In a groundbreaking development for the energy sector, researchers have successfully modeled and verified the quenching process for CM690 anchor chain steel, a critical material for offshore and deep-sea applications. The study, led by Yang Chengwei, was recently published in the journal ‘Teshugang’, which translates to ‘Iron and Steel’ in English.

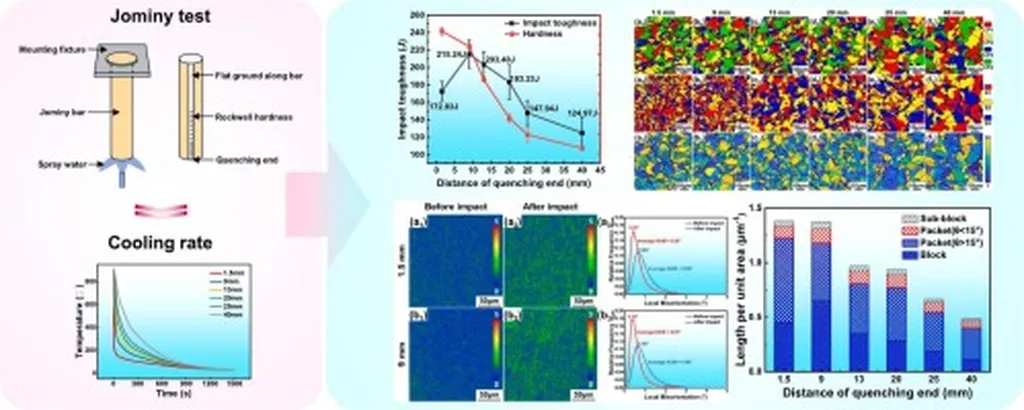

The research team developed a sophisticated numerical simulation model using COMSOL Multiphysics 6.3 software to describe the steel quenching process. The model accurately predicts the temperature distribution and microstructure evolution of CM690 steel during the Jominy end-quench test, a crucial method for evaluating the hardenability of steels.

“Our model can precisely simulate the temperature and microstructure fields during the quenching process,” said Yang Chengwei, the lead author of the study. “This is a significant advancement as it allows us to better understand and control the properties of high-strength steels used in demanding environments.”

The Jominy test revealed that the specimen exhibits quasi-one-dimensional heat transfer characteristics. As the distance from the quenched end increases, the cooling rate gradually decreases, resulting in a gradient distribution of the microstructure. Martensite, known for its high hardness and strength, is mainly concentrated in the 0 mm to 20 mm range. Bainite appears from 9 mm to 40 mm away from the quenching end, while pearlite and ferrite are distributed further along the specimen.

The experimental verification of the model showed that the observed microstructure of the dilatometric specimens at different distances from the quenched end was highly consistent with the simulation predictions. Furthermore, the Vickers hardness values measured for both the Jominy test specimen and the dilatometric specimen showed the same trend of change, further validating the model’s reliability and applicability.

This research has significant implications for the energy sector, particularly for offshore wind farms and deep-sea oil and gas exploration. The accurate prediction of steel properties during the quenching process can lead to the development of stronger, more durable anchor chains and other critical components, reducing maintenance costs and improving safety.

“The ability to predict and control the microstructure of high-strength steels is a game-changer for the energy sector,” said a senior industry expert who wished to remain anonymous. “This research could lead to significant advancements in the design and manufacture of components for offshore and deep-sea applications.”

As the energy sector continues to push the boundaries of exploration and development in challenging environments, the need for high-performance materials will only grow. This research, published in ‘Teshugang’, provides a vital tool for meeting that need, paving the way for safer, more efficient, and more cost-effective energy production.

The study’s findings not only validate the model’s accuracy but also open up new possibilities for optimizing the quenching process and tailoring the properties of CM690 steel for specific applications. As the energy sector continues to evolve, this research will undoubtedly play a crucial role in shaping the future of offshore and deep-sea infrastructure.