In the rapidly evolving world of additive manufacturing, predicting the mechanical properties of complex lattice structures has long been a stumbling block. But a recent study published in *Discover Materials* (translated from Russian as “Explore Materials”) offers a promising solution, potentially revolutionizing how industries—particularly energy—approach design and production.

The research, led by Mustak Shaikh from the Department of Mechanical Engineering at Symbiosis Institute of Technology, Symbiosis International (Deemed University), introduces a hybrid machine learning framework that combines metaheuristic optimization algorithms with traditional machine learning techniques. The goal? To accurately predict the compressive strength of FDM-printed Polylactic Acid (PLA) lattice structures—a critical factor in their real-world application.

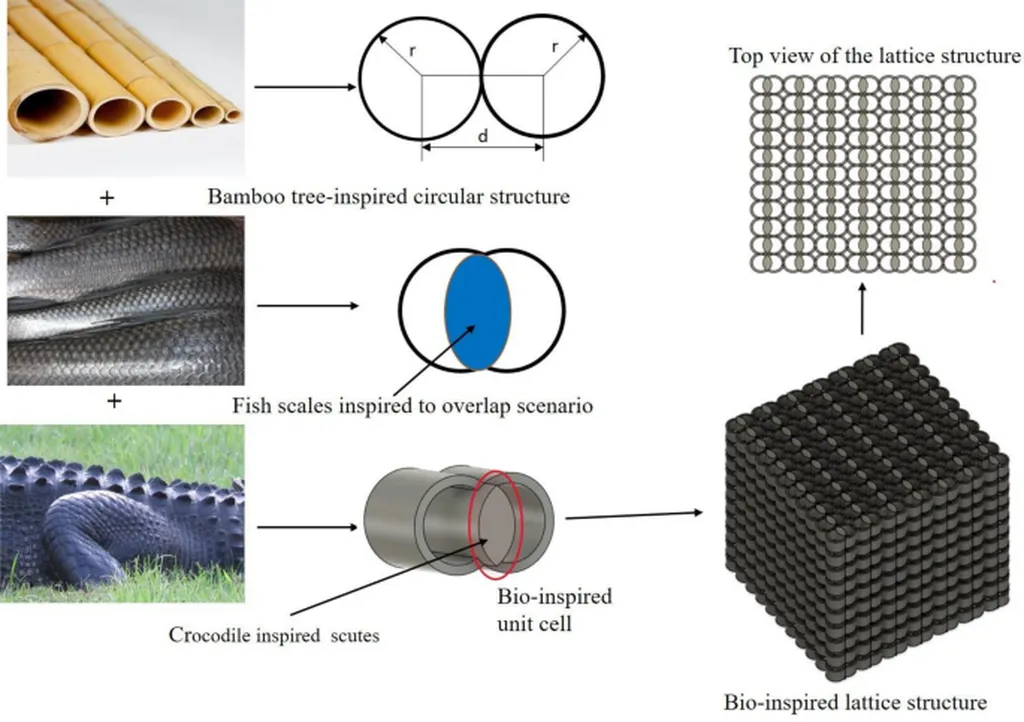

Shaikh and his team used experimental data from 25 physical specimens, focusing on key design features like infill density, infill pattern, strut diameter, and strut type. The hybrid model, which integrates algorithms like Genetic Algorithm (GA), Particle Swarm Optimization (PSO), and Support Vector Machine (SVM), achieved remarkable results. The SVM-GA hybrid model, in particular, stood out with an R² of 0.874, a significant improvement over the baseline SVM model.

“This study bridges the gap between machine learning and domain expertise,” Shaikh explained. “By leveraging hybrid algorithms, we’ve created a robust, interpretable framework that minimizes the need for costly trial-and-error experimentation.”

The implications for the energy sector are substantial. Lattice structures are increasingly used in energy applications, from lightweight components in wind turbines to complex geometries in nuclear reactors. Accurate predictive modeling can streamline design processes, reduce material waste, and enhance the performance of these components.

“Our framework provides a validated tool for AM design optimization,” Shaikh added. “It’s not just about predicting compressive strength; it’s about making the entire process more efficient and cost-effective.”

The study also employed SHAP (SHapley Additive exPlanations) analysis to enhance model interpretability, identifying infill density and strut diameter as the most influential features. This aligns with fundamental mechanical principles, reinforcing the model’s reliability.

While the current study is limited by a constrained dataset size, future work will focus on expanding data diversity and incorporating additional process variables. The potential for real-time predictive capabilities is also on the horizon, a development that could further transform the additive manufacturing landscape.

As industries continue to push the boundaries of what’s possible with additive manufacturing, this research offers a glimpse into a future where design and production are driven by data, precision, and efficiency. For the energy sector, this could mean lighter, stronger, and more cost-effective components, ultimately contributing to more sustainable and innovative energy solutions.

Published in *Discover Materials*, this study is a testament to the power of interdisciplinary collaboration, combining the strengths of machine learning and mechanical engineering to solve real-world problems. As Shaikh and his team continue their work, the potential applications of their framework are vast, promising to shape the future of additive manufacturing and beyond.