In the heart of Slovakia, a team of engineers from the University of Žilina has been tackling a persistent problem in the woodworking industry: the unreliable transport of logs to mobile working machines. Led by Miroslav Blatnický from the Department of Transport and Handling Machines, the research team has published their findings in the journal Open Engineering (translated from Slovak as “Open Engineering”), offering a solution that could reshape the way the energy sector handles biomass.

The issue at hand is a familiar one for many in the industry. Despite purchasing state-of-the-art mobile working machines, operators often find themselves grappling with log transport systems that fail to meet expectations. “Even multiple complaints do not necessarily mean that an unfavourable condition has been corrected,” Blatnický notes, highlighting the gap in the market that his team aimed to address.

The problem lies in the initial design of the machines. Many are equipped with roller transport systems driven by human power, which struggle to handle logs of the prescribed maximum diameter. Even when manufacturers replace these with hydraulically driven belt conveyors, the issue persists. “Even this modification did not ensure the possibility of at least sufficient manipulation of the logs,” Blatnický explains.

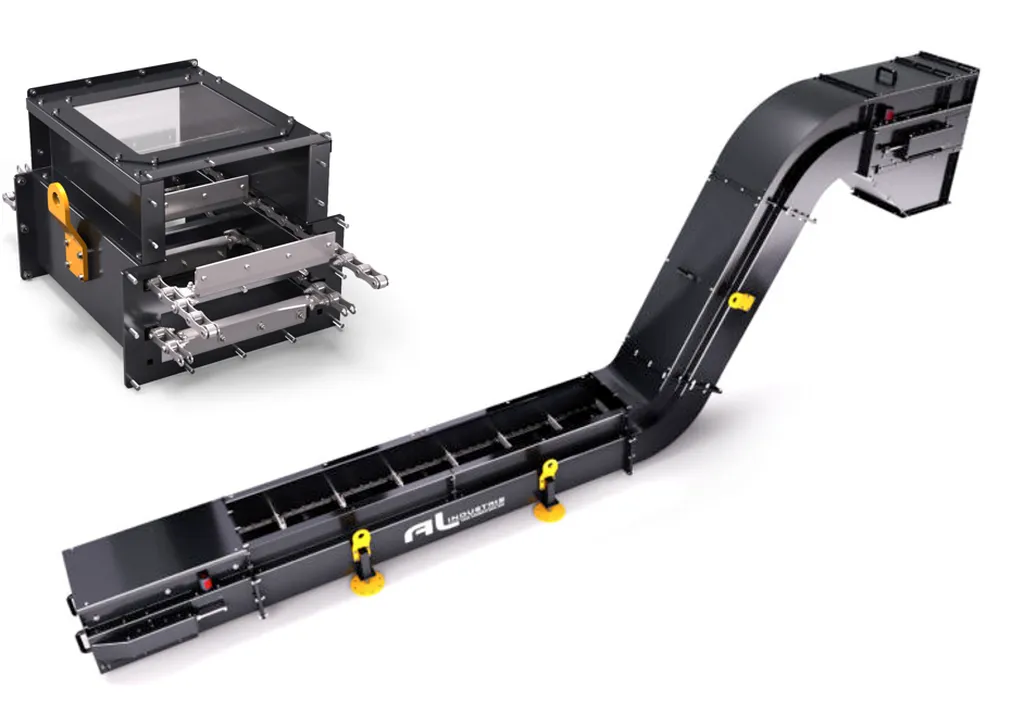

To overcome this challenge, the team designed a special adapted two-piece chain conveyor. The crux of their research, published in Open Engineering, focuses on the design of the conveyor’s two shafts. Using principles of construction, analytical and numerical calculations, and functional and dimensional analysis, they ensured the conveyor’s safe and reliable use.

The impact of this research on the energy sector could be significant. Efficient and reliable log transport is crucial for biomass processing, a key component of the renewable energy mix. By improving the handling of logs, this research could enhance the overall efficiency of biomass processing plants, reducing downtime and increasing productivity.

Moreover, the team’s approach could inspire future developments in the field. As Blatnický puts it, “The design was carried out using the principles of construction, analytical and numerical, functional and dimensional calculations, which ensure its safe use.” This methodical approach could be applied to other areas of machine design, leading to more robust and reliable equipment.

The team’s work is a testament to the power of persistent problem-solving. By addressing a seemingly small issue, they have opened up possibilities for significant improvements in the industry. As the energy sector continues to evolve, research like this will be crucial in driving progress and innovation.