In the quest for sustainable and efficient machining processes, researchers have turned to an unusual ally: graphene nanoplatelets and corn oil. A recent study led by Pungky Eka Setyawan from the Faculty of Engineering at Universitas Brawijaya in Malang, Indonesia, has unveiled promising results that could reshape the future of cutting fluids in the manufacturing industry.

The study, published in the journal *Tribology and Materials* (which translates to *Friction and Materials*), focuses on the potential of corn oil-based cutting fluids infused with graphene nanoplatelets (GNPs) to enhance surface quality and machining performance. This research is particularly relevant for the energy sector, where precision machining of materials like AISI 1045 steel is crucial for producing high-quality components.

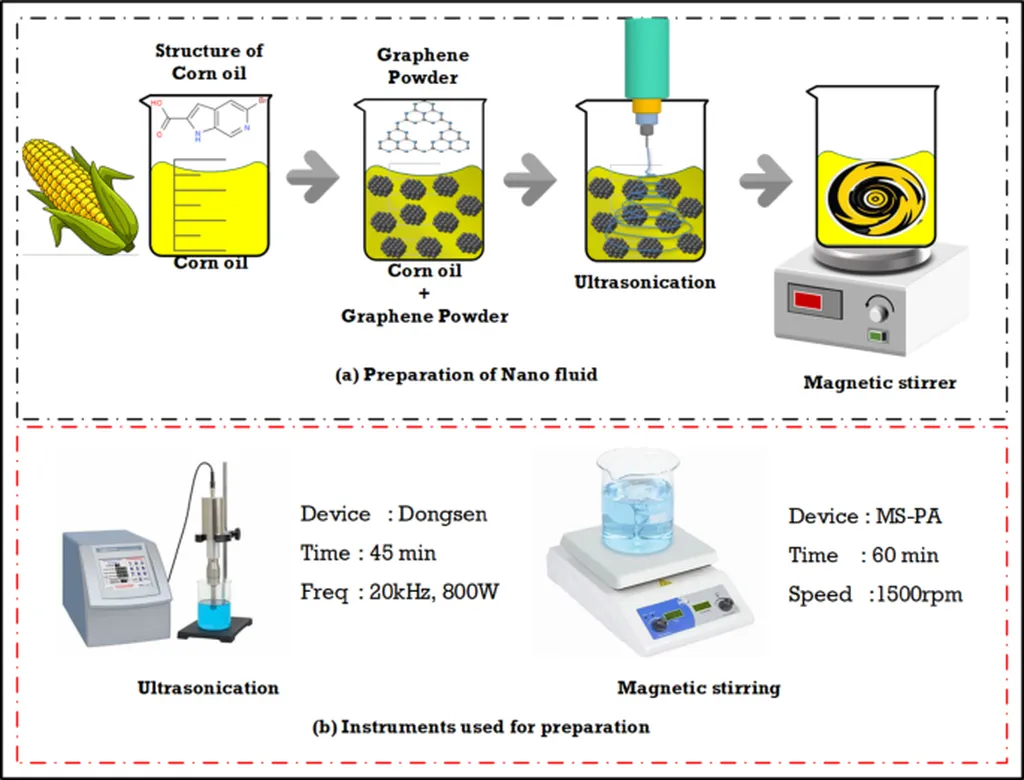

Traditional cutting fluids, while effective, pose significant environmental and health risks due to their long-term use. Setyawan’s research explores the minimum quantity lubrication (MQL) method, which uses a minimal amount of cutting fluid, significantly reducing these risks. The study found that the addition of GNPs to corn oil-based cutting fluids can reduce surface roughness by up to 74% compared to dry cutting conditions.

“The results were quite remarkable,” said Setyawan. “The thin graphene layer formed on the tool morphology not only reduced friction but also minimized the built-up edge, which is a common issue in machining processes.”

The study involved various conditions, including dry cutting, MQL with corn oil, and MQL with corn oil and added GNPs at different concentrations (0.10 – 0.30 wt. %). The optimal concentration of GNPs was found to be 0.25 wt. %, which produced C-shape chips, indicating high deformation and efficient machining.

The implications of this research are far-reaching. For the energy sector, where precision and efficiency are paramount, the use of corn oil-based cutting fluids with GNPs could lead to significant improvements in product quality and machining performance. This could translate to cost savings and reduced environmental impact, as the need for traditional cutting fluids decreases.

As the industry continues to seek sustainable and efficient solutions, Setyawan’s research offers a glimpse into the future of machining processes. The integration of nanotechnology and bio-based materials could pave the way for more environmentally friendly and economically viable manufacturing practices.

“This study is just the beginning,” Setyawan added. “We are excited about the potential applications and the positive impact it could have on the industry.”

In an era where sustainability and efficiency are key drivers, this research could shape the future of machining, offering a greener and more effective alternative to traditional cutting fluids.