In the quest for sustainable construction materials, researchers have turned to an unlikely ally: fly ash, a byproduct of coal combustion. A recent study led by Sagar Dattatray Turkane from the School of Civil & Environmental Science at JSPM University in Pune, India, explores the potential of fly ash-based geopolymer to enhance the properties of expansive soils, offering a greener alternative to traditional cement stabilizers.

Expansive soils, characterized by their high and low plasticity, pose significant challenges in road construction. These soils can swell and shrink with changes in moisture, leading to pavement distress and increased maintenance costs. Turkane’s research, published in the journal ‘Advances in Civil and Architectural Engineering’ (which translates to ‘Advances in Civil and Architectural Engineering’), investigates how fly ash-based geopolymer can mitigate these issues, providing a more sustainable solution for road pavements.

The study involved a series of laboratory experiments to evaluate the effectiveness of geopolymer-treated soil. Tests included free swell behavior, shrinkage behavior, unconfined compression, California bearing ratio, and resilient modulus. The results were promising. “The optimized fly ash and geopolymer mixes were noted at 25%,” Turkane explained, highlighting the significant improvements in soil strength and reduction in swelling and shrinkage.

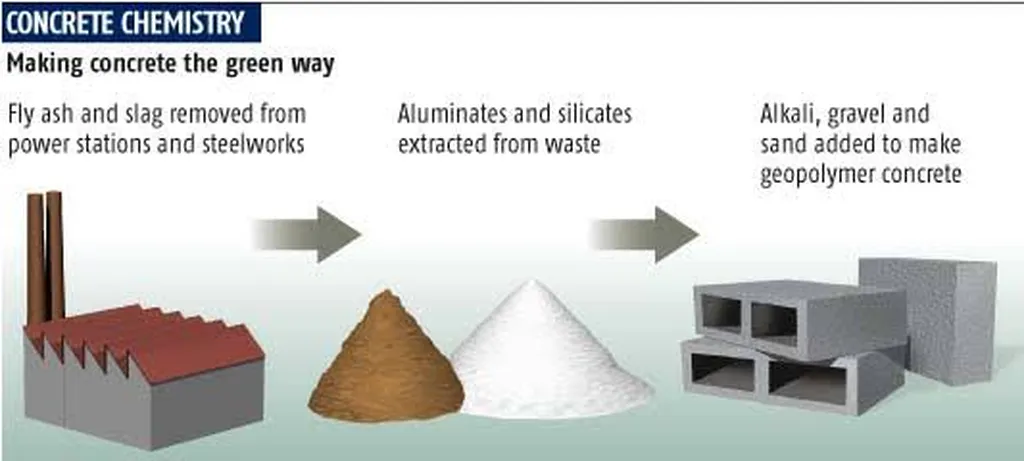

The implications for the construction industry are substantial. By using fly ash, a waste material, to create a valuable construction material, this research contributes to a circular economy. It also reduces the need for conventional stabilizers, which often have a higher environmental footprint. “This material is more suitable for the sub-grade or sub-base layer of flexible pavement,” Turkane noted, pointing to its potential to enhance the durability and longevity of roads.

The commercial impacts for the energy sector are equally compelling. As the world transitions to cleaner energy sources, the demand for coal is expected to decline, potentially leaving vast amounts of fly ash with no useful purpose. This research offers a viable solution for repurposing this material, turning a liability into an asset.

Moreover, the study underscores the importance of soil plasticity in determining the strength of soil. Low-plastic soils, which are typically more mechanically strong, benefit significantly from geopolymer treatment. This finding could guide future construction projects, helping engineers select the most suitable materials for specific soil conditions.

The research also opens up new avenues for further investigation. For instance, how does the geopolymer treatment perform under different climatic conditions? What is the long-term durability of geopolymer-treated soils? Answering these questions could further solidify the role of geopolymer in sustainable construction.

In conclusion, Turkane’s research presents a compelling case for the use of fly ash-based geopolymer in road construction. By enhancing the properties of expansive soils, this innovative material offers a sustainable solution that could reshape the future of the construction industry. As the world grapples with the challenges of climate change and resource depletion, such advancements are not just welcome but essential.