Fan and his team represents a significant step forward in meeting this demand, offering a glimpse into a future where materials are not just stronger but also more resilient against the ravages of time and environment. Published in the journal Corrosion Communications, this research is a testament to the power of innovative materials science in shaping the future of industry.