In the quest for sustainable construction materials, researchers have turned to an unlikely ally: coconut shells. A recent study led by Elaiyawar Maheswari from SRM Valliammai Engineering College in Chennai, India, explores the potential of coconut shell ash (CSA) as a partial replacement for cement in concrete manufacturing. The findings, published in the journal *Advances in Civil and Architectural Engineering* (which translates to *Advances in Civil and Architectural Engineering*), offer a promising avenue for reducing the environmental footprint of the construction industry.

Cement production is a significant contributor to global carbon dioxide emissions, with the industry accounting for billions of tons of CO2 annually. Meanwhile, coconut shells, a common agricultural byproduct, often end up as waste. Maheswari’s research aims to address both issues by investigating the feasibility of using CSA as a cement substitute and coconut fibers as reinforcements in concrete.

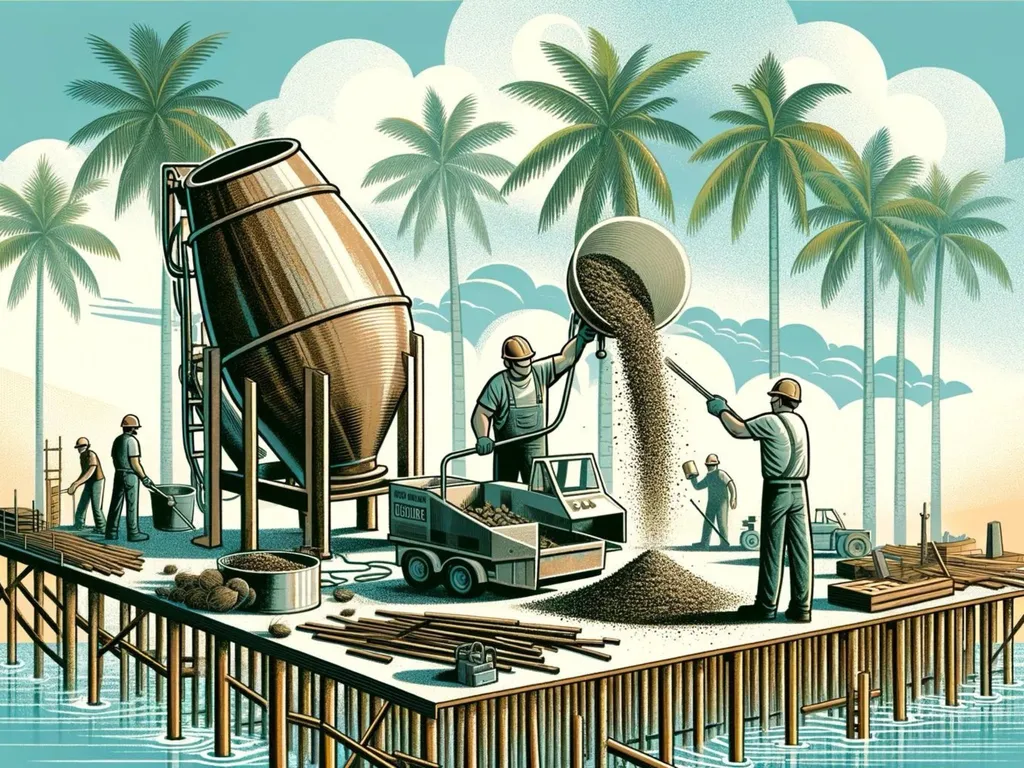

The study involved testing various proportions of CSA in concrete mixes, ranging from 0% to 20% at 5% increments, along with different levels of coconut fiber reinforcements. The results showed that while adding more than 10% CSA decreased the workability and compressive strength of the concrete compared to conventional mixes, the mixes with 5% and 10% CSA still exhibited notable compressive strengths of 29.50 MPa and 26.50 MPa, respectively, after 28 days of curing.

“Our findings suggest that coconut shell ash can be a viable partial replacement for cement, particularly at lower replacement levels,” Maheswari explained. “This not only helps in managing agricultural waste but also contributes to reducing the carbon footprint of the construction industry.”

The commercial implications of this research are significant. As the demand for sustainable building materials grows, the construction industry is increasingly seeking innovative solutions to reduce its environmental impact. The use of CSA as a cement substitute could provide a cost-effective and eco-friendly alternative, particularly in regions where coconut production is prevalent.

Moreover, the incorporation of coconut fibers as reinforcements adds another layer of sustainability. These fibers, derived from agricultural waste, can enhance the tensile strength and durability of concrete, making it a more robust and environmentally friendly construction material.

“This research opens up new possibilities for the construction industry to adopt more sustainable practices,” said Maheswari. “By utilizing agricultural byproducts, we can create a circular economy that benefits both the environment and the industry.”

The study’s findings could shape future developments in the field by encouraging further research into the use of other agricultural byproducts as supplementary cementitious materials. As the construction industry continues to evolve, the integration of sustainable materials like CSA and coconut fibers could become a standard practice, paving the way for a greener and more environmentally conscious future.

In the broader context, this research highlights the importance of interdisciplinary collaboration. By bringing together experts from the agricultural and construction sectors, innovative solutions can be developed to address pressing environmental challenges. As Maheswari’s work demonstrates, the key to sustainability lies in leveraging the resources we already have in new and creative ways.