In the quest to enhance the reliability and performance of high-strength oil casing, a recent study published in *Teshugang* (which translates to *Iron and Steel*) has shed light on the critical role of nonmetallic inclusions in impacting the toughness of these essential components. Led by Deng Xuyan, the research delves into the intricate world of inclusions within continuous casting billets, offering insights that could reshape manufacturing processes and quality control in the energy sector.

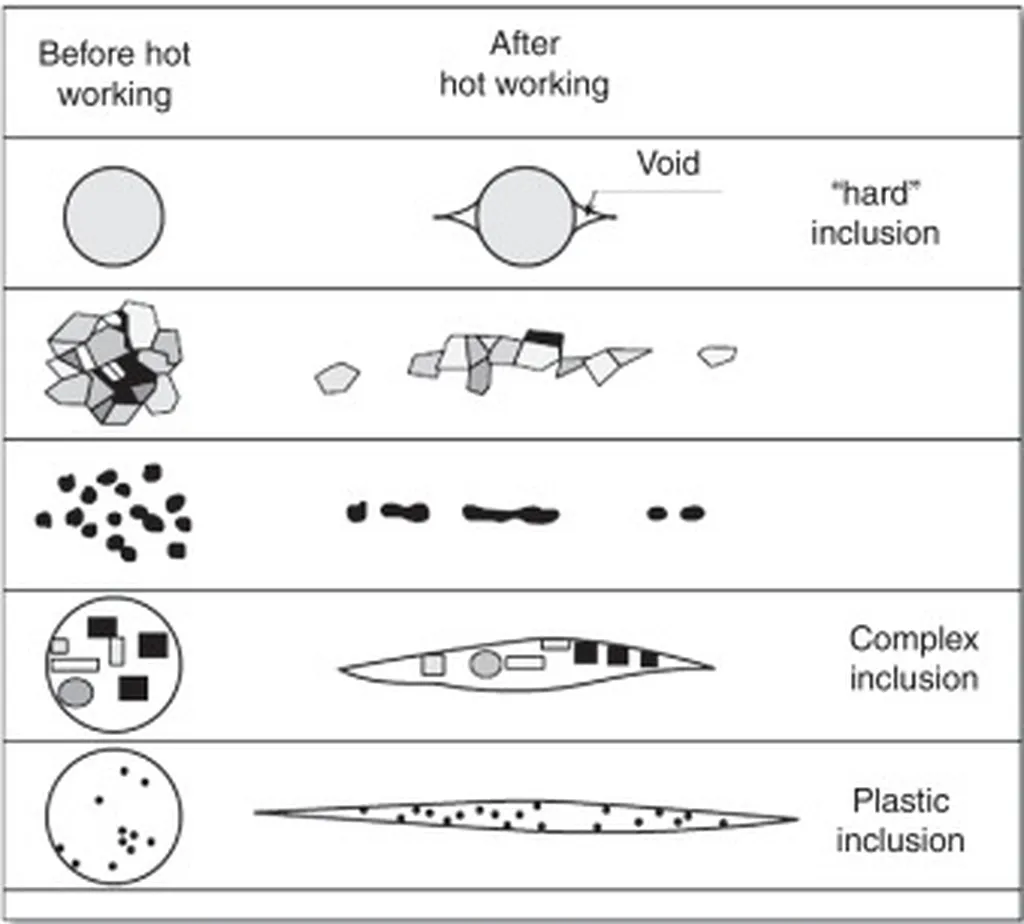

The study, which analyzed the number, size, chemical composition, and morphology of inclusions using advanced techniques like SEM and bulk sample electrolysis, revealed that the initial stages of casting are particularly prone to higher levels of micro and macro inclusions. “The fluctuations in impact energy observed in seamless steel pipes produced from these billets are directly linked to the presence and characteristics of nonmetallic inclusions,” Deng Xuyan explained. This finding underscores the importance of meticulous control during the casting process to ensure the production of high-quality oil casing.

One of the most compelling discoveries was the significant variation in impact energy, with the maximum energy being 1.4 times the minimum. This variability was found to decrease as the total oxygen (T.O) content in the steel increased, highlighting the detrimental effect of oxygen on the material’s toughness. Moreover, samples with lower impact energy exhibited a higher area fraction of inclusions, with the inclusion area fraction in the 37 J sample being 2.1 times that of the 53 J sample. “Nonmetallic inclusions are the primary cause of these fluctuations,” Deng Xuyan asserted, emphasizing the need for stringent quality control measures.

The implications of this research are far-reaching for the energy sector, particularly in the production of high-strength oil casing. By understanding and mitigating the impact of nonmetallic inclusions, manufacturers can enhance the toughness and reliability of their products, ultimately improving the safety and efficiency of oil and gas operations. The study’s findings could lead to advancements in casting technologies and quality control protocols, ensuring that the oil casing meets the stringent demands of the energy industry.

As the energy sector continues to evolve, the insights provided by Deng Xuyan and their team will be instrumental in driving innovation and improving the performance of high-strength oil casing. The research, published in *Teshugang*, serves as a testament to the ongoing efforts to optimize manufacturing processes and elevate the standards of quality in the industry. With a deeper understanding of the role of nonmetallic inclusions, the future of oil casing production looks brighter and more resilient than ever before.