In the quest to bolster the resilience of materials in harsh environments, a team of researchers led by Xing-Shou Zhang from the School of New Energy and Materials at Southwest Petroleum University and the University of Alberta has made significant strides. Their work, published in *Corrosion Communications* (which translates to *Anti-corrosion Communication*), focuses on the synergistic effects of temperature and CO2 on the corrosion behavior and mechanism of laser cladding Ni/WC composite coatings. This research could have profound implications for the energy sector, particularly in environments where materials are exposed to high temperatures and pressures.

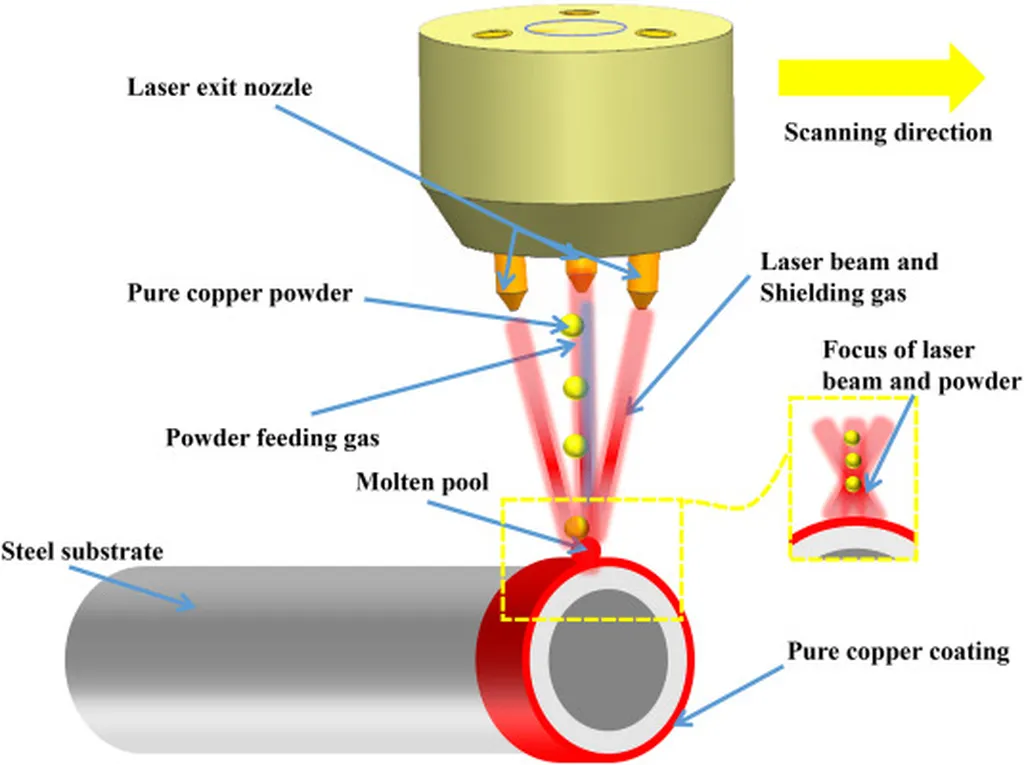

The study employed laser cladding technology to fabricate a Ni/WC composite coating on 4145H steel. This technique is known for its ability to enhance the surface properties of materials, making them more resistant to wear and corrosion. The researchers found that the coating predominantly consists of austenitic dendrites (γ-Ni), WC particles, and fishbone-like precipitates, including W2C, MoC, and CrC. These microstructural features play a crucial role in the coating’s performance under different conditions.

Electrochemical results revealed that as temperature increases without CO2, there is a notable decrement in polarization resistance (Rp) and an increment in corrosion current density (icorr). This indicates that the material becomes more susceptible to corrosion at higher temperatures. However, the presence of CO2 at 1.5 MPa and 80 °C significantly exacerbates the situation, with icorr being approximately 7 times lower than that under CO2-free conditions. “The synergistic effect of temperature and CO2 is particularly concerning,” noted Zhang. “It highlights the need for advanced materials that can withstand these harsh conditions.”

The corrosion mechanism analysis further illustrated that galvanic cell corrosion between WC particles and Inconel 625 causes pitting corrosion. This issue is further compounded by the deposition of CaCO3 and MgCO3 on WC particles as both temperature and pressure escalate. Understanding these mechanisms is crucial for developing more robust materials that can operate efficiently in high-pressure, high-temperature environments.

The implications of this research are far-reaching, particularly for the energy sector. Oil and gas extraction, for instance, often involves operating in environments with high temperatures and CO2 pressures. The findings could lead to the development of more durable materials that can withstand these conditions, reducing maintenance costs and improving operational efficiency. “This research provides a foundation for future developments in material science,” said Zhang. “By understanding the underlying mechanisms, we can design materials that are not only more resistant to corrosion but also more cost-effective.”

As the energy sector continues to evolve, the need for materials that can withstand extreme conditions becomes increasingly critical. The work of Zhang and his team offers valuable insights that could shape the future of material development, ensuring that the energy infrastructure remains robust and reliable. With the publication of this research in *Corrosion Communications*, the scientific community now has a clearer understanding of the challenges and opportunities in this field.