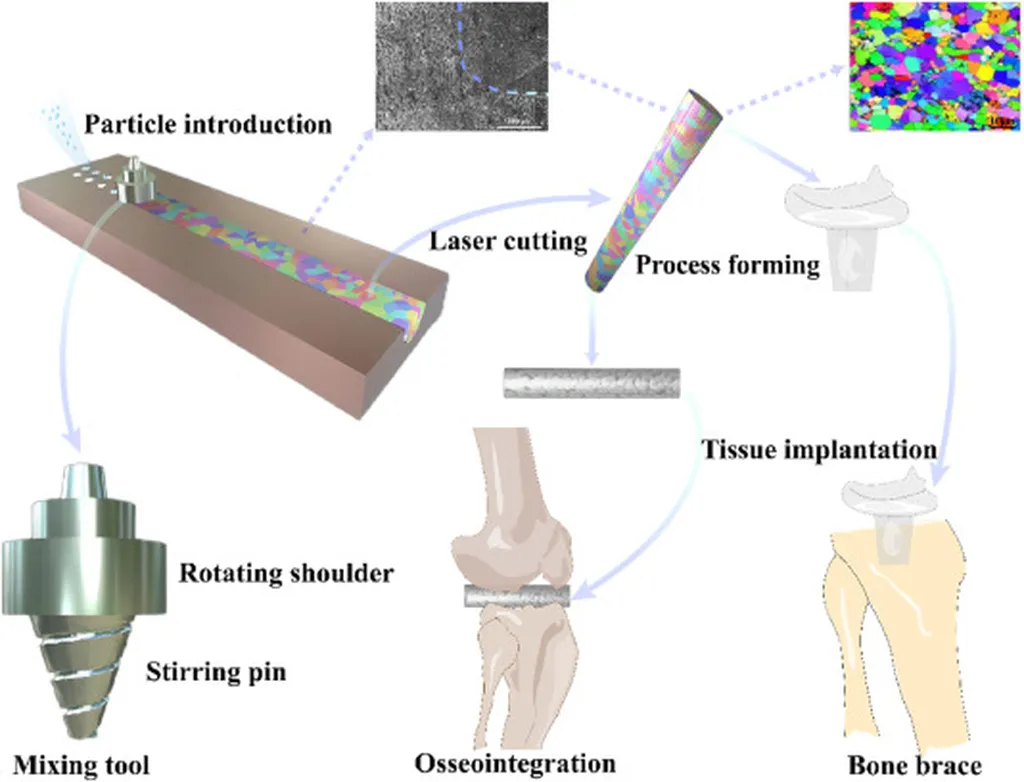

In a significant stride towards enhancing the performance of magnesium alloys for biomedical applications, researchers have uncovered a promising strategy that combines friction stir processing (FSP) and solutionizing heat treatment. This innovative approach has been shown to improve both the mechanical properties and corrosion resistance of ZE41 magnesium (Mg) alloy, paving the way for its potential use in degradable medical implants.

The study, led by Ratna Sunil Buradagunta from the Department of Mechanical Engineering at Prince Mohammad Bin Fahd University in Saudi Arabia, was recently published in the journal “Materials Research Express” (which translates to “Materials Research Express” in English). The research team subjected ZE41 Mg alloy to friction stir processing, a solid-state processing technique known for its ability to refine grain size and improve material properties. Following this, the alloy underwent a solutionizing heat treatment at 335 °C.

The results were striking. The grain size of the alloy was significantly reduced from 86 ± 3.8 μm to just 3.4 ± 1.5 μm after FSP. Post heat treatment, the grain size grew slightly to 6.7 ± 2.2 μm. This grain refinement led to a notable increase in hardness and tensile strength. “The increased tensile strength of 225 ± 16.3 MPa after FSP and 197 ± 10.5 MPa after FSP+HT, compared to the base alloy’s 157 ± 12.8 MPa, is particularly impressive,” Buradagunta noted. Remarkably, these improvements were achieved without sacrificing the alloy’s elongation percentage.

The study also delved into the corrosion resistance of the treated alloys. Electrochemical experiments revealed a lower corrosion current density for the FSP+HT sample, indicating enhanced corrosion resistance. Immersion studies in simulated body fluid further supported this finding, with the FSP+HT sample showing decreased weight loss due to increased biomineralization.

Cell viability tests using African Green Monkey kidney (VERO) cell lines confirmed the non-toxicity of the treated alloys, making them suitable for biomedical applications. “The excellent cell viability across all samples underscores the safety of these treated alloys for potential use in medical implants,” Buradagunta added.

The implications of this research are far-reaching. By improving the mechanical properties and corrosion resistance of ZE41 Mg alloy, this study opens up new possibilities for its use in the energy sector, particularly in applications requiring lightweight, high-strength materials. The enhanced performance of the alloy could lead to more efficient and durable components in various energy-related technologies.

As the demand for sustainable and high-performance materials continues to grow, the findings of this study could shape future developments in the field. The combination of FSP and solutionizing heat treatment presents a viable strategy for optimizing the properties of Mg alloys, potentially revolutionizing their applications in both biomedical and energy sectors.