In the relentless pursuit of materials that can withstand the harshest industrial environments, researchers have turned to bimetallic joints, combining the strengths of dissimilar metals. A recent study published in *Frontier of Materials and Technologies* (English translation of ‘Frontier Materials & Technologies’) explores a novel approach to assessing the phase composition of these joints, with significant implications for the energy sector.

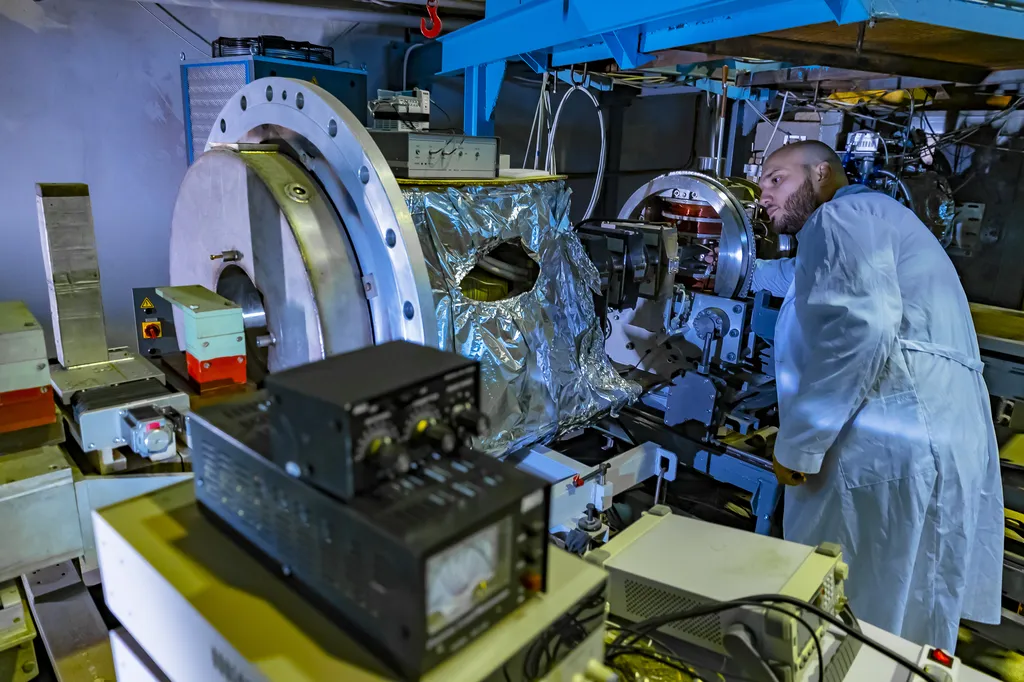

The research, led by Matvei V. Lapin from the Institute of Engineering Science, Ural Branch of RAS in Yekaterinburg, Russia, focuses on a bimetallic joint created by arc welding Er308LSi austenitic stainless steel wire onto St3 carbon steel. The study aims to evaluate the feasibility of using magnetic non-destructive testing methods to analyze the phase composition of such joints, even after deformation.

Lapin and his team conducted metallographic and X-ray diffraction studies on the bimetallic material. They then subjected samples cut from different parts of the material to step-by-step plastic deformation tests. After each deformation step, they measured the magnetic hysteresis loops of the samples in an unloaded state.

The researchers found that existing methods for estimating the martensite phase content based on magnetic properties were not straightforward to apply. This complexity arises from the material’s intricate structural and phase composition, which includes a second peak of differential magnetic permeability for ferrite in St3 steel, ferrite in the upper deposited austenitic layers, and martensite in the first layer.

To address this, the team proposed a new parameter based on the asymmetry of the difference in the field dependences of differential magnetic permeability. This parameter showed a clear correlation with the magnitude of plastic deformation and, consequently, with the content of deformation martensite.

“This new approach allows us to better understand the phase composition of bimetallic joints, which is crucial for predicting their behavior under various conditions,” Lapin explained. “This understanding can lead to the development of more robust and reliable materials for use in aggressive environments, such as those found in the energy sector.”

The energy sector, with its demanding environments and high mechanical loads, stands to benefit significantly from this research. By enabling more accurate assessments of material composition and behavior, this method could enhance the safety and efficiency of energy infrastructure, from pipelines to power plants.

As the energy sector continues to evolve, the need for advanced materials that can withstand extreme conditions will only grow. This research paves the way for future developments in material science, offering a promising avenue for creating materials that are not only stronger and more durable but also more adaptable to the ever-changing demands of modern industry.

In the words of Lapin, “This is just the beginning. The potential applications of this method are vast, and we are excited to explore them further.”