In the ever-evolving landscape of materials science and sensor technology, a groundbreaking development has emerged from the University of Hail in Saudi Arabia. Researchers, led by Ahmed Alzamil from the Department of Electrical Engineering, have designed a highly efficient metamaterial (MTM) absorber that could revolutionize oil quality sensing and potentially reshape industrial practices in the energy sector.

The innovative absorber, detailed in a recent study published in the Journal of Science: Advanced Materials and Devices (or, in English, “Journal of Science: Advanced Materials and Devices”), leverages a compact maze-shaped structure composed of a copper resonator and a Rogers 5880 substrate. This design achieves near-perfect absorption efficiency (> 99%) across the 2–5 GHz frequency range, a significant leap forward in sensor technology.

Alzamil and his team delved into the geometric parameters of the absorber, discovering that increasing the complexity of the resonator’s design substantially enhanced multi-band performance and resonance tuning. “By meticulously adjusting the geometric parameters, we were able to achieve unprecedented levels of sensitivity and accuracy in distinguishing different types of edible oils,” Alzamil explained. This precision is crucial for applications in quality control and food safety, where even minor variations in oil quality can have significant impacts.

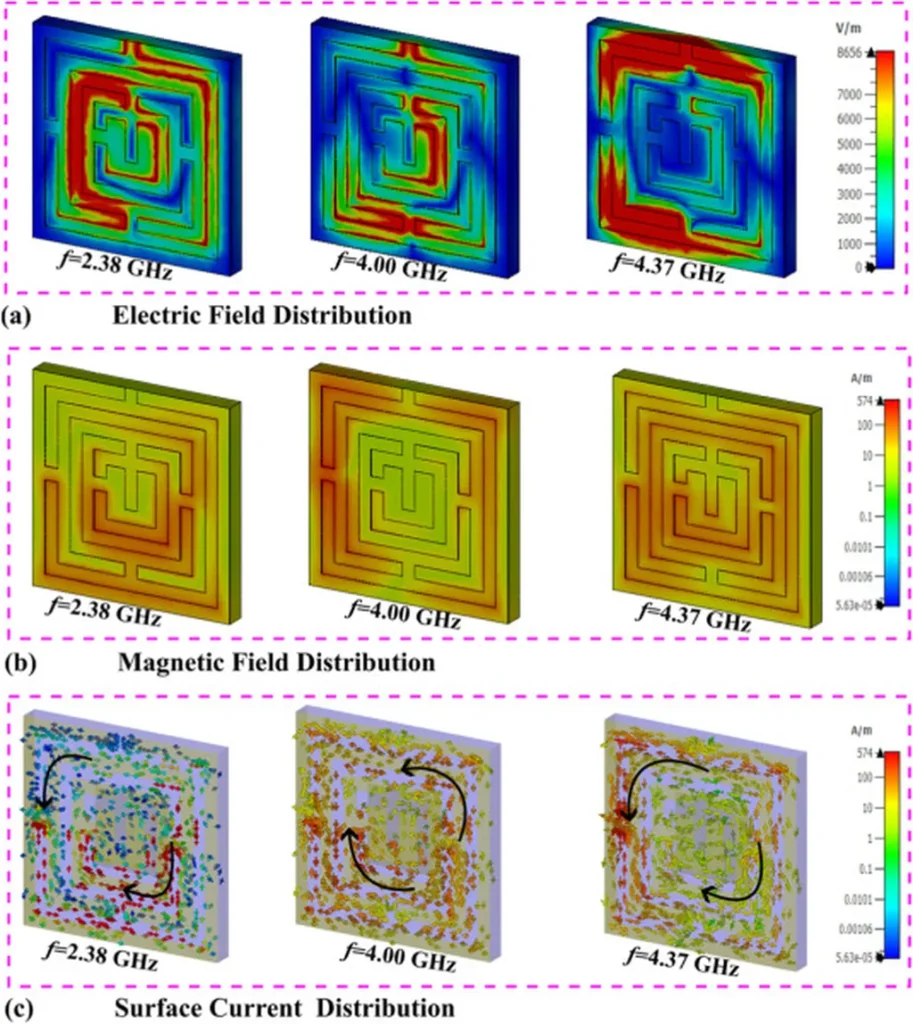

The study employed comprehensive simulations using CST Microwave Studio, validated through equivalent circuit modeling, to establish a robust design methodology. Experimental verification further confirmed the absorber’s sensitivity, demonstrating distinct resonance-frequency shifts for mustard, coconut, and sunflower oils. These shifts are directly attributable to the dielectric constants of the oils, highlighting the sensor’s potential for industrial applications.

The sensor achieved an exceptional quality factor (Q = 170) and high sensitivity (0.85 GHz per dielectric unit), positioning it as a promising candidate for industrial use. “This technology not only enhances our ability to ensure food safety but also opens up new avenues for quality control in the energy sector,” Alzamil noted. The implications for the energy industry are profound, as accurate oil quality sensing can lead to more efficient refining processes, reduced waste, and improved product consistency.

As the world continues to seek innovative solutions for quality control and safety, this research offers a glimpse into the future of sensor technology. The development of such advanced metamaterial absorbers could pave the way for more precise and reliable sensing applications across various industries. With further refinement and commercialization, this technology has the potential to set new standards in industrial practices, ensuring higher quality and safety for consumers worldwide.