In the relentless pursuit of cleaner water and more efficient industrial processes, researchers have made a significant stride in the realm of wastewater treatment. A team led by Hailemariam Assefa from the Faculty of Material Science and Engineering has developed a novel composite material that could revolutionize the removal of hexavalent chromium (Cr(VI)) from wastewater. This breakthrough, published in the journal ‘Nanomaterials and Nanotechnology’ (translated to ‘Nanomaterials and Nanotechnology’), holds promising implications for the energy sector and beyond.

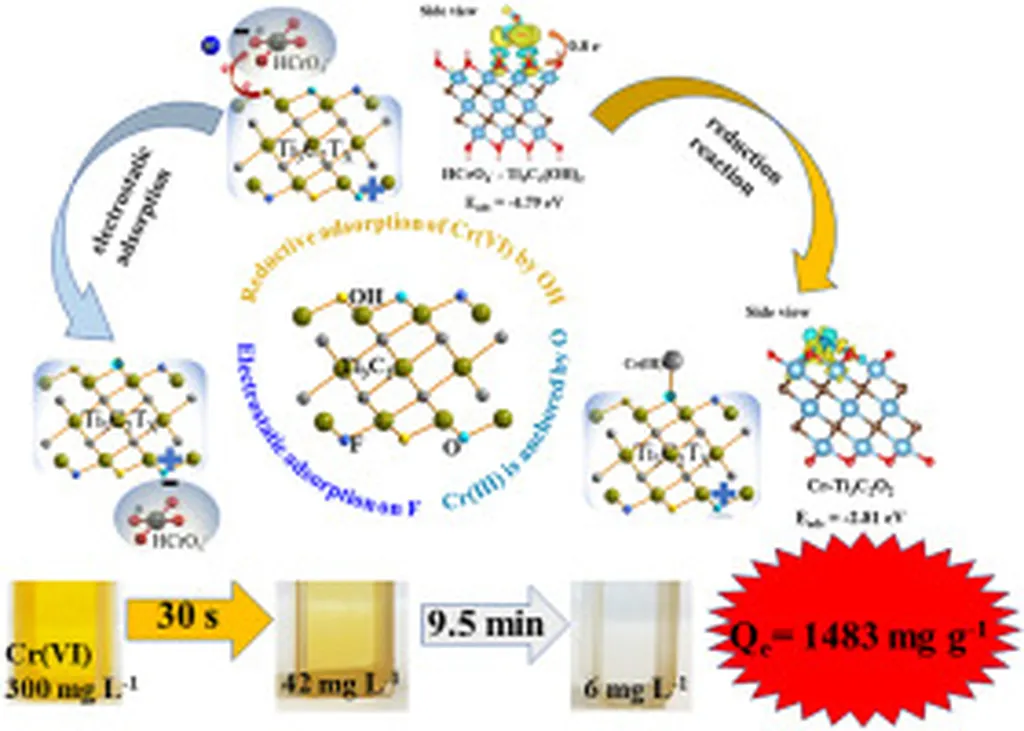

The study introduces a composite made from polyaniline-functionalized Ti3C2Tx MXene, a material that combines the conductive properties of polyaniline (PANI) with the high surface reactivity of Ti3C2Tx layers. This synergistic interaction enhances active site accessibility and electron transfer, making it a highly efficient adsorbent for Cr(VI).

“Our findings demonstrate that the Ti3C2Tx/PANI composite exhibits a remarkably high adsorption capacity of 342.5 mg/g,” Assefa explained. “This performance surpasses many previously reported MXene and PANI-based adsorbents, offering a robust solution for Cr(VI) removal.”

The adsorption performance of the composite is significantly influenced by the pH level of the solution, with optimal results achieved at an acidic pH. The study also revealed that the composite maintains its adsorption efficiency over seven cycles, indicating its stability and reusability.

The research employed various characterization techniques, including XRD, FTIR, SEM–EDS, XPS, and Raman spectroscopy, to verify the successful synthesis and adsorption capabilities of the composite. The experimental data aligned well with the Langmuir–Freundlich and Khan isotherm models, while the pseudo-second-order and MESO kinetic models best described the adsorption process.

The implications of this research are far-reaching, particularly for the energy sector. Hexavalent chromium is a common contaminant in industrial wastewater, particularly in processes related to electroplating, leather tanning, and energy production. Effective removal of Cr(VI) is crucial for environmental safety and regulatory compliance.

“This composite material could be a game-changer in wastewater treatment, offering a more efficient and cost-effective solution for industries dealing with Cr(VI) contamination,” Assefa noted. “Its high adsorption capacity and stability make it a promising candidate for large-scale applications.”

The study’s findings open new avenues for developing advanced materials for water treatment and other environmental applications. The synergistic interaction between PANI and Ti3C2Tx layers highlights the potential of combining conductive polymers with high-surface-area materials to enhance adsorption performance.

As industries strive for more sustainable and environmentally friendly practices, innovations like the Ti3C2Tx/PANI composite play a pivotal role. The research not only advances the field of materials science but also contributes to the broader goal of achieving cleaner and safer industrial processes.

In the quest for cleaner water and more efficient industrial processes, this breakthrough offers a beacon of hope, demonstrating the power of innovative materials in addressing critical environmental challenges.